Follow-up forecast method for milling deformation of complex integral structural components

A technology of overall structural parts and prediction methods, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effects of reducing production costs, utilizing and improving, and shortening trial production and production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by way of examples.

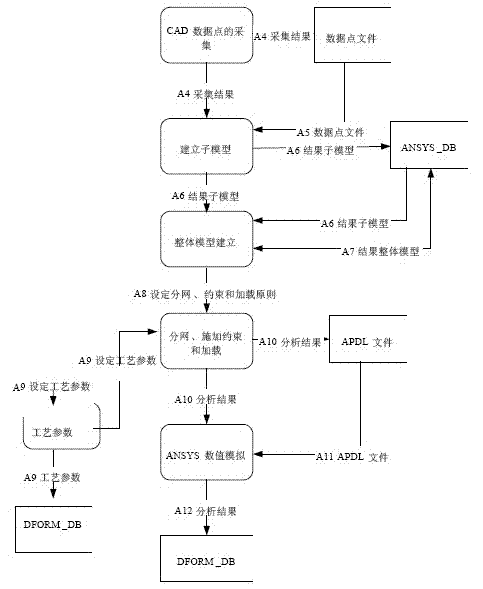

[0021] Such as figure 1 The follow-up prediction method for the milling deformation of complex integral structural parts shown mainly includes the following steps:

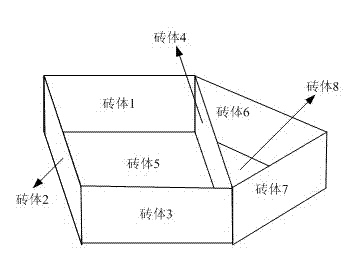

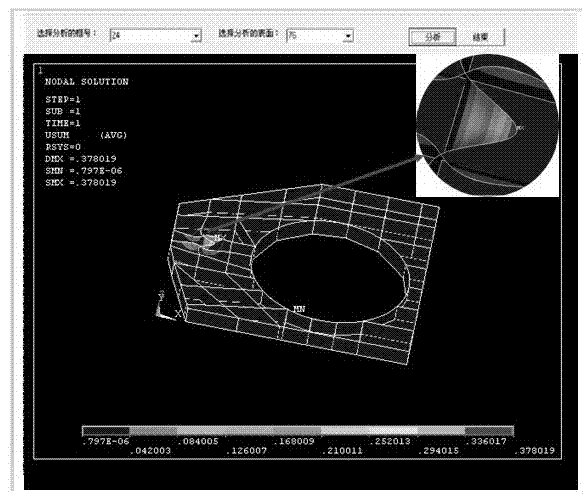

[0022] The first step is to realize the modeling and analysis of complex overall structural parts, such as figure 2 As shown, computer simulation of processing is carried out, which includes the following steps:

[0023] a. First, the collection of CAD model data points will be carried out from the data point file;

[0024] b. According to the collection results or data point files in a, realize the establishment of the CAD processing sub-model, and store the established sub-model in the finite element background database ANSYS_DB:

[0025] c. According to the results of b, complete the establishment of the CAD processing overall model, and store the established overall model in the finite element background database ANSYS_DB; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com