An ultra-low frequency shock-resistant metamaterial vibration isolation device

A metamaterial, impact-resistant technology, applied in the field of vibration reduction and noise reduction, can solve the problems of increasing the design difficulty and cycle of vibration isolators, unstable position control, and excessive airbag chamber volume and displacement, and achieve adaptive protection. Function, strong impact resistance, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

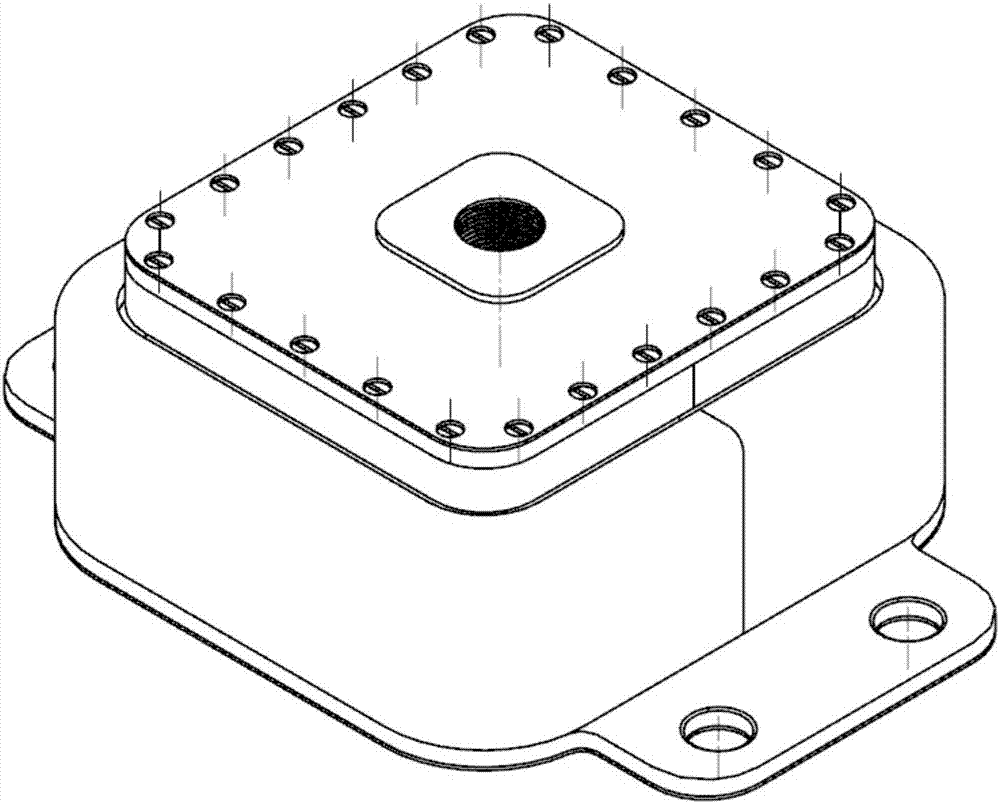

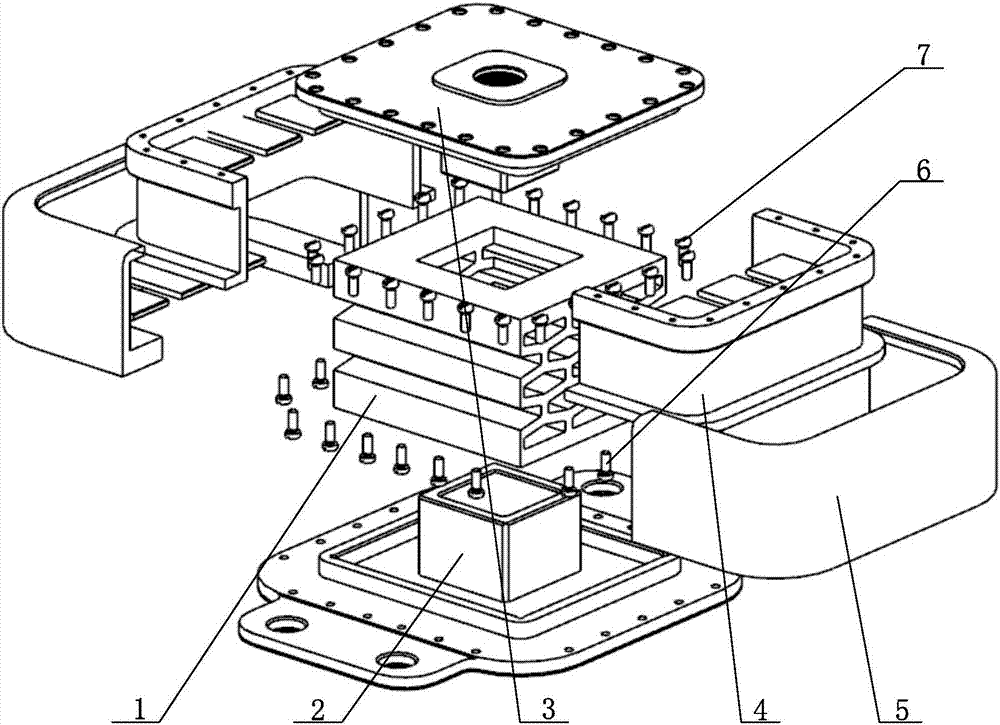

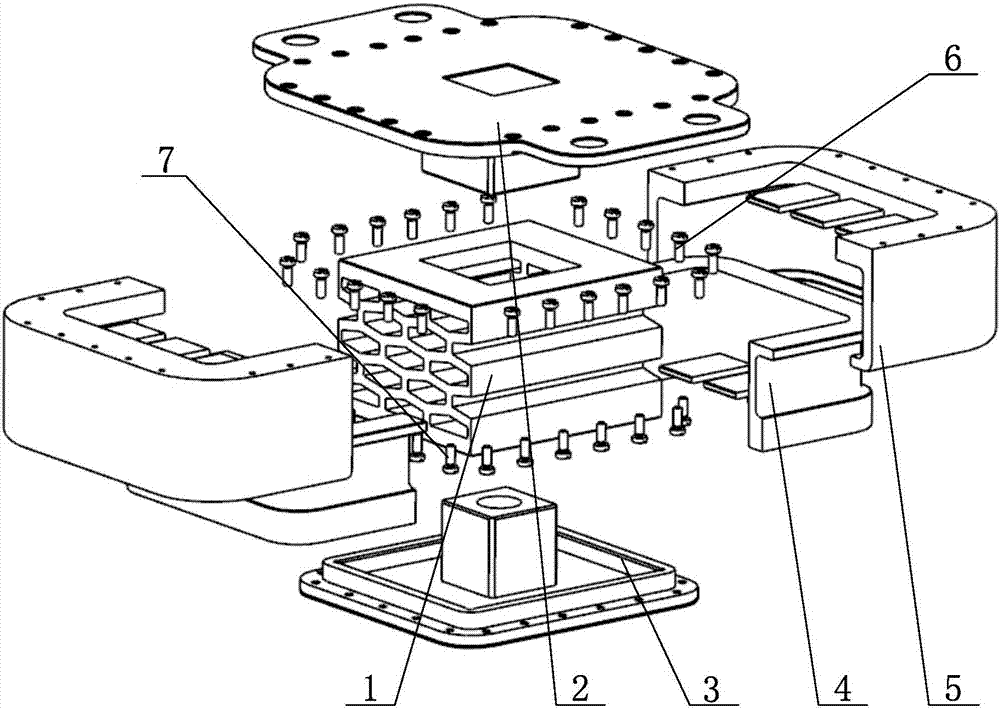

[0030] Referring to the accompanying drawings, an ultra-low-frequency impact-resistant metamaterial vibration isolation device includes: a metamaterial vibration isolation part 1, a lower positioning cover 2, an upper positioning cover 3, an inner limit housing 4, an outer limit housing 5, Lower bolt group 6, upper bolt group 7;

[0031] Metamaterial vibration isolator 1 is obtained by stretching a porous planar structure formed by a finite number of two-dimensional unit cell structures arranged in a periodic order along its normal direction, and the first and last row structures near the upper and lower surfaces are all unit cells Half of the structure; the shape of the metamaterial vibration isolator 1 two-dimensional unit cell structure is a hexagon with 4 hypotenuses and 2 vertical sides;

[0032] The left and right ends of the lower positioning cover 2 are provided with mounting holes, and the middle position of the upper surface is provided with a "back" shaped boss groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com