A modified inorganic fireproof glue

A fireproof glue, inorganic technology, applied in the field of materials, can solve problems such as toxicity and poor waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

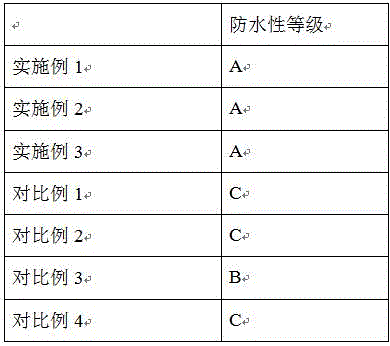

Examples

Embodiment 1

[0014] The present embodiment adopts non-toxic, harmless inorganic materials, including the following raw materials in weight percentage: 55% sodium silicate, 30% silicon dioxide, 5% aluminum phosphate and 10% magnesium silicate, wherein the particle size of silicon dioxide is between 1-5μm, the purity is greater than 98%; first add sodium silicate, silicon dioxide and magnesium silicate into the enamel reaction kettle, fully react and highly polymerize the inorganic polymer binder formed, and then add aluminum phosphate to cure and modify , to obtain the fireproof glue of the present invention.

Embodiment 2

[0016] This embodiment adopts non-toxic, harmless inorganic materials, including the following raw materials in weight percentage: 45% sodium silicate, 30% silicon dioxide, 15% aluminum phosphate and 10% magnesium silicate, wherein the particle size of silicon dioxide is between 1-3μm, the purity is greater than 95%; first add sodium silicate, silicon dioxide and magnesium silicate into the enamel reaction kettle, fully react and highly polymerize the inorganic polymer binder formed, and then add aluminum phosphate to cure and modify , to obtain the fireproof glue of the present invention.

Embodiment 3

[0018] This embodiment adopts non-toxic, harmless inorganic materials, including the following raw materials in weight percentage: 45% sodium silicate, 30% silicon dioxide, 15% aluminum phosphate and 10% potassium silicate, wherein the particle size of silicon dioxide is between 1-3μm, the purity is greater than 95%; first add sodium silicate, silicon dioxide and magnesium silicate into the enamel reaction kettle, fully react and highly polymerize the inorganic polymer binder formed, and then add aluminum phosphate to cure and modify , to obtain the fireproof glue of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com