Advanced process control method of wet etching process

A wet etching and etching technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve problems such as inability to reduce film thickness changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

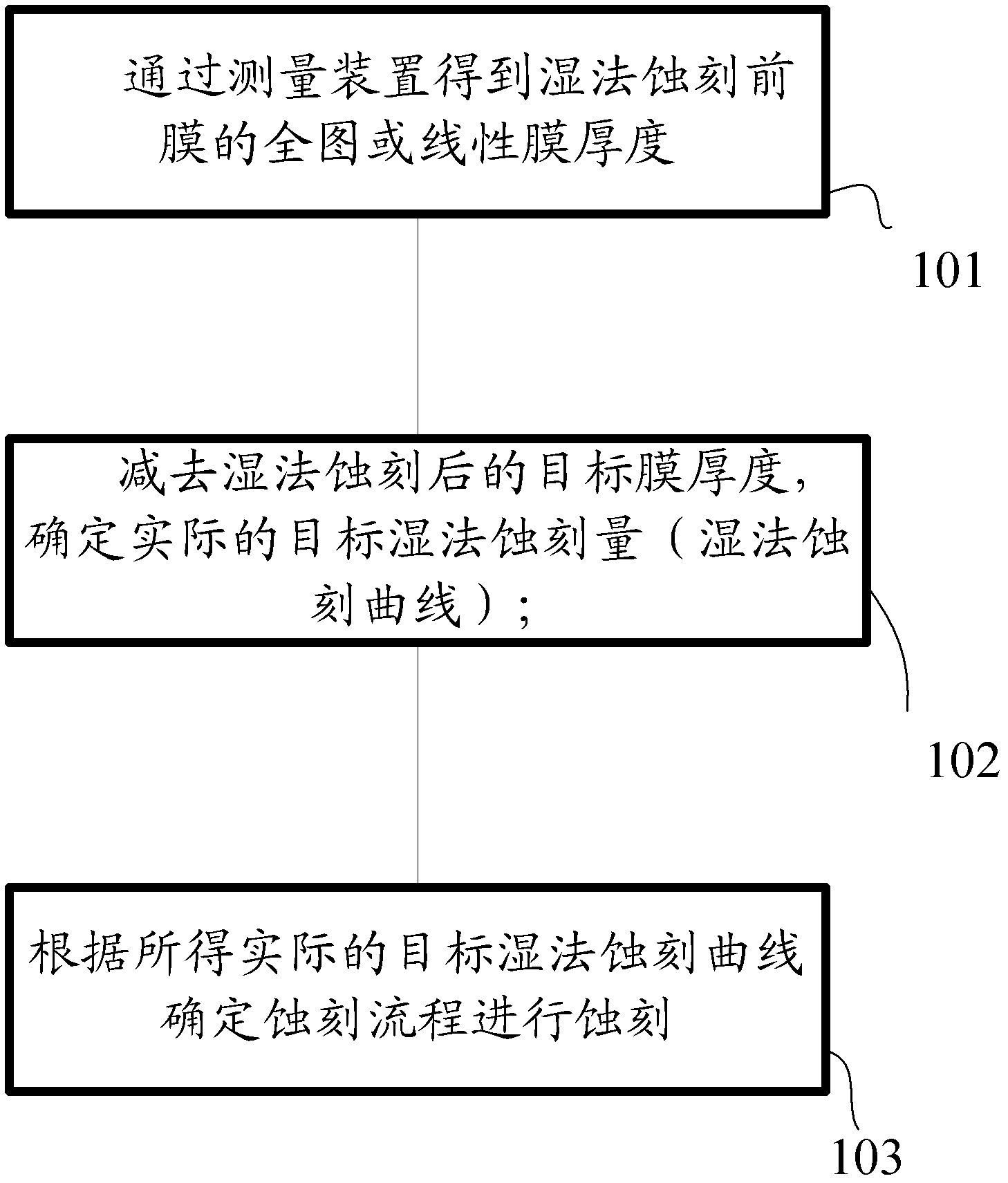

[0049] to be removed using a conventional wet etch process film to get The target film thickness for such a process as an example.

[0050] The target film thickness obtained by conventional methods is The wafer is placed on the workbench.

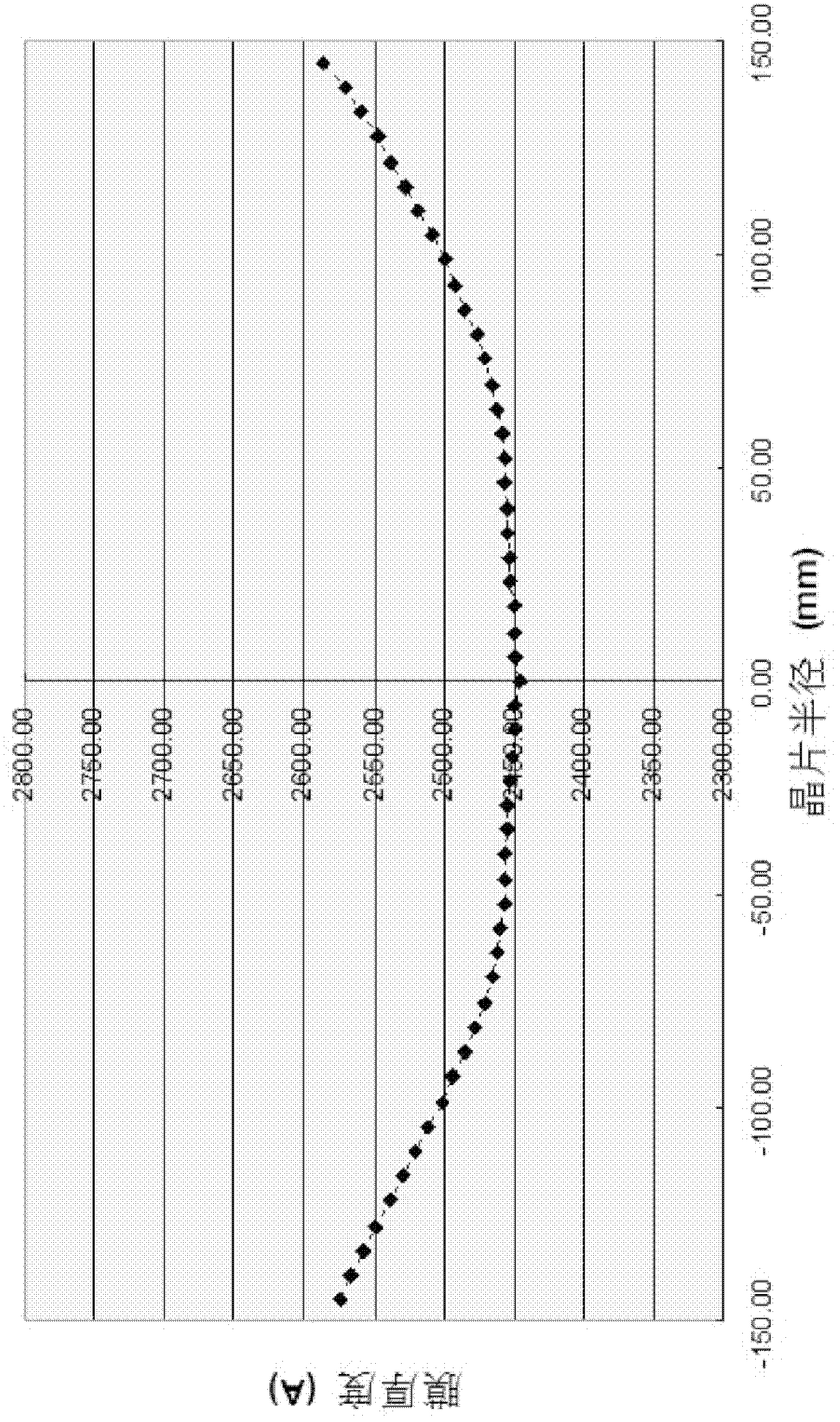

[0051] Utilize the Aleris model machine platform of KLA-Tencor Company to measure the linear film thickness of the film before wet etching, as figure 2 shown.

[0052] The resulting data is transmitted to a controller which can be interfaced with a computer for processing, displaying and / or storing the data. The computer compares the full image or linear film thickness of the input film with the target film thickness after wet etching, determines the actual target wet etching curve, and outputs the parameters of the etching process to the controller. When the value obtained by subtracting the target film thickness after wet etching from the full image or linear film thickness of the film before wet etching is less than 0, the output...

Embodiment 2

[0059] Utilize and the target film thickness of the same batch of embodiment 1 is wafers for experiments. The wet etching process was carried out in the same manner as in Example 1, except that the advanced process control method of Example 1 was not implemented, but the conventional etching process was directly performed (the etching time was fixed at 270s).

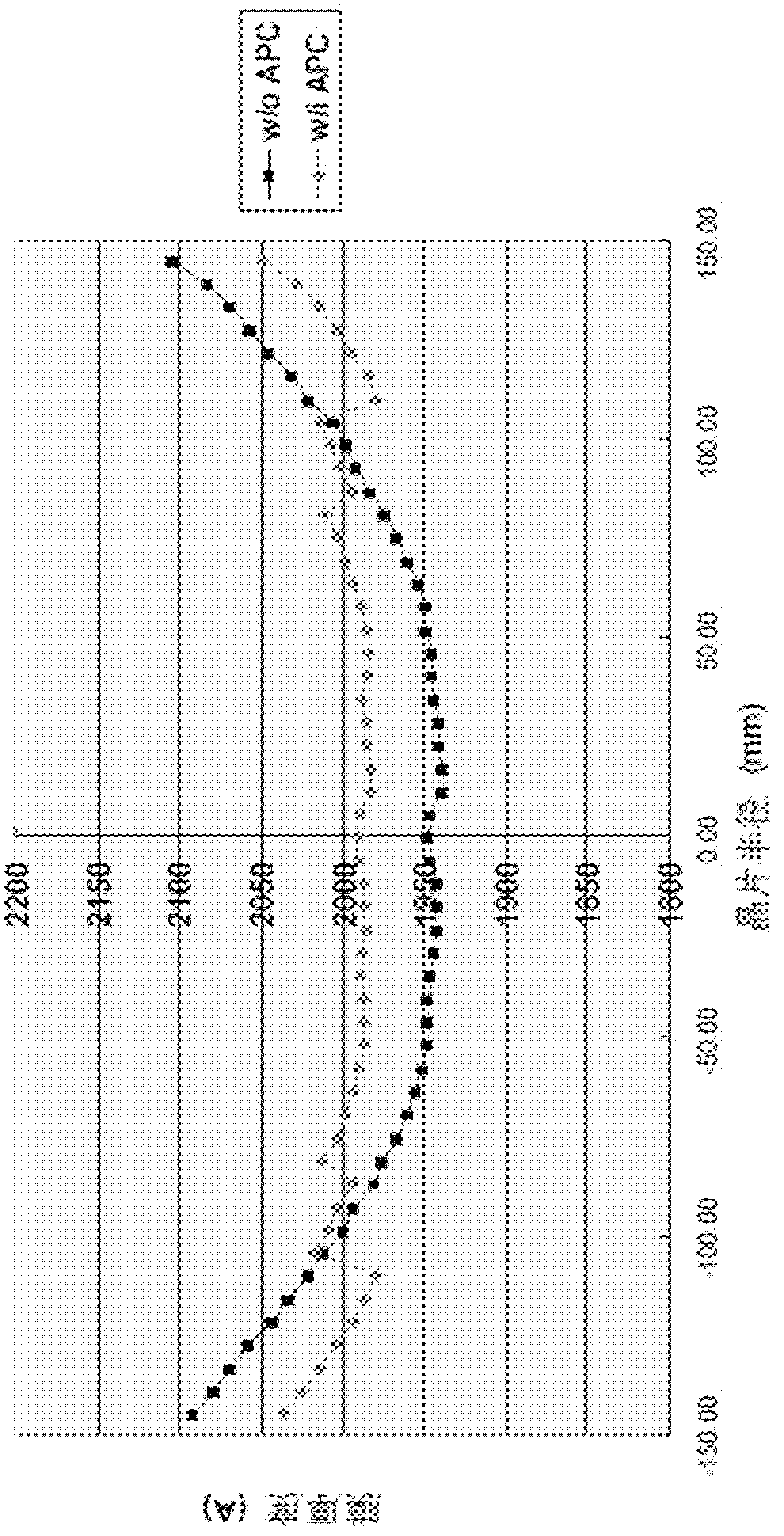

[0060] Utilize the Aleris model machine platform of KLA-Tencor Company to measure the linear film thickness of the film after wet etching, as image 3 Middle curve w / o APC is shown.

[0061] Table 1

[0062]

[0063] Table 1 shows the linear film thickness under different conditions, it can be seen that before etching, the actual value of the average film thickness is lower than the target value by about where the difference between the maximum value (wafer edge) and the minimum value (wafer center) is The standard deviation (STD) of the film thickness was 41.97, and the in-chip inhomogeneity % (U%) was 2.83, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com