Auxiliary curing method for cold weather concrete by electric heating tapes

A technology of electric heating belt and concrete, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of large components, inconvenient on-site use, high number of building floors, etc., and achieve high heating efficiency, energy saving, and less heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

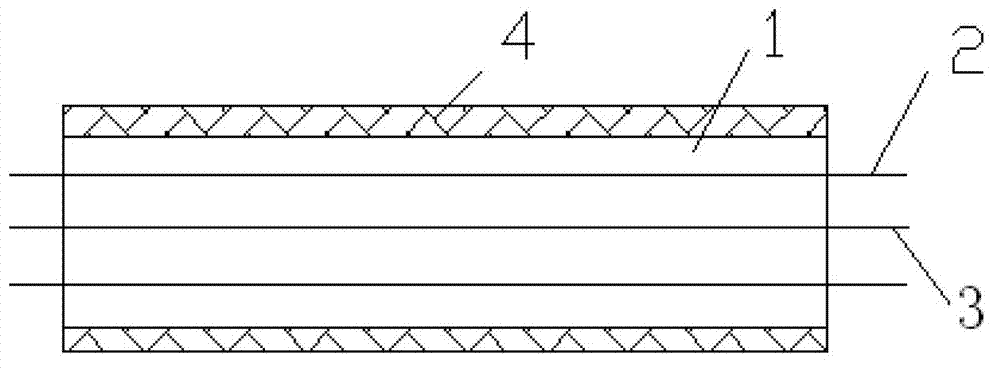

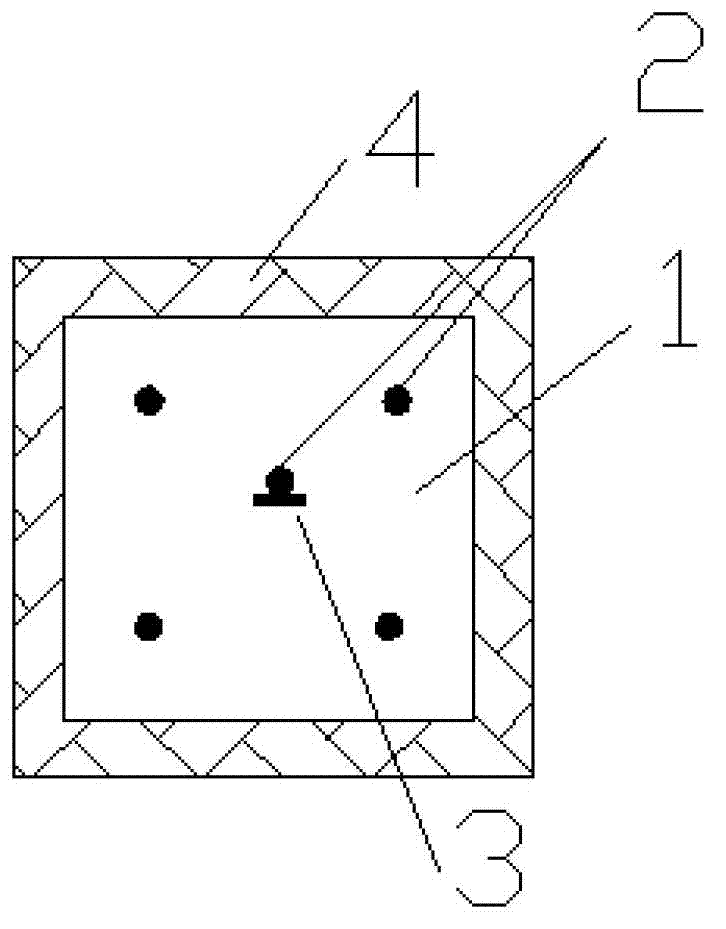

[0016] Such as figure 1 , figure 2 As shown, a winter concrete electric heating belt auxiliary maintenance method is characterized in that it is carried out in the following steps: (1) first support the formwork, after completing the installation of the steel bars 2 of the cast-in-situ concrete member 1 and the placement and welding of the embedded parts, the in-situ The self-limiting temperature electric heating belt 3 is laid in the cast-in-place concrete member 1 and fixed on the steel bar 2 with a fixing belt; according to the size, size and structural form of the cast-in-place concrete member, the self-limiting temperature electric heating belt is evenly and continuously arranged in the cast-in-place concrete member ;The self-limiting temperature electric heating belt is placed in the concrete, and it is not allowed to contact the formwork; Material 4. After the coveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com