Internal oil injection vertical type hole honing rod

A kind of honing and vertical technology, which is applied in the direction of honing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy breaking of honing rods, difficulties in design and manufacture, and insufficient strength of honing rods, so as to save replacement time, facilitate processing, The effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

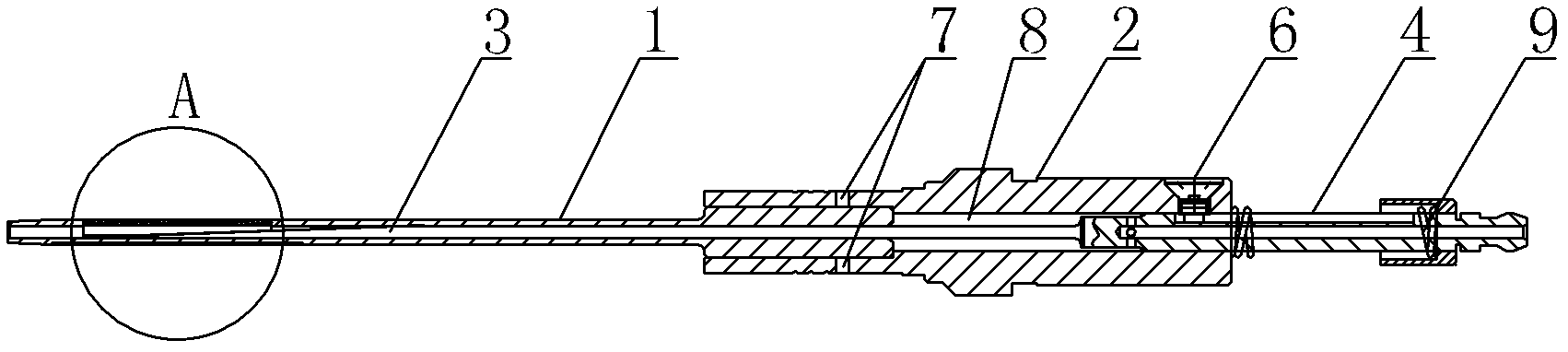

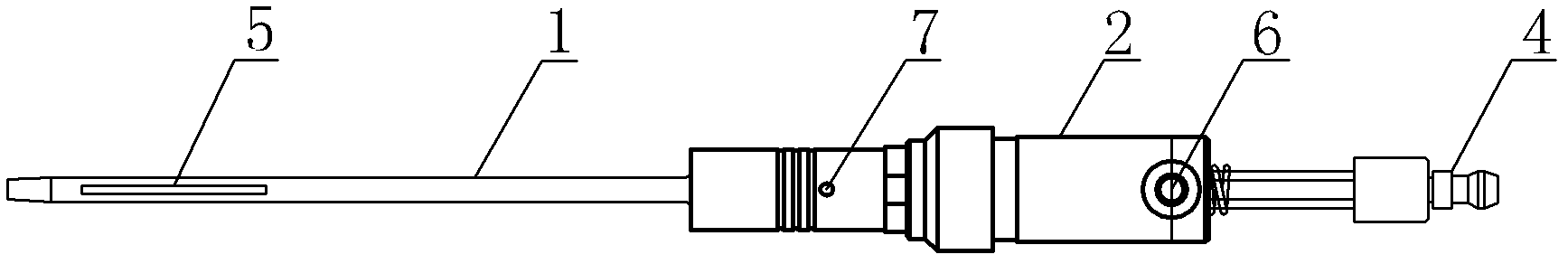

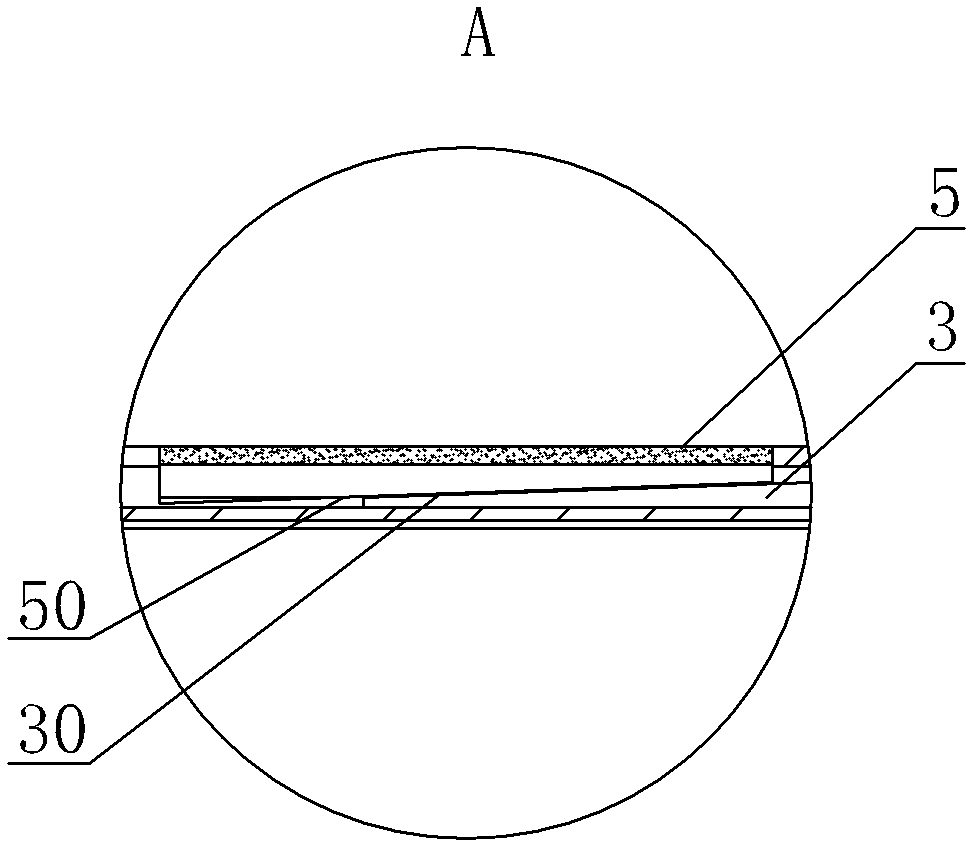

[0018] Such as figure 1 , 2 , 3 shows a kind of inner oil injection type small hole honing rod, which includes a honing rod body 1, a socket 2 sleeved on the honing rod body 1, the honing rod body 1 is made of SKS3 alloy tool steel, and SKS3 is heat-treated It is suitable for manufacturing cutting tools with small deformation, long length and complex shape; the length of honing rod body 1 can be selected as 30mm according to experience and honing principle. The connection between the honing rod body 1 and the socket 2 is convenient for processing, can ensure coaxiality, and saves materials and processing time.

[0019] The honing rod body 1 is provided with a push rod 3 and a push cone 4 that pushes the push rod 3 to feed. The honing rod body 1 is provided with a guide bar 5. The guide bar is made of hard alloy, and the hard alloy can greatly extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com