Nano bacterial cellulose superfine fiber processing equipment

A bacterial cellulose and microfiber technology, which is applied in fiber processing, complete sets of equipment for producing artificial threads, textiles and papermaking, etc., can solve the problems of single structure, no simplicity, convenience, and low added value of products, and achieve application fields. Wide range, high efficiency, clean processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

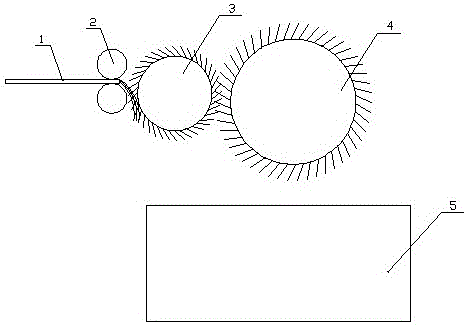

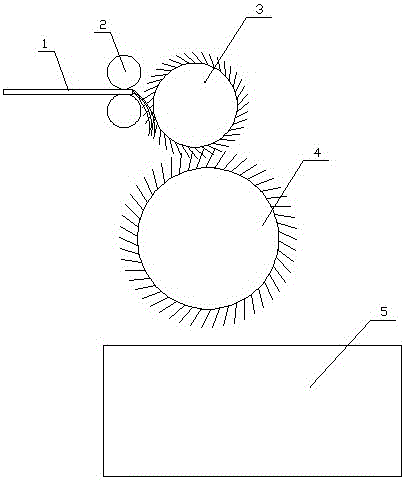

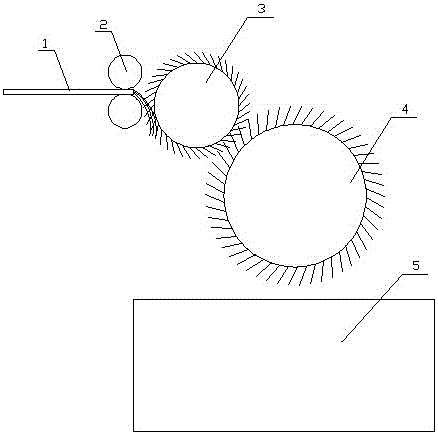

[0020] The invented processing equipment for the physical refinement of nano-bacterial cellulose superfine fibers includes a pair of rollers 2 holding the wet film of bacterial cellulose, a licker-in roller 3 is arranged at the rear of the rollers, and a fiber roller is arranged on one side of the licker-in roller. The stripping device 4 is provided with a coiling device 5 at the rear part of the stripping device 4 .

[0021] The licker-in roller includes a central shaft, on which a cylinder is sheathed, and the outer wall of the cylinder is provided with needle-like carding acupuncture. The diameter of the cylinder is 200-600 mm, the length of the acupuncture is 0.1-5 cm, and the diameter of the acupuncture rod is 0.001-5 cm. 3mm, the diameter of the needle tip is 1~100um, the length of the needle tip is 1~10mm, the needle density is 2~1000 / cm 2 .

[0022] The fiber stripping device includes a central shaft, on which a drum is set, and the outer wall of the drum is provided ...

Embodiment 2

[0024] Such as figure 1 As shown, a licker-in roller 3 with a diameter of 300 mm is installed behind a pair of holding rollers 2 with a diameter of 30 mm, and a peeling roller with a diameter of 200 mm is installed directly behind the licker-in roller 3 . The bacterial cellulose fiber web after the bacterial cellulose film 1 is peeled off is sent to the coiling device 5 to be packaged in a barrel with a diameter of 800 mm after being rolled by a sliver roll. The needle length on the surface of the licker-in roller is 3cm, the diameter of the needle shaft is 1mm, the diameter of the needle tip is 10um, the length of the needle tip is 10mm, and the needle density is 20 pieces / cm 2 . The needle length on the surface of the peeling roller is 3cm, the diameter of the needle rod is 3mm, the diameter of the needle tip is 50um, the length of the needle tip is 5mm, and the needle density is 15 pcs / cm 2 .

Embodiment 3

[0026] Such as figure 2 As shown, a licker-in roller with a diameter of 200mm is installed at the rear of a pair of holding rollers with a diameter of 30mm, and a peeling roller with a diameter of 600mm is installed directly below the licker-in roller. The stripped bacterial cellulose fiber web is rolled by a sliver roll and then sent to a coiling device to be packaged in a drum with a diameter of 800mm. Among them, the length of needling on the surface of the licker-in roller is 0.1cm, the diameter of the needling shaft is 0.001mm, the diameter of the needling tip is 1um, the length of the needling tip is 1mm, and the needling density is 1000 pieces / cm 2 . The needle length on the surface of the peeling roller is 0.1cm, the diameter of the needle rod is 0.001mm, the diameter of the needle tip is 1um, the length of the needle tip is 1mm, and the needle density is 1000 pieces / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com