Tower-type solar energy heliostat bevel gear passive automatic sun-chasing support

A technology of tower-type solar energy and bevel gears, which is applied in the field of concentrating solar thermal power generation, concentrating photovoltaics, and tower-type concentrating solar heat collection, and can solve the problems of complicated and cumbersome operation and installation of heliostat tracking mechanisms , to achieve the effects of simple installation and operation regulation, improved accuracy, and simplified control procedures and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

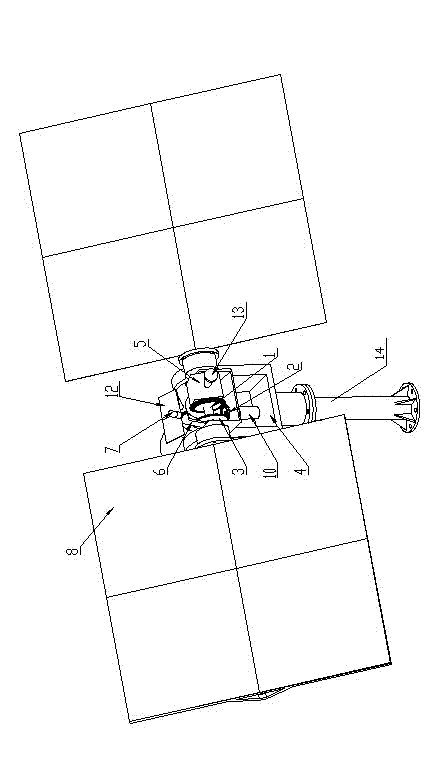

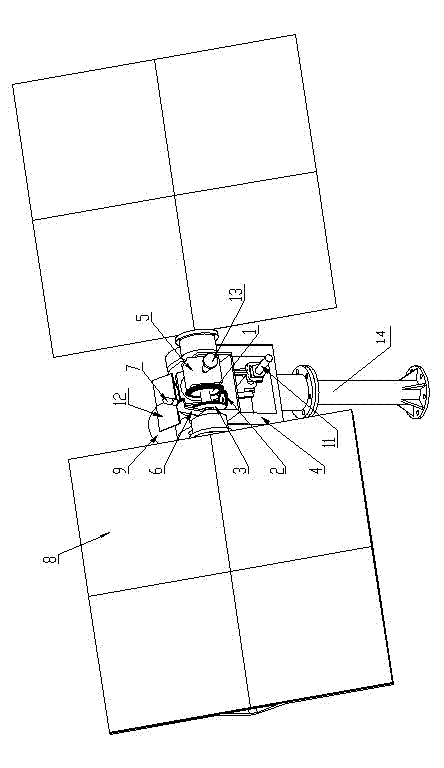

[0035] Embodiment one, such as figure 1 with figure 2 Shown: the pitch rotation reducer 10 is installed on the gear seat 4, and the transition bevel gear 2 of its rotation output shaft is coaxially fixed, and the transition bevel gear 2 will be used as the active driving power source in the pitch direction of the bracket, and the positive drive of the pitch rotation reducer 10 Reversing the rotation will cause the heliostat 8 to pitch.

Embodiment 2

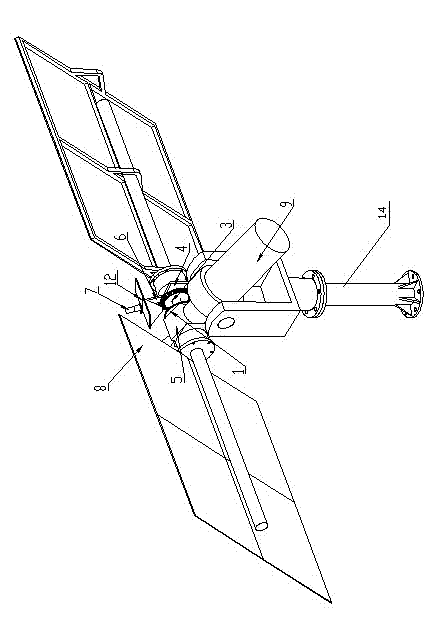

[0036] Embodiment two, such as image 3 with Figure 4 As shown: the fixed end of the linear driver 11 is fixed on the reflection shaft 5, and the moving end of the nut is connected to the gear seat 4. At this time, the linear driver 11 is also used as the active driving power source in the pitch direction of the bracket, through the front and rear of the linear driver 11 nut. The linear motion will drive the heliostat for pitching motion.

[0037] In this way, the photoelectric probe 7 on the incident axis 6 is aimed at the direct sunlight direction through the rotation of the main rotation speed reducer 9 of the support and the pitch motion of the pitch rotation speed reducer 10 or the linear drive 11. According to the movement relationship between the reflective bevel gear 1 and the incident dimension gear 3 and the gear seat 4, the sunlight can shoot to the heliostat along the incident axis 6 and make the reflected light shoot out along the axial direction of the reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com