Wind tunnel experiment method of pulverized coal piling-up dusting rules

A kind of wind tunnel experiment and experimental technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of raw material loss, air pollution, and less research on dust emission under loading and unloading operations, and achieve Ease of implementation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, it is necessary to carry out the following analysis to the dust law theory of coal dust loading earlier:

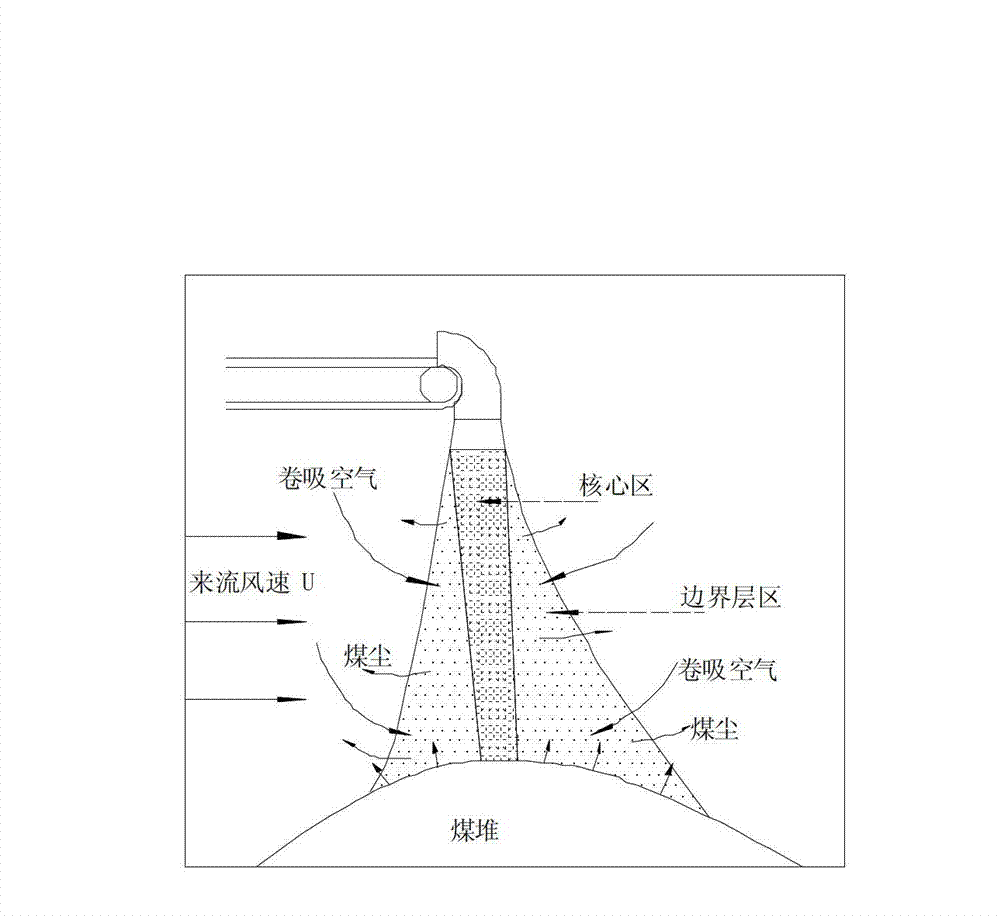

[0028] There are two main mechanisms of dust production in the process of pulverized coal stacking: (1) the escape of tiny particles during the falling process; (2) the entrainment air released when the falling particle flow hits the stack takes away some fine particles. During the falling process of pulverized coal particles, with the acceleration and expansion of the pulverized coal particle plume, air is entrained into the particle flow, and many coal particles with smaller particle sizes, and the entrained ambient air are at the core of the particle plume. The periphery of the region is mixed to form a boundary layer covered with coal dust, and the radius of the boundary layer increases with the height of the descent, see figure 1 . When the fine coal particles located in the boundary layer area are subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com