Low-fat fermented dairy product, preparation method thereof and application of collagen peptide

A technology of fermented dairy products and collagen peptides, applied in dairy products, applications, milk preparations, etc., can solve the problems of low-fat fermented dairy products with poor taste and insufficient smooth texture, and achieve the alleviation of lactose intolerance and balance Effects of intestinal flora and promoting bone health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Low-fat fermented milk ingredients:

[0050] Component A: fresh low-fat milk 30wt%, pectin 0.2wt%, modified starch 0.5wt% and white sugar 11wt%; component B: fresh low-fat milk 40wt% and low-viscosity CMC 0.294wt%; fish skin source Collagen peptide 2wt%; tomato juice 16wt%; fermentation strain: YB0925-A starter 0.006wt%.

[0051] The preparation method of low-fat fermented milk:

[0052] (1) Preparation of material liquid A: Mix and stir component A and collagen peptide at 50°C evenly, stir at a speed of 900 rpm for 15 minutes, perform secondary homogenization at 65°C and 17MPa; Sterilize for 5 minutes; cool to 45°C through the pipe plate;

[0053] Preparation of material liquid B: Mix and stir component B at 60°C evenly, stir at 1600 rpm for 15 minutes, carry out secondary homogenization at 65°C and 20MPa; sterilize at 95°C for 5 minutes;

[0054] (2) Inoculate the fermentation strain in feed liquid A, and the total amount of Streptococcus thermophilus and Lactobaci...

Embodiment 2

[0058] Low-fat fermented milk ingredients:

[0059] Component A: fresh low-fat milk 40wt%, pectin 0.2wt%, modified starch 0.5wt% and white sugar 15wt%; component B: fresh low-fat milk 30wt% and low-viscosity CMC 0.294wt%; fish phosphorus source Collagen peptide 5wt%, blueberry juice 9wt%; fermentation strain: YB-0925B starter 0.006wt%.

[0060] The preparation method of low-fat fermented milk:

[0061] (1) Preparation of material liquid A: Mix and stir component A and collagen peptide at 50°C evenly, stir at a speed of 900 rpm for 25 minutes, perform secondary homogenization at 55°C and 25MPa; Sterilize for 5 minutes; cool to 42°C through a sandwich cylinder;

[0062] Preparation of material liquid B: Mix and stir component B at 65°C evenly, stir at a speed of 1600 rpm for 25 minutes, carry out secondary homogenization at 55°C and 25MPa; sterilize at 90°C for 5 minutes;

[0063] (2) Fermentation strains were inoculated in feed liquid A, and the total amount of Streptococcus...

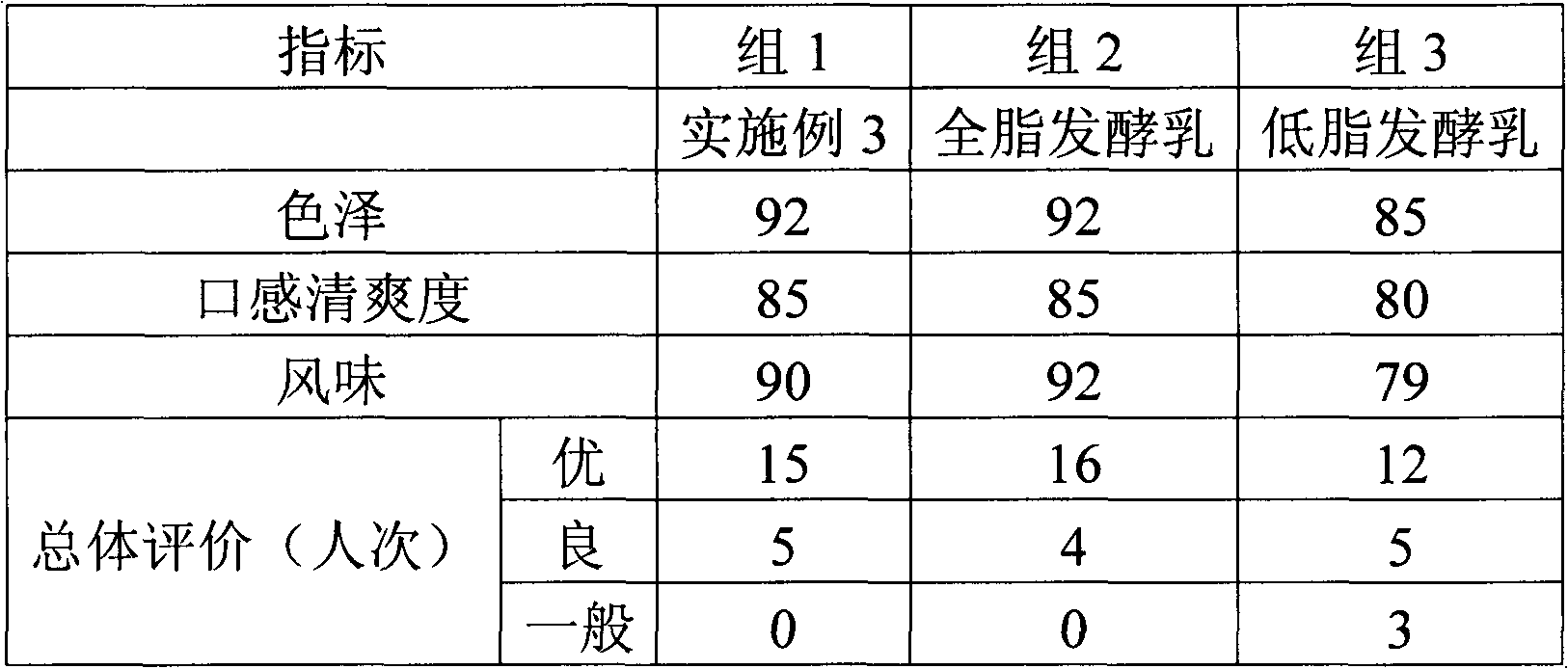

Embodiment 3

[0067] Low-fat fermented milk ingredients:

[0068] Component A: fresh low-fat milk 60wt%, pectin 0.15wt%, gelatin 0.25wt%, modified starch 0.3wt% and white sugar 7wt%; component B: fresh low-fat milk 20wt% and low-viscosity CMC 0.294wt% 3 wt% of collagen peptide derived from cowhide; 9 wt% of blueberry juice; fermentation strain: 0.006 wt% of MM100 starter.

[0069] The preparation method of low-fat fermented milk:

[0070] (1) Preparation of material liquid A: Mix and stir component A and collagen peptide at 45°C evenly, stir at a speed of 1600 rpm for 20 minutes, perform secondary homogenization at 75°C and 20MPa; Sterilize for 5 minutes; cool to 25°C through the pipe plate;

[0071] Preparation of material liquid B: Mix and stir component B at 75°C evenly, stir at a speed of 1200 rpm for 20 minutes, carry out secondary homogenization at 75°C and 20MPa; sterilize at 95°C for 5 minutes;

[0072] (2) Inoculate the fermentation strains in the feed liquid A, the total amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com