Product automatic bagging machine and operation method thereof

A bagging machine and product technology, applied in the direction of single object, transportation and packaging, packaging, etc., can solve the problem that keyboard keys can only be packaged manually, and achieve the effect of reducing labor costs and reducing production costs of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

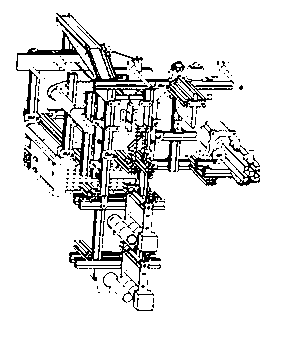

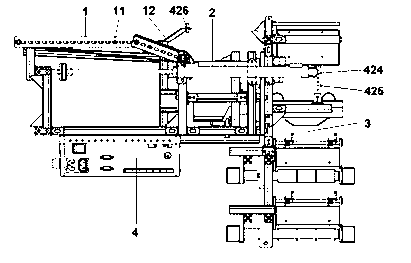

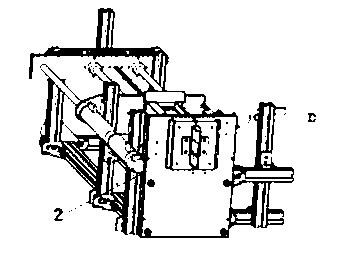

[0029] A specific working principle and process of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] First connect the electricity and gas and turn it on, the product automatic bagging machine will automatically return to the initial waiting state, such as figure 1 , the product enters the transmission part (1) after injection molding, from the transmission part (1) into the adjustment and insertion part (2), in the adjustment and insertion part (2), the product first passes through the rear baffle (211), and then Completely enter the middle part of the adjustment insertion part (2), the optical fiber sensor head (426) senses that there is a product entering, and the electric control part (4) controls the solenoid valve (432) to drive the cylinder (212) to drive the electromagnet (431) (at this time power off suction closed) close the adjustment box (21) cover:

[0031] (1) When setting one product, the rotating powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com