Potentiometer automatic assembly equipment

An automatic assembly, potentiometer technology, applied in resistors, assembly machines, metal processing equipment, etc., to achieve the effect of less labor, accurate step distance, and light labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

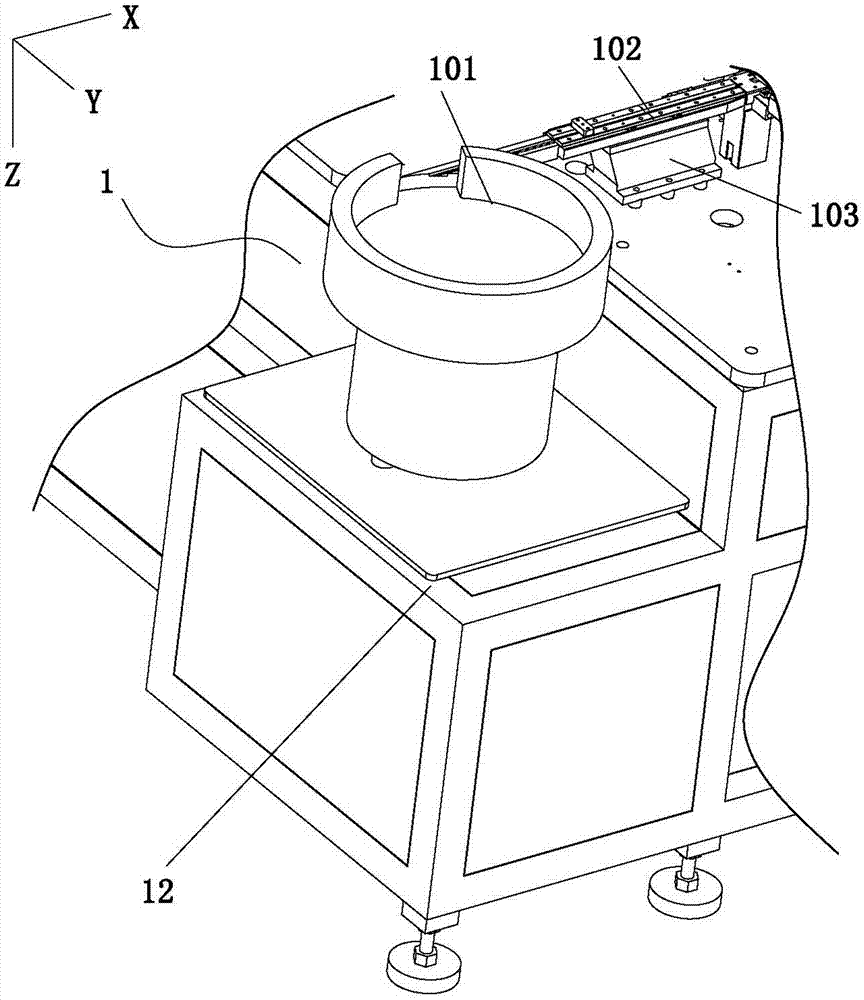

[0035] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

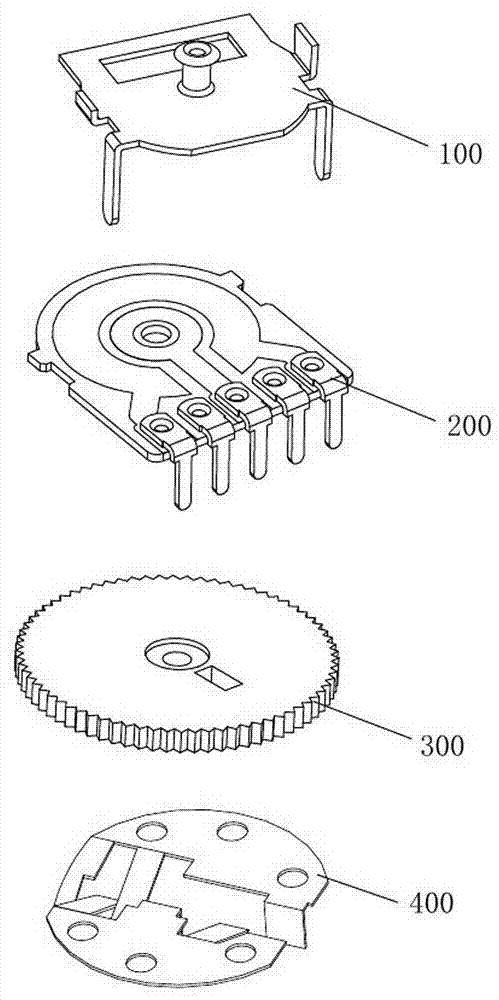

[0036] figure 1 It is an exploded schematic diagram of assembling a product potentiometer, and the bracket 100, the carbon sheet 200, the rotary disk 300 and the brush 400 are automatically assembled into a potentiometer through the present invention.

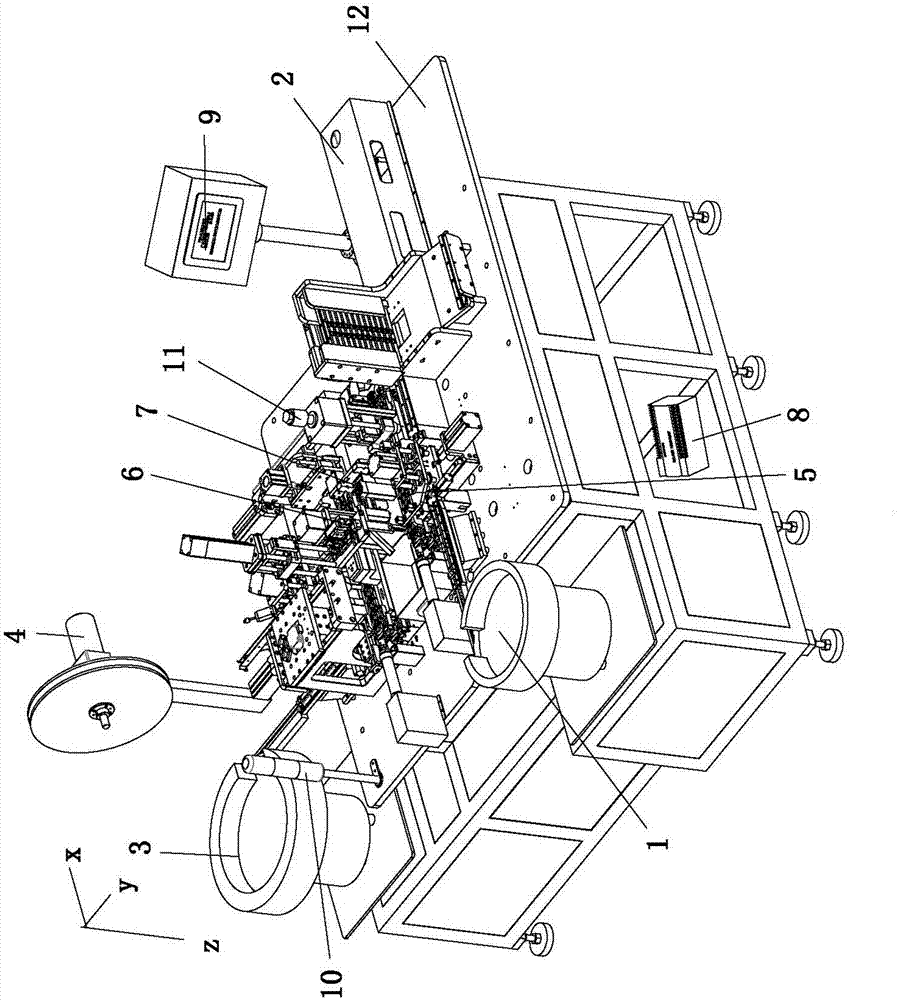

[0037] Such as figure 2As shown, the potentiometer automatic assembly equipment of the present invention includes a bracket conveying device 1, a carbon sheet conveying device 2, a rotary disk conveying device 3, a brush conveying device 4, a bracket and a carbon sheet assembly unit 5, a rotary disk and a brush assembly unit 6, and an overall The product assembly unit 7, the PLC module 8 and the man-machine interface 9 are all arranged on the machine platform 12; wherein, the support conveying device 1 and the carbon sheet conveying device 2 are arranged oppositely along the X direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com