Edge sealing structure and sealing method of sandwich glass

A technology of laminated glass and sealing structure, applied in the field of metal paint layer, can solve the problems of edge opening of laminated glass, poor air tightness of silicone glue, poor barrier property, etc., and achieves improved waterproof and anti-pollution, good sealing layer performance and easy process. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

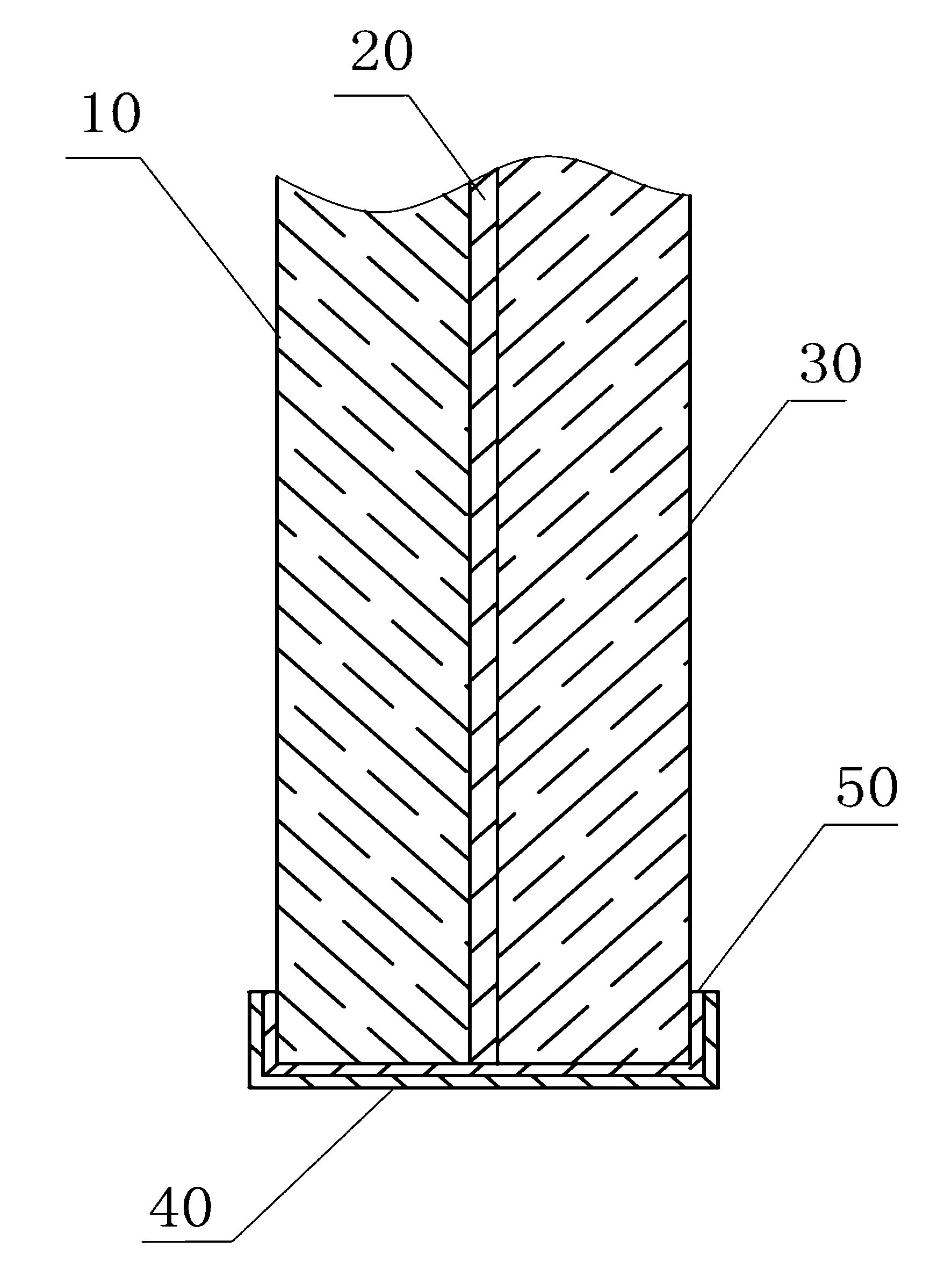

[0039] In the edge sealing structure of the laminated glass of the present invention, a covering and sealing layer is provided on the edge surface of the laminated glass, and the covering and sealing layer is a metal foil layer, or a metal coating tape layer, or a metal oxide coating tape layer, or It is a metallic paint layer.

[0040] In this embodiment, the laminated glass is a laminated glass for construction that meets the national standard GB 15763.3-2009. Covering and sealing layers are provided on the four side surfaces of the laminated glass. If the laminated glass is triangular or polygonal, the cover and sealing layers are provided on the three (or more) side surfaces of the laminated glass.

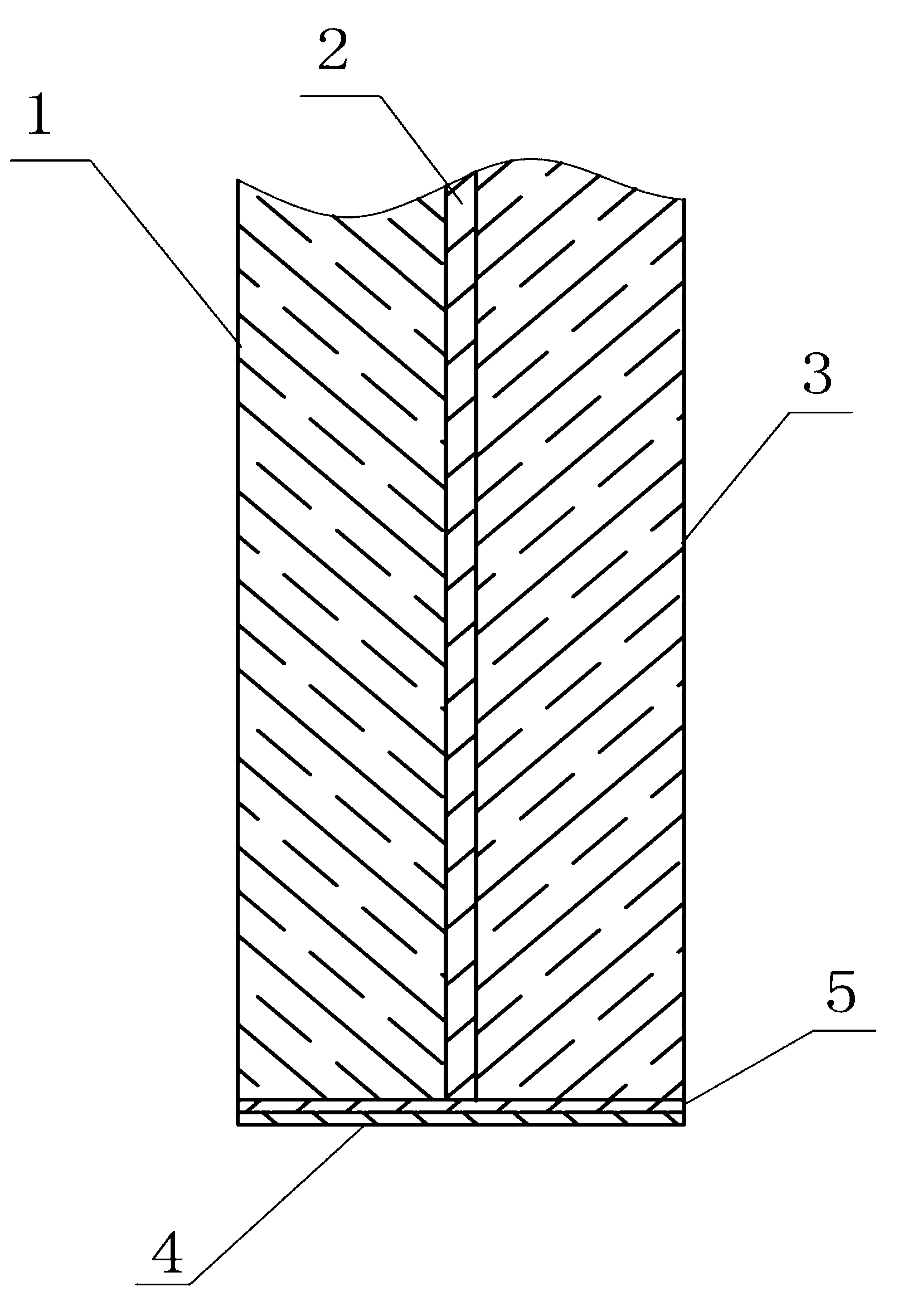

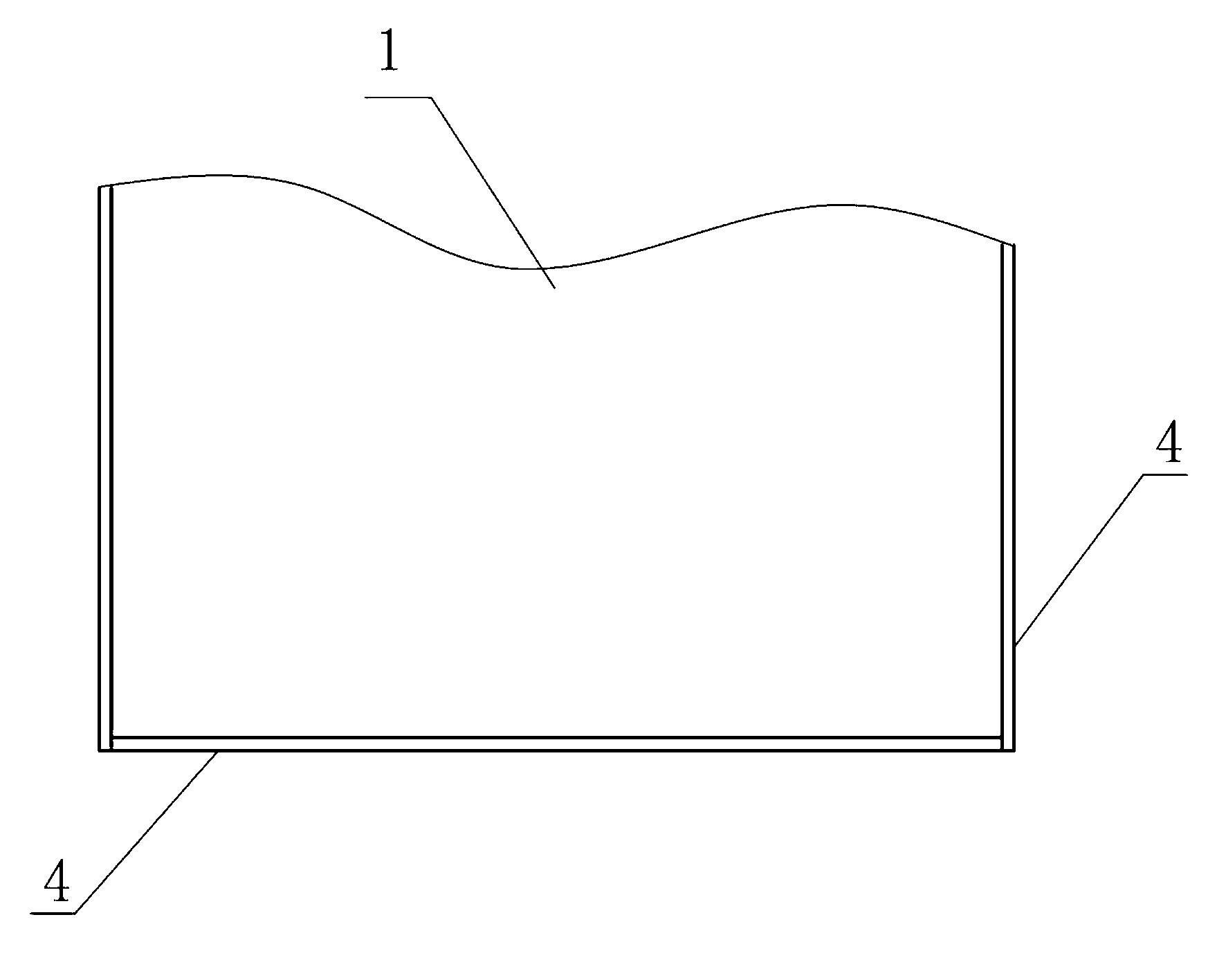

[0041] See figure 1 (Cross-sectional view), figure 2 (Only 3 sides are shown), the laminated glass used in conventional engineering has a rectangular shape, with a left transparent glass plate 1, a right transparent glass plate 3, and a thermosetting transparent adhesive layer 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap