Oil well reservoir fracture plugging agent, and preparation method and application thereof

A plugging agent and oil well technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as leakage, buried hill fracture reservoir damage, etc., to achieve safe use and good plugging effect , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The components and weight ratio of the drilling lost circulation agent are: 14% of nylon 66, 15% of DSP-2, 34% of No. 90 asphalt, 14% of delayed expansion agent YH-14%, and 33% of calcium carbonate particles.

[0044] Wherein the components and weight ratio of nylon 66 are: 15-25mm nylon 6675%, 5-15mm nylon 6625%. The composition and weight ratio of No. 90 asphalt are: 50% of No. 90 asphalt of about 1mm, 25% of No. 90 asphalt of about 3mm, and 25% of No. 90 asphalt of about 6mm. The composition and weight ratio of the calcium carbonate particles are: 85% of the 200-mesh superfine calcium particles and 15% of the 3-4mm calcium carbonate particles.

[0045] When preparing, first add DSP-2 into water to fully dissolve to form a base slurry with a viscosity of 100-120S, and then mix it with other components in the formula evenly.

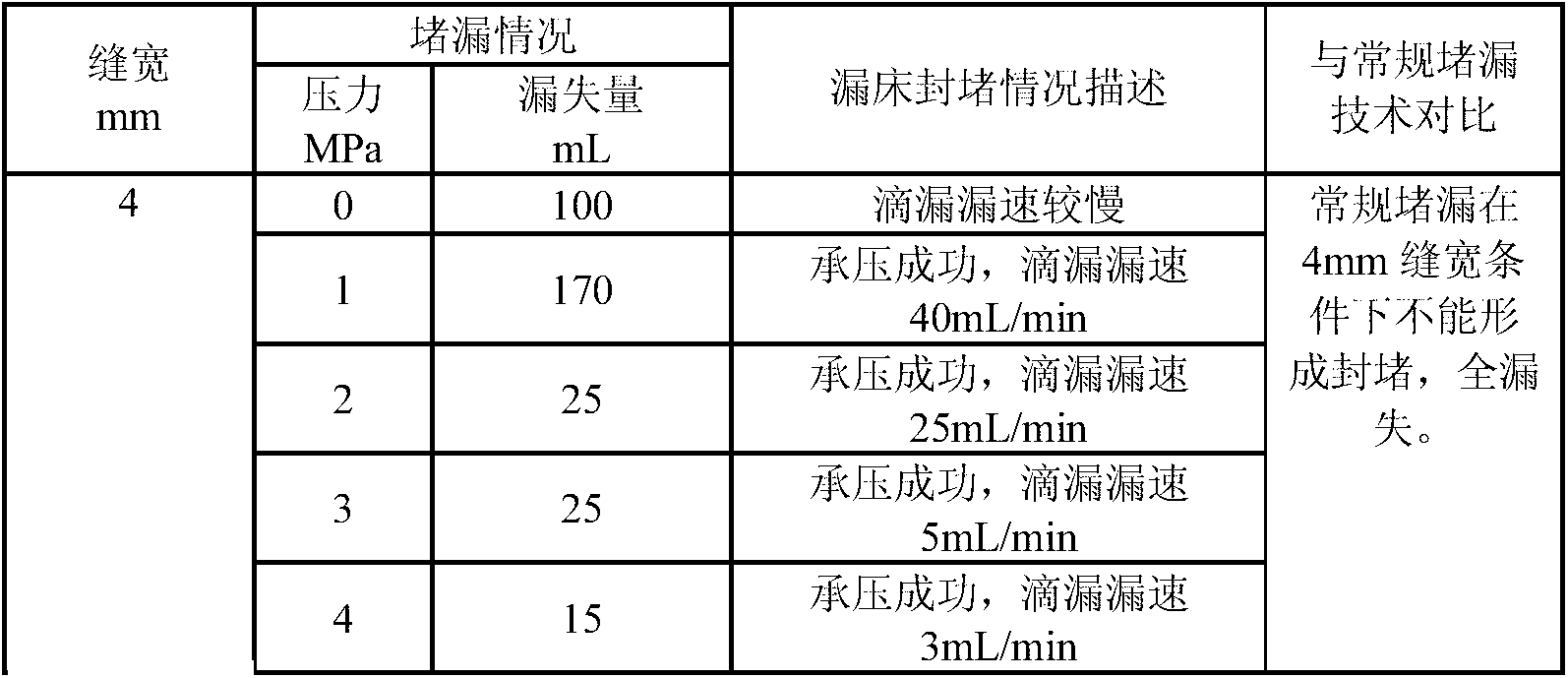

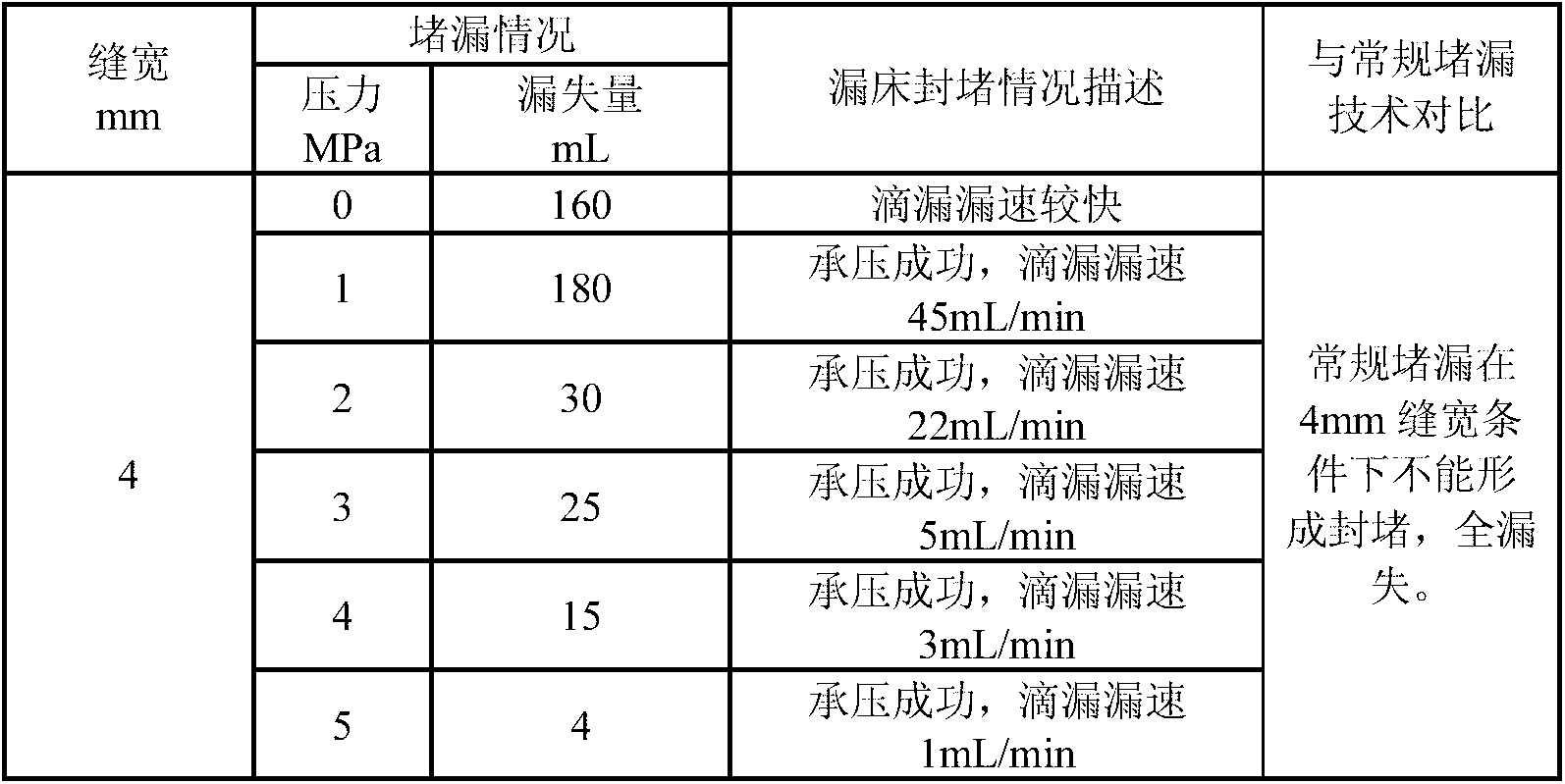

[0046] Aiming at the leakage in the completion process of buried hill wells, the plugging product prepared above was used for a pressure test, ...

Embodiment 2

[0053] Nanpu 23-P2006 is a development well in the buried hill reservoir of Nanpu No. 2 structure, and the main target interval is the Ordovician oil and gas layer in the buried hill. On April 26, 2011, when the well was drilled at a depth of 5235 meters, a leak in a buried hill fracture occurred, and loss of return occurred. The plugging slurry was prepared according to the following formula: nylon 6615%, DSP-210%, No. 90 bitumen 25%, delayed expansion agent YH-14%, calcium carbonate particles 35%, the balance is water.

[0054] Wherein the components and weight ratio of nylon 66 are: 15-25mm nylon 6660%, 5-15mm nylon 6640%. The composition and weight ratio of No. 90 asphalt are: 45% of No. 90 asphalt of about 1mm, 30% of No. 90 asphalt of about 3mm, and 25% of No. 90 asphalt of about 6mm. The composition and weight ratio of the calcium carbonate particles are: 75% of the 200-mesh superfine calcium particles and 25% of the 3-4mm calcium carbonate particles.

[0055] Pump th...

Embodiment 3

[0062] Well Gao 3102-9 is a planned well with three openings and five intervals on the Gao 96 platform. When the well was drilled to 3756 meters, a loss of return occurred suddenly; after two conventional plugging failed, the plugging was carried out according to the following formula: nylon 6610 %, DSP-25%, No. 90 asphalt 25%, delayed expansion agent YH-15%, calcium carbonate particles 34%, and the balance is water.

[0063] The composition and weight ratio of the fiber material are: 15-25mm nylon 6670% and 5-15mm nylon 6630%. The composition and weight ratio of No. 90 asphalt are: 55% of No. 90 asphalt of about 1mm, 25% of No. 90 asphalt of about 3mm, and 20% of No. 90 asphalt of about 6mm. The composition and weight ratio of the calcium carbonate particles are: 65% of the 200-mesh superfine calcium particles and 35% of the 3-4mm calcium carbonate particles.

[0064] The prepared plugging slurry was pumped into the leaky layer, and the leak plugging was stopped when the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com