Gas extraction well location method based on overlying rock fracture shell

A technology of drilling layout and gas drainage, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of short effective drainage time, poor safety, disadvantages, etc., and achieve the reduction of drilling and drainage process and simplify the process Technical links, the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

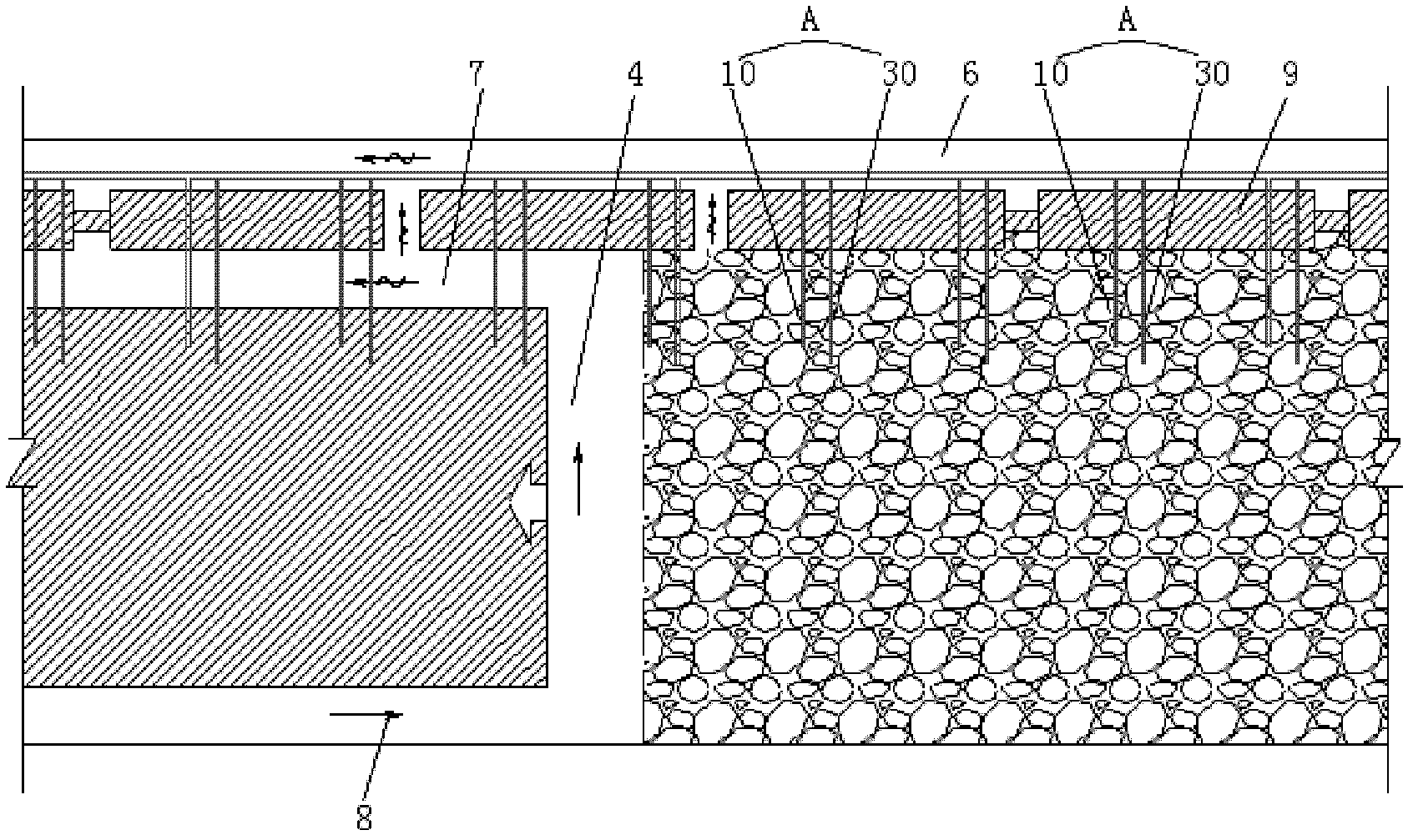

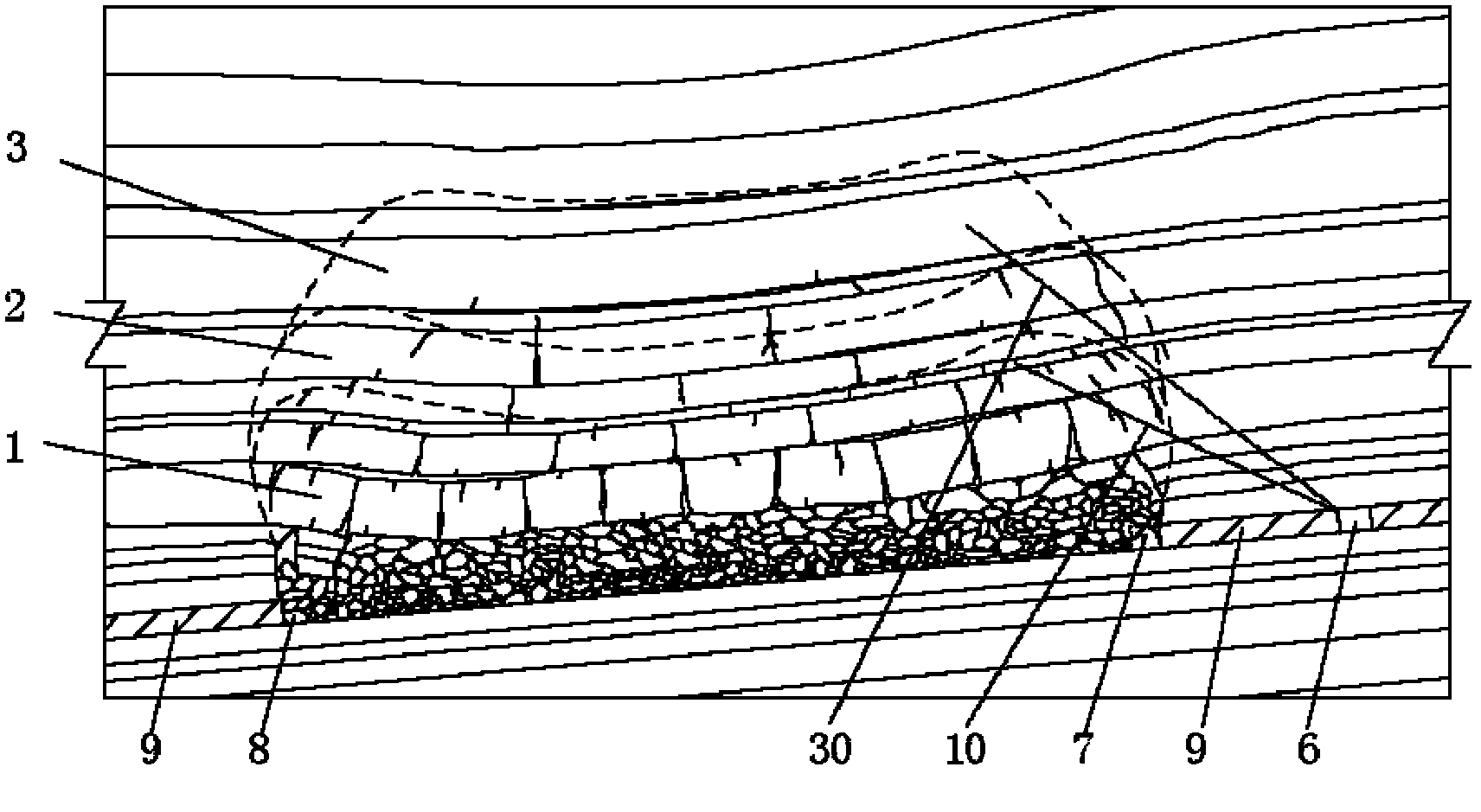

[0020] Such as figure 2 The present invention is based on the principle diagram of the gas drainage drilling layout of the overlying stratum fissure shell, and the present invention divides the gob overlying strata from bottom to top into a low-position fissure shell 1, a middle-position fissure shell 2, and a high-position fissure shell 3. The low-level fractured shell 1 is mainly the vertical fracture development area of the goaf, which is located in the upper part of the caving zone and the lower part of the fractured zone, and has strong vertical penetration. The low-level fractured shell near the working face 4 area is affected by the air leakage of the goaf Larger, the pressure relief gas in the upper and adjacent layers is easy to flow into the caving area 5 under the action of ventilation negative pressure; The lower part of the subsidence zone has strong connectivity in the horizontal direction and is less affected by the air leakage of the goaf. It is a stable ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com