Ray detector and manufacturing method thereof

A ray detector and substrate technology, applied in the field of detectors, can solve problems such as complex production process, long production cycle, and low sensitivity, and achieve the effects of improving sensitivity, reducing production cost, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

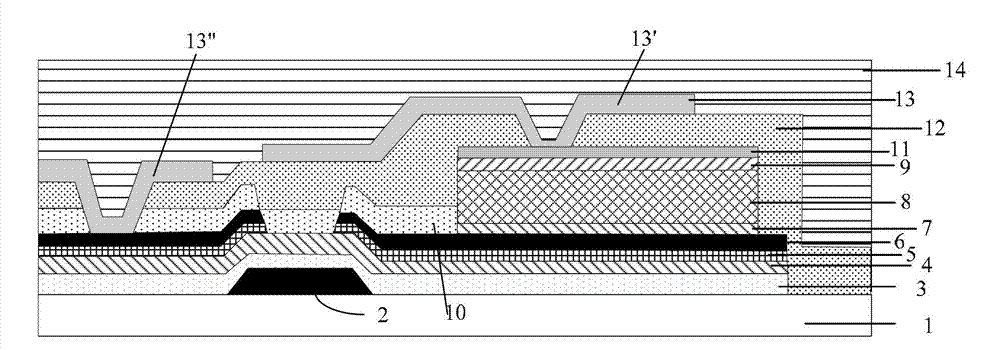

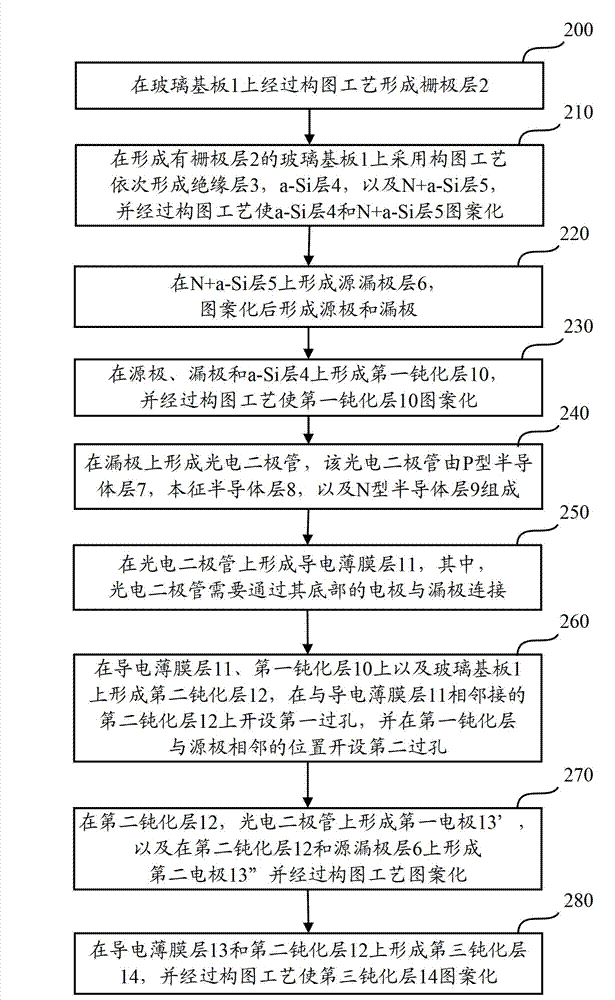

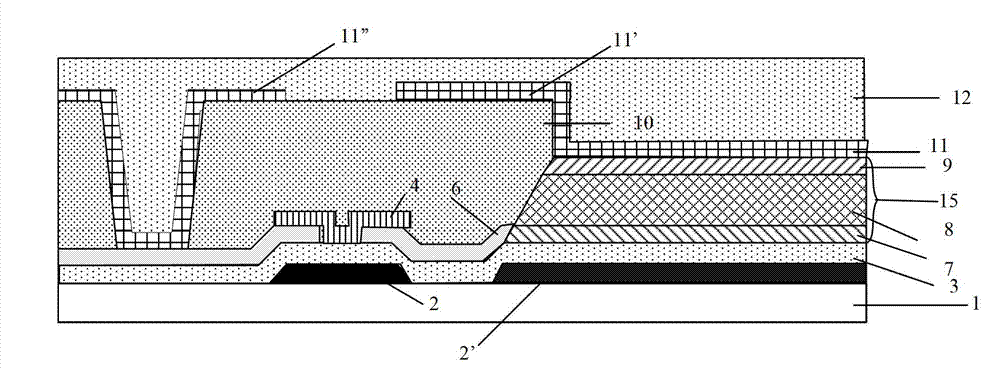

[0046] In order to solve the problems of complex manufacturing process, long manufacturing cycle, low sensitivity and high power consumption of the radiation detector existing in the prior art.

[0047] In the embodiment of the present invention, a gate layer and an insulating layer are sequentially formed on the substrate, and a photodiode and a source-drain layer are formed on the substrate on which the insulating layer is formed; connected; forming an active layer on the above-mentioned source-drain layer, so that the active layer is in contact with the insulating layer; forming a first passivation layer on the above-mentioned active layer and on the above-mentioned source-drain layer, and A via hole is opened on the first passivation layer; on the photodiode, a conductive film layer is formed on the first passivation layer and in the via hole, and a second passivation layer is formed on the conductive film layer. Compared with the prior art, the technical solution of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com