Flexible electrode based on polyvinyl alcohol and preparation method of flexible electrode

A polyvinyl alcohol and flexible electrode technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve problems such as poor hydrophilicity, unsuitable stretching, and limited improvement of electrode capacity, so as to achieve safety in the production process, Effects with low production cost and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Put 1 g of polyvinyl alcohol, acetylene black and polyaniline into 10 mL of water after being ground and heated to 95°C while stirring, then heat-preserve and ultrasonically treat for 20 minutes to obtain a uniform slurry; the polyvinyl alcohol, acetylene black and polyaniline The mass ratio of aniline is 45:45:10;

[0040] (2) Add 60 μL of glutaraldehyde to the slurry, stir evenly, pour it into a glass petri dish with a diameter of 7 cm, heat it with a heating plate at 30°C to evaporate the water, and obtain a film;

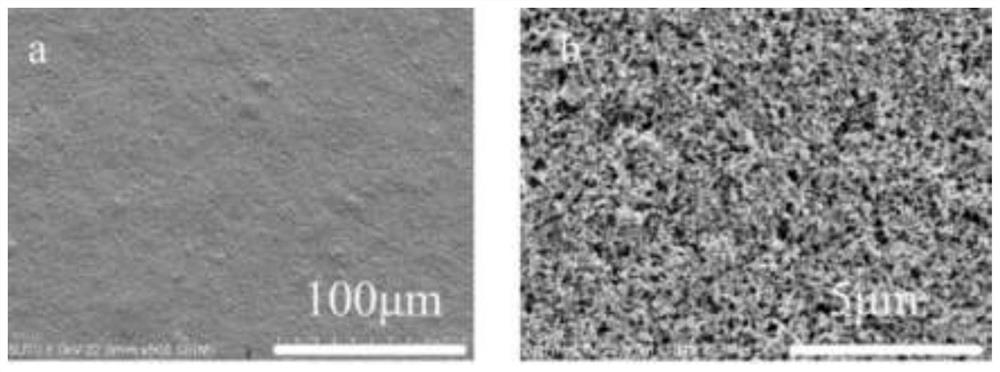

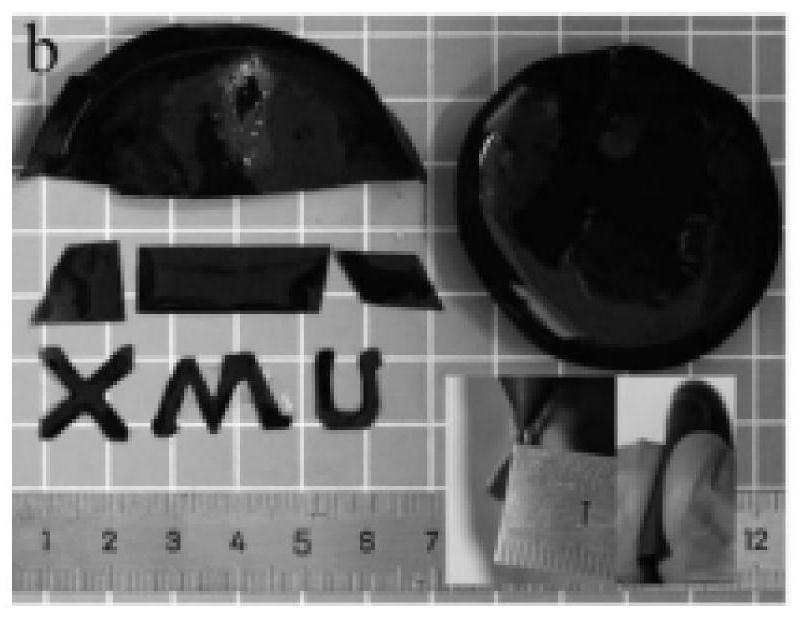

[0041] (3) Soak the film obtained in step (2) in 10mL of 1M hydrochloric acid solution for 10min, then fully wash with water, and then properly cut to obtain such figure 1 The flexible electrodes shown, can then embed conductive carbon fibers in them to obtain elastic hydrogel electrodes, and as figure 2 As shown, the flexible electrode can be cut into various shapes and can be easily folded.

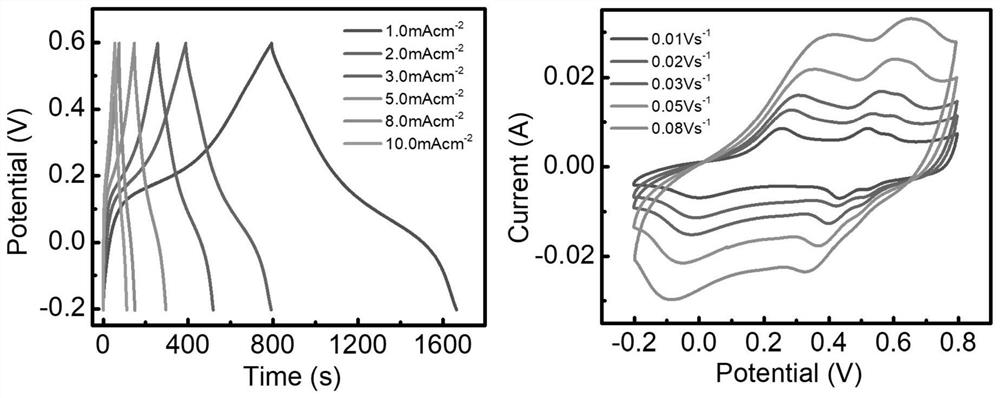

[0042] The conductivity of the flexible electrode prep...

Embodiment 2

[0045] (1) Grinding 0.1 g of polyvinyl alcohol, acetylene black, carbon nanotubes and nano-manganese dioxide powder, placed in 1.0 mL of water and heated to 95 ° C while stirring, and then heat-preserved and ultrasonically treated for 20 minutes to obtain a slurry; The mass ratio of polyvinyl alcohol, acetylene black, carbon nanotubes and nano manganese dioxide powder is 60:30:5:5;

[0046](2) Add 10 μL of glutaraldehyde to the slurry, stir evenly, pour it into 4 continuous electrode-shaped stainless steel tanks, insert several carbon fiber threads into the quick-drying material, and wait for the water to evaporate naturally;

[0047] (3) Soak the material obtained in step (2) in 10 mL of 1M sulfuric acid solution for 5 min, then fully wash with water, and then cut it appropriately to obtain an elastic hydrogel electrode made of the flexible electrode, as shown in Figure 4 As shown, the elastic hydrogel electrode can be folded multiple times.

[0048] The conductivity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com