Central-shaft torque sensing device for electric bicycle

A technology of electric bicycles and sensing devices, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve the problems of inaccurate output of induced potential signals, poor measurement accuracy, and non-zero startup, etc., and achieve stable working performance Reliability, high sensitivity and high precision, the effect of ensuring driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

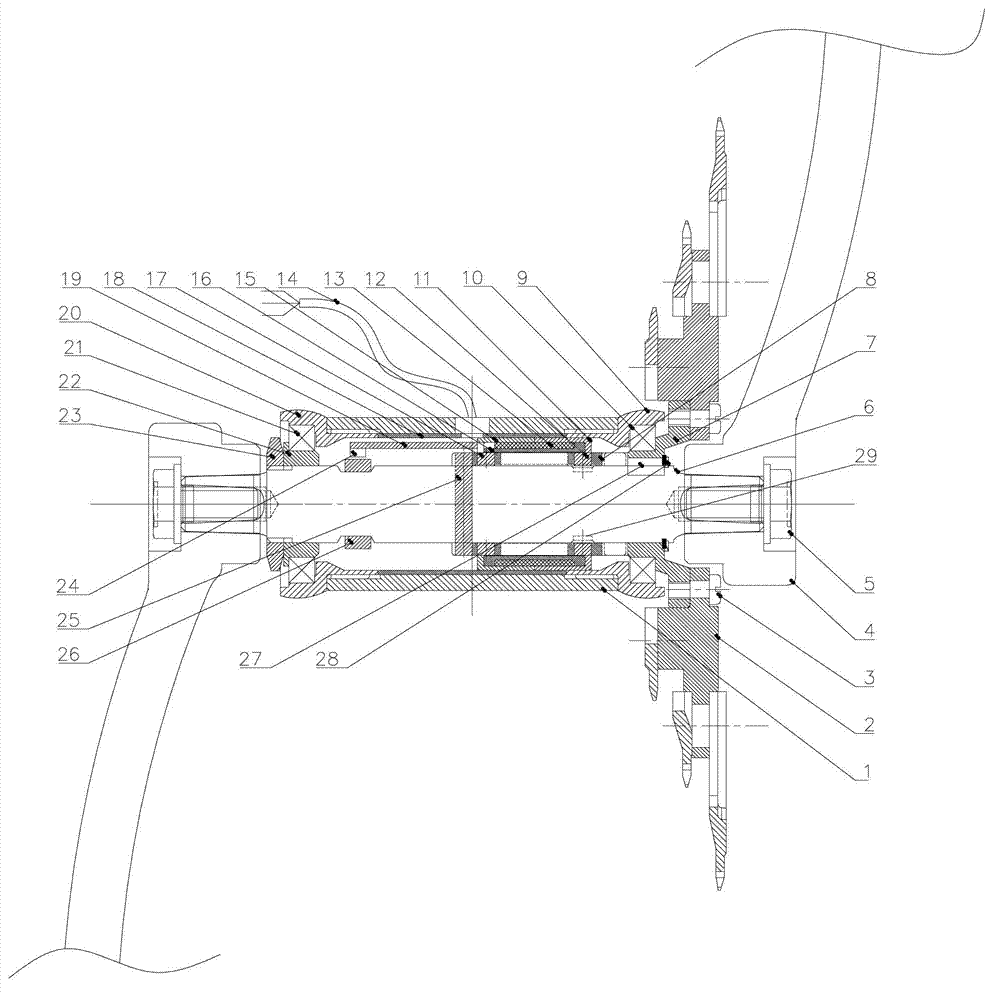

[0023] figure 1 A specific embodiment of the torque sensor device for the center shaft of the electric bicycle of the present invention is shown. 7. Ring sleeve 8, right wrist guard 9, right deep groove ball bearing 10, right magnetic ring 11, right torque sensing magnet 12, coil 13, lead wire 14, left magnetic ring 15, coil support 16, left Torque sensing magnet 17, bushing 18, circuit board 19, left wrist guard 20, left deep groove ball bearing 21, bearing bush 22, hex nut 23, speed sensing Hall 24, fixing pin 25, speed sensing magnet 26, limit key 27 and these parts of axle clip spring 28 are made up of.

[0024] Same as the conventional technology, the bottom bracket 1 is pierced with a central axis 6, and the two ends of the central axis 6 are fixed with cranks 4 through the crank fixing bolts 5, and at the same time, the central axis 6 is sleeved with a tooth plate 2. The disc 2 is located on the right side of the five-way tube 1, and the two ends of the five-way tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com