Processing method of nano bacterial cellulose superfine fiber yarn

A technology of bacterial cellulose and superfine fiber, which is applied in the direction of fiber treatment, yarn, and complete sets of equipment for producing artificial threads, etc., can solve the problems that the bacterial cellulose fiber yarn production method of bacterial cellulose fiber yarn has not been found and other problems, and achieves The effect of enhancing overall competitiveness, simple production method, and high production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

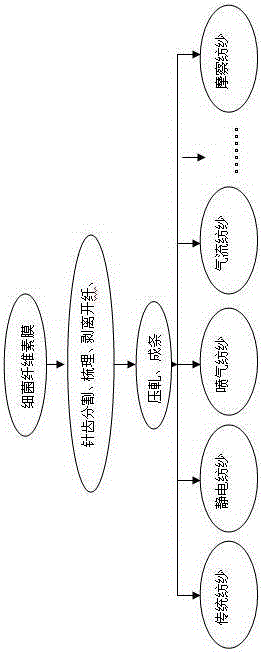

Image

Examples

Embodiment 1

[0022] The bacterial cellulose wet film is held and fed by a holding roller with a diameter of 25 mm. Under the action of a licker-in roller with a diameter of 300 mm, a rotating speed of 400 rpm, a length of 10 mm, and a density of 10 needles / cm2, the bacterial cellulose wet film is The bacterial cellulose wet film was carded and segmented to obtain ultrafine bacterial cellulose fibers with a fiber diameter of 450 nm and a length of 5-100 mm. In order to facilitate the requirements of the next process, the fibers on the licker-in roller are peeled off by the fiber stripping device of the air nozzle, and the fibers are pressed into strips by the fiber pressing device, and the bacterial cellulose fiber strips after the strips are directly introduced into the diameter of 400mm. inside the coiler. When the coil barrel is full, the coil barrel is directly sent to the spinning process, and the nano bacterial cellulose superfine fiber yarn is spun by the traditional ring spinning pr...

Embodiment 2

[0024] The bacterial cellulose wet film is held and fed by a holding roller with a diameter of 25 mm. Under the action of a licker-in roller with a diameter of 300 mm, a rotating speed of 400 rpm, a length of 10 mm, and a density of 10 needles / cm2, the bacterial cellulose wet film is The bacterial cellulose wet film was carded and segmented to obtain ultrafine bacterial cellulose fibers with a fiber diameter of 400nm and a length of 5-100mm. In order to facilitate the requirements of the next process, the fibers on the licker-in roller are peeled off by the fiber stripping device of the air nozzle, and the fibers are pressed into strips by the fiber pressing device, and the bacterial cellulose fiber strips after the strips are directly introduced into the diameter of 400mm. inside the coiler. When the cans are full, they are sent directly to the spinning process. On the air spinning machine into nano bacterial cellulose superfine fiber yarn.

Embodiment 3

[0026] The bacterial cellulose wet film is held and fed by a holding roller with a diameter of 25 mm. Under the action of a licker-in roller with a diameter of 300 mm, a rotating speed of 400 rpm, a length of 10 mm, and a density of 10 needles / cm2, the bacterial cellulose wet film is The bacterial cellulose wet film was carded and segmented to obtain ultrafine bacterial cellulose fibers with a fiber diameter of 400nm and a length of 5-100mm. In order to facilitate the requirements of the next process, the fibers on the licker-in roller are peeled off by the fiber stripping device of the air nozzle, and the fibers are pressed into strips by the fiber pressing device, and the bacterial cellulose fiber strips after the strips are directly introduced into the diameter of 400mm. inside the coiler. When the cans are full, they are sent directly to the spinning process. Nano bacterial cellulose superfine fiber yarn is spun by wool spinning mule spinning process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com