Magnetic valve

A solenoid valve and solenoid coil technology, applied in the field of solenoid valves, can solve problems such as difficult control, and achieve the effects of easy assembly, increased size, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

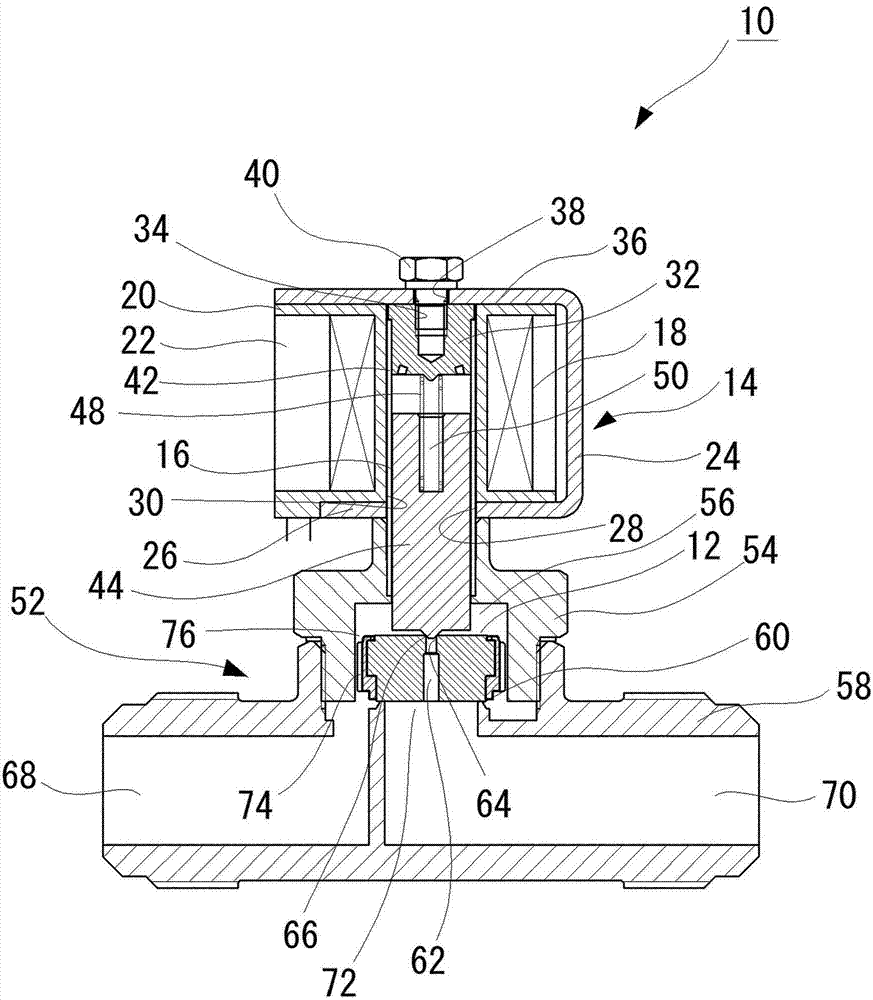

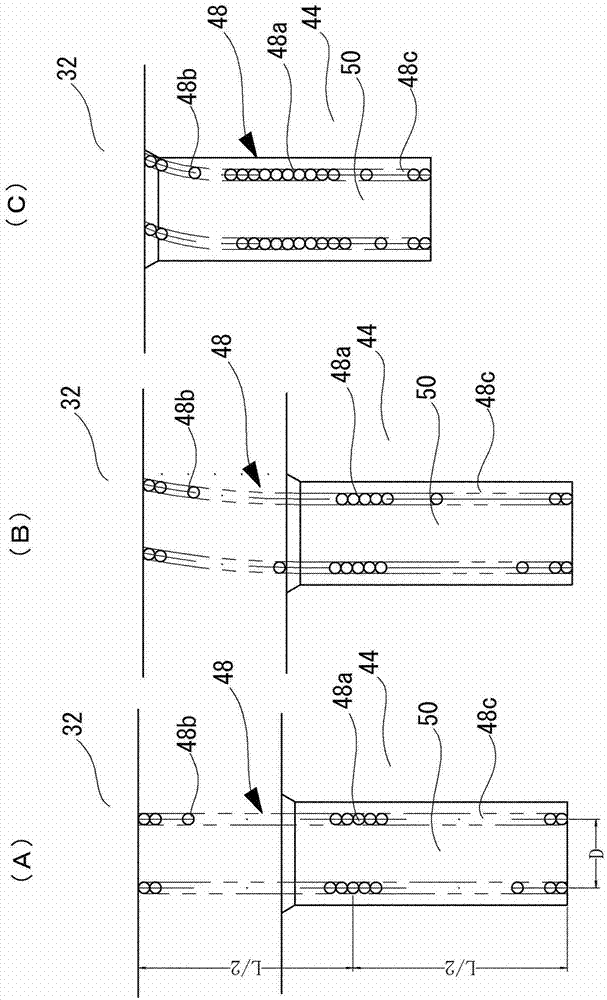

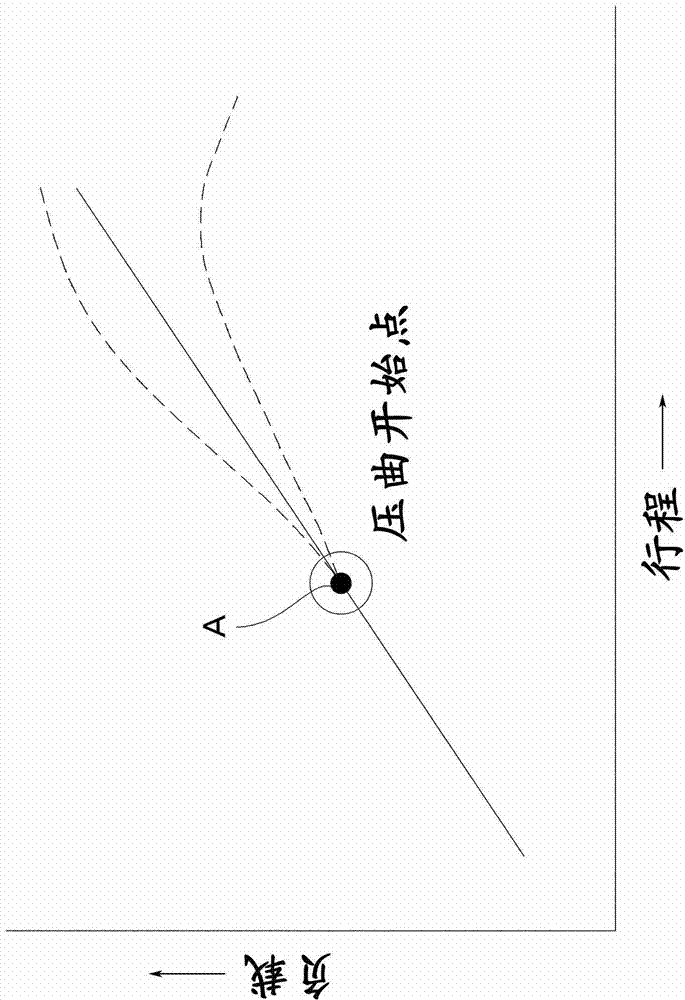

[0090] figure 1 is a schematic longitudinal sectional view of the solenoid valve of the present invention, figure 2 yes figure 1 Partial enlarged cross-sectional view of the solenoid valve, figure 2 (A) is a partially enlarged cross-sectional view showing a state in which the plunger is separated from the attractor and buckling does not occur in a state where the energization of the electromagnetic coil is cut off, figure 2 (B) is a partially enlarged cross-sectional view showing a state in which buckling occurs in a state where energization of the electromagnetic coil is started, figure 2 (C) is a partially enlarged cross-sectional view showing a state in which the plunger is in contact with the attractor when the electromagnetic coil is energized, image 3 It is a graph showing the relationship between stroke and load.

[0091] exist figure 1 In , reference numeral 10 generally indicates the solenoid valve of the present invention.

[0092] The solenoid valve 10...

Embodiment 2)

[0137] Figure 5 is a partially enlarged cross-sectional view of a solenoid valve 10 showing another embodiment of the present invention, Figure 5 (A) is a partially enlarged cross-sectional view showing a state in which the plunger is separated from the attractor and buckled in a state where the energization to the electromagnetic coil is cut off, Figure 5 (B) is a partially enlarged cross-sectional view showing a state where buckling occurs when the electromagnetic coil is started to be energized, Figure 5 (C) is a partially enlarged cross-sectional view showing a state in which the plunger is in contact with the attractor when the electromagnetic coil is energized.

[0138] The configuration of the solenoid valve 10 of this embodiment is basically the same as that of the solenoid valve 10 shown in the first embodiment, and the same components are assigned the same reference numerals, and detailed description thereof will be omitted.

[0139] In the solenoid valve 10 of...

Embodiment 3)

[0143] Image 6 is a partially enlarged cross-sectional view of a solenoid valve 10 showing another embodiment of the present invention, Image 6 (A) is a partially enlarged cross-sectional view showing a state in which the plunger is separated from the attractor and buckling does not occur in a state where the energization of the electromagnetic coil is cut off, Image 6 (B) is a partially enlarged cross-sectional view showing a state in which the plunger is in contact with the attractor when the electromagnetic coil is energized.

[0144] The configuration of the solenoid valve 10 of this embodiment is basically the same as that of the solenoid valve 10 shown in Embodiment 1, and the same components are assigned the same reference numerals, and detailed description thereof will be omitted.

[0145] In the solenoid valve 10 of this embodiment, as Image 6 As shown in (A), the attractor 32 has a substantially conical fitting protrusion 32 a that protrudes toward the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com