Apple-fragrant color-intrigue super wear-resisting oily elastic paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

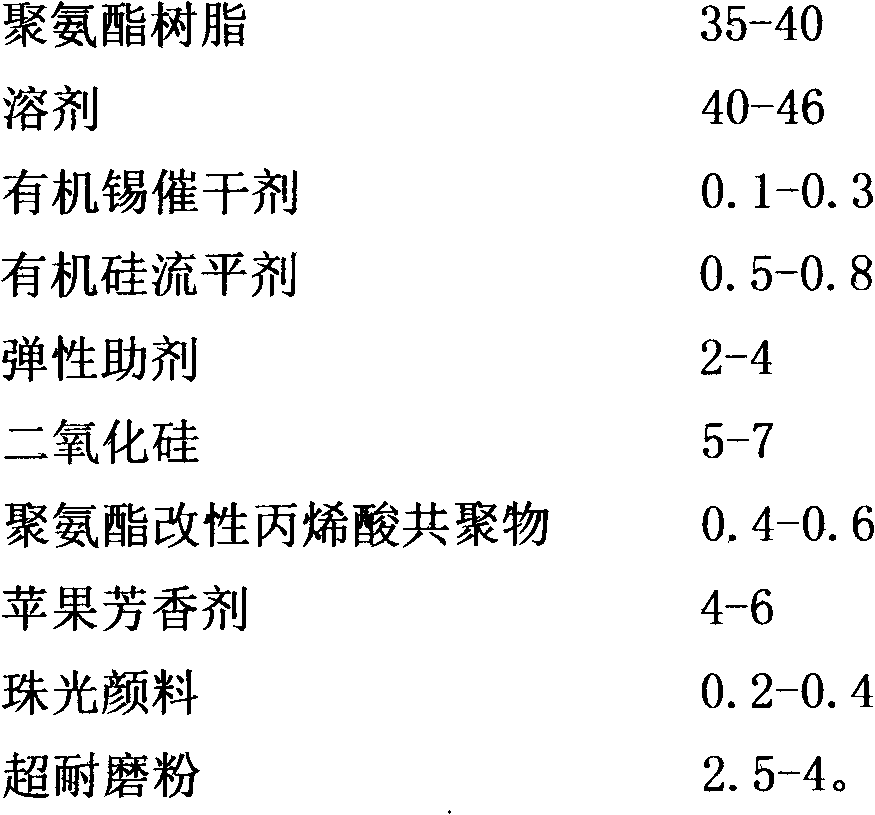

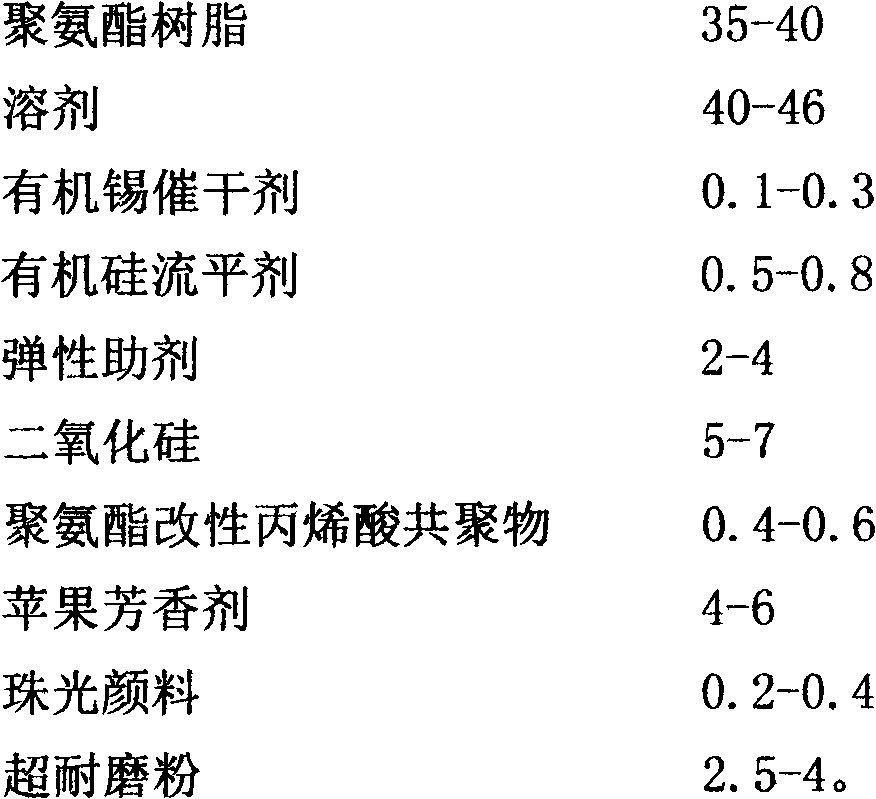

[0018] 1. Take each component according to the following parts by weight:

[0019] Polyurethane resin 38, solvent 43.1, organic tin drier 0.2, silicone leveling agent 0.5, elastic additive 2, silicon dioxide 6.5, polyurethane modified acrylic copolymer 0.5, apple fragrance 4, pearlescent pigment 0.2, super resistant Milling 5

[0020] 2. Follow the steps below for specific configuration:

[0021] First add silicon dioxide into the solvent and soak and stir for 5 minutes;

[0022] Then add polyurethane resin and polyurethane modified acrylic copolymer and stir for 20-30 minutes;

[0023] Finally, add silicone leveling agent, organic tin drier, elasticity aid, apple fragrance, pearlescent pigment, super wear-resistant powder and stir for 10-15 minutes;

[0024] The prepared solution is filtered to obtain the product of the present invention after filtration.

[0025] The oil-based elastic paint prepared by this embodiment can reach more than 500 times in the RCA / 175g test, c...

Embodiment 2

[0027] Take each component by weight fraction as follows:

[0028] Polyurethane resin 40, solvent 40.7, organic tin drier 0.3, silicone leveling agent 0.5, elastic additive 3, silicon dioxide 6.5, polyurethane modified acrylic copolymer 0.5, apple fragrance 4, pearlescent pigment 0.3, super resistant Milling 4, BYK-104S 0.2

[0029] The specific configuration process is the same as that in Embodiment 1.

[0030] As an optimization method of the present invention, in this embodiment, BYK-104S is added to prevent the paint from blooming, so that the product has better workability.

Embodiment 3

[0032] Take each component by weight fraction as follows:

[0033] Polyurethane resin 35, solvent 43.6, organic tin drier 0.1, silicone leveling agent 0.8, elastic additive 3, silicon dioxide 6.5, polyurethane modified acrylic copolymer 0.5, pearlescent pigment 0.3, apple fragrance 4, super resistant Milling powder 4, BYK-104S 0.2, fluff powder 2

[0034] The specific configuration process is the same as that in Embodiment 1.

[0035] As an optimization method of the present invention, in this embodiment, adding fluff powder can make the product have a strong touch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com