Honeycomb structure ceramic particle filter screen

A technology of ceramic particles and honeycomb structure, applied in the direction of dispersed particle filtration, dispersed particle separation, deodorization, etc., to achieve the effect of good sterilization and removal of harmful chemicals, simple and convenient process, and high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

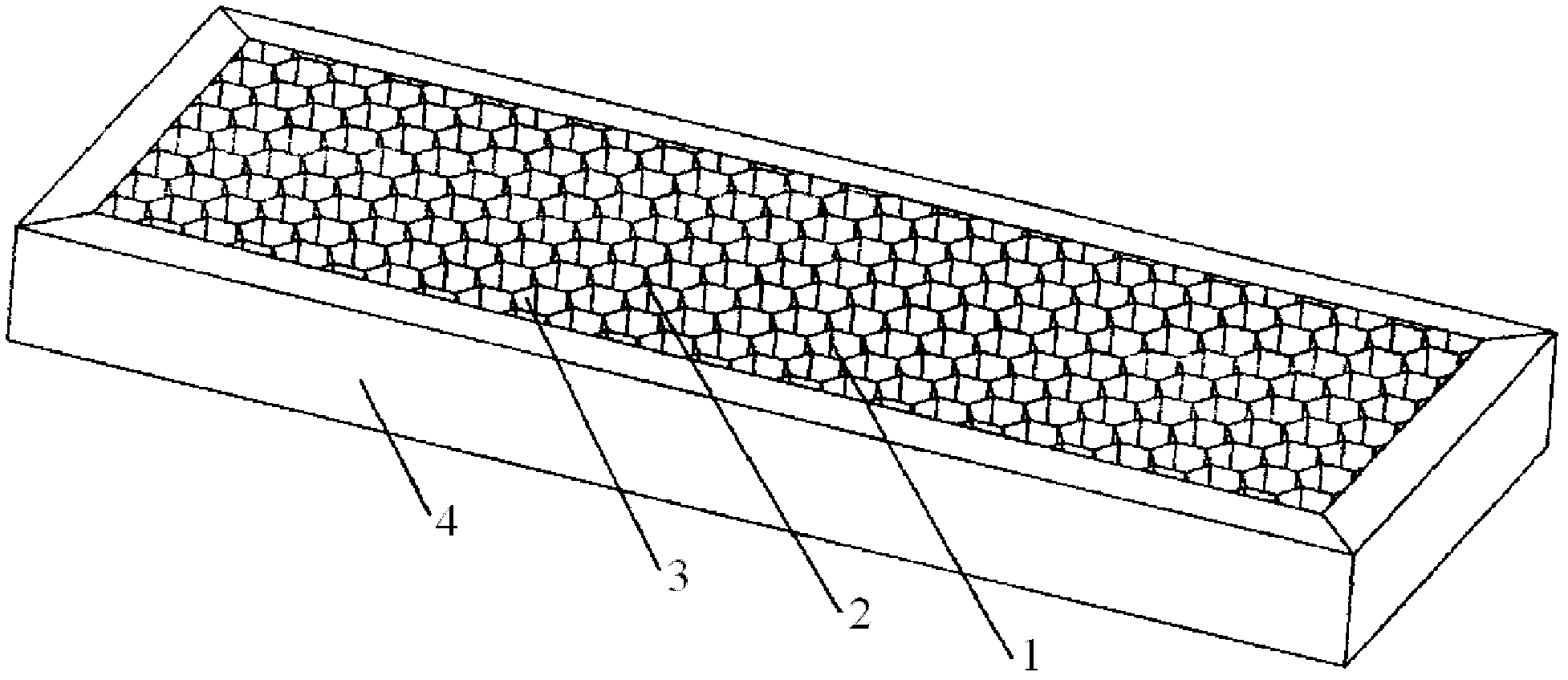

[0024] A honeycomb structure ceramic particle filter screen, its structure is as follows figure 1 As shown, the filter net includes a base material 1 on which a plurality of honeycomb holes are arranged, and the shape of the honeycomb holes can be circular or hexagonal. One side of the substrate is glued with a layer of fibrous net 2 with a hole diameter of 1-2mm. Porous purification ceramics 3 containing photocatalytic functional materials are evenly placed in the honeycomb holes according to specific requirements. The ceramic particles have strong physical adsorption performance and excellent sterilization and removal of harmful chemical substances, which greatly improves air purification. Efficiency is the main filter material of this filter screen device. Continue to stick a layer of fibrous net 2 on the reverse side with hot melt adhesive, so that the base material, the bottom surface and the upper cover are closely combined, thereby sealing the porous ceramics with puri...

Embodiment 2

[0026] A honeycomb structure ceramic particle filter screen, which is composed of a base material, a frame, a bottom surface, an upper cover and a filter material. The material is disposed within the substrate. The filter is a hollow cuboid structure with a length and width of 20-100cm and a thickness of 0.5-2cm, which can be adjusted according to actual needs. The bottom surface, upper cover and base material are tightly bonded with hot-melt adhesive, and the base material and frame are used with hot-melt adhesive. or mechanically tightly coupled.

[0027] The filter material is dispersed in the base material, and the filter material adopts porous purification and adsorption ceramic particles, contains photocatalytic functional materials, is spherical in shape, and has a particle diameter of 2-3mm. The setting density is adjusted according to the usage requirements. The base material is a honeycomb structure, and the shape is hexagonal or circular. The material used for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com