A kind of fiber concrete material and preparation method thereof for 3D printing

A technology of fiber concrete and 3D printing, applied in the direction of additive processing, etc., can solve the problems of limited structural types, rapid construction design and increased technical obstacles, etc., to achieve strong integrity, change the failure form of bending resistance, and excellent cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

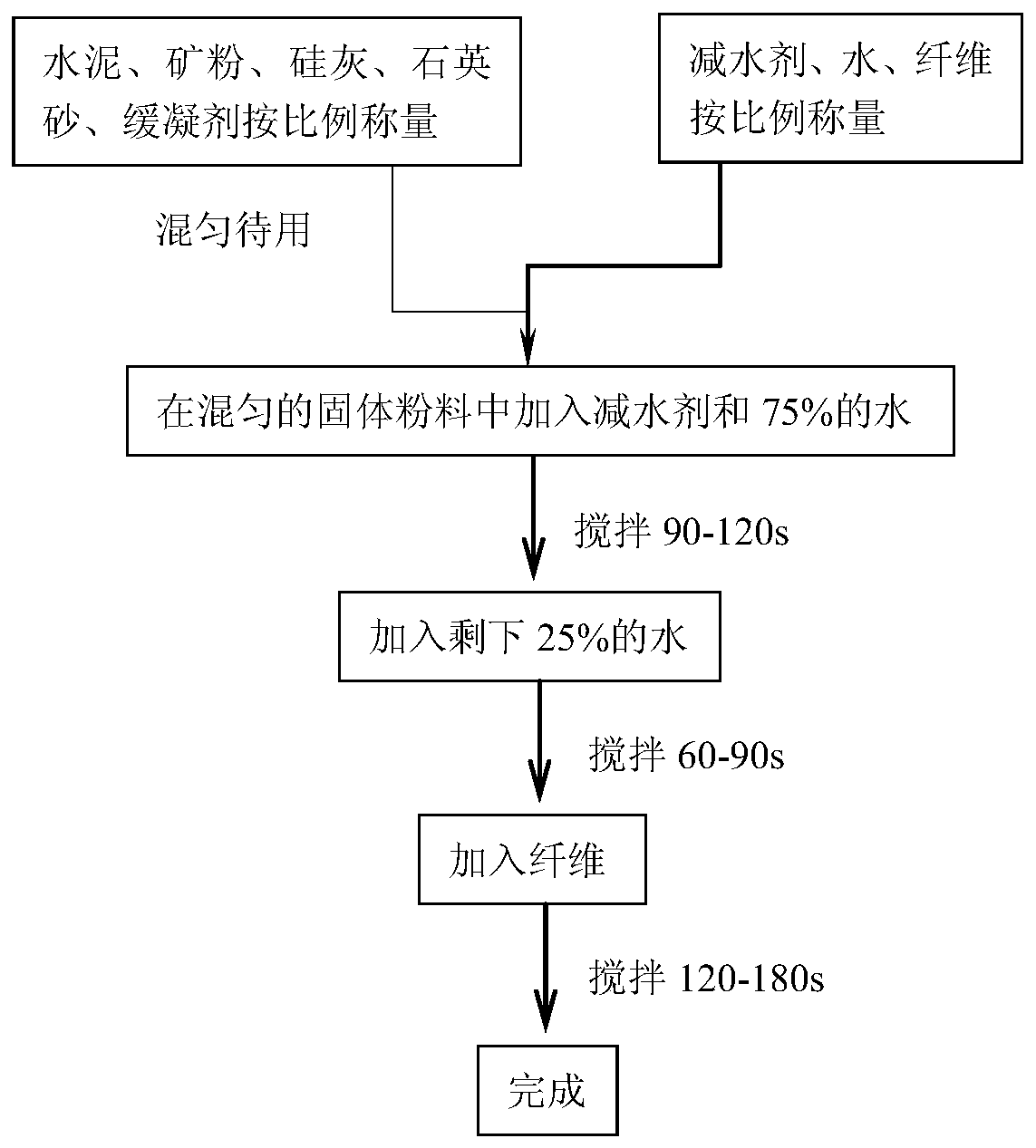

[0081] The preparation method for the fiber concrete material that the present invention provides for 3D printing comprises the following steps:

[0082] (1) After weighing cement, mineral powder, silica fume, quartz sand and setting retarder in proportion, mix them to obtain solid powder for use;

[0083] (2) Weigh the water reducing agent, water and fiber in proportion before use;

[0084] (3) Add water reducer and 3 / 4 of water to the mixed solid powder, stir for 90-120s, then add the remaining 1 / 4 of water, stir for 60-90s to obtain the mixture;

[0085] (4) Add fibers into the mixture obtained in step (3), and stir for 120-180s to obtain the fiber concrete material.

[0086] Refer to the standard "Measurement Method for Fluidity of Cement Mortar Sand" (GB_T2419-2005) to test the fluidity of fiber concrete materials, and "Standards for Test Methods of Basic Properties of Building Mortar" (JGJ / T70-2009) to test the initial setting time and final temperature of fiber concret...

Embodiment 1

[0090] In parts by weight, weigh 8.1 parts of sulfoaluminate cement, 6.5 parts of mineral powder, 1.6 parts of silica fume, 4.9 parts of quartz sand, 2.6 parts of water, 0.34 parts of polycarboxylate superplasticizer, and 0.0081 parts of tartaric acid retarder , 0.16 parts of fiber.

[0091] The specific construction method is to weigh cement, mineral powder, silica fume, quartz sand, and setting retarder in proportion, and then mix them to obtain solid powder for use. Weigh the water reducing agent, water and fiber in proportion before use. Add water reducer and 3 / 4 water to the mixed solid powder, stir for 90-120s, then add the remaining 1 / 4 water, stir for 60-90s. The fibers are added to the mixture obtained in the previous step and stirred for 120-180s to obtain the concrete.

[0092] The performance test results of the prepared fiber concrete material are: the fluidity is 158mm; the initial setting time is 27min, the final setting time is 47min; the 1-day compressive st...

Embodiment 2

[0095] In parts by weight, weigh 8.4 parts of sulfoaluminate cement, 6.7 parts of mineral powder, 1.7 parts of silica fume, 5.0 parts of quartz sand, 2.35 parts of mixing water, 0.39 parts of polycarboxylate superplasticizer, tartaric acid retarder 0.0084 parts, fiber 0.1 parts.

[0096] Concrete construction method is with embodiment 1.

[0097] The performance test results of the prepared fiber concrete material are: the fluidity is 158mm; the initial setting time is 28min, the final setting time is 45min; the 1-day compressive strength is 43.52MPa, the 3-day compressive strength is 60.57MPa, and the 7-day compressive strength is 73.85MPa. The 28-day compressive strength is 85.61MPa; the 1-day flexural strength is 8.02MPa, the 3-day flexural strength is 10.76MPa, the 7-day flexural strength is 12.97MPa, and the 28-day flexural strength is 12.90MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com