Component

A technology for parts and main parts, applied in the direction of contact parts, etc., can solve the problems of easy and fast corrosion, loss, expensive precious metals, etc., and achieve the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

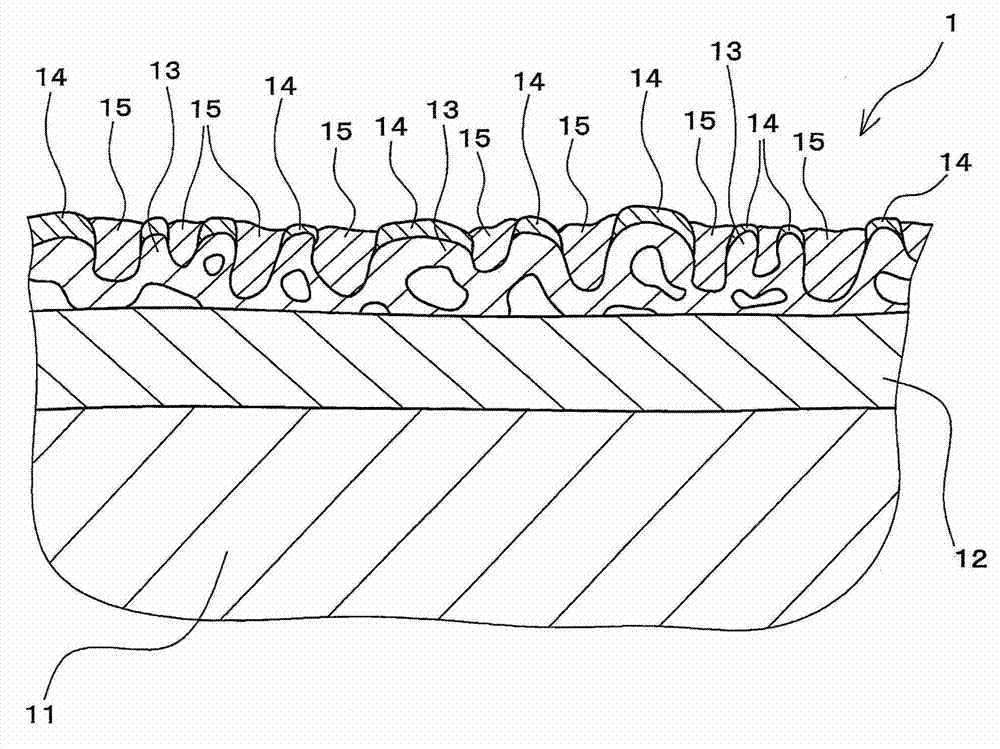

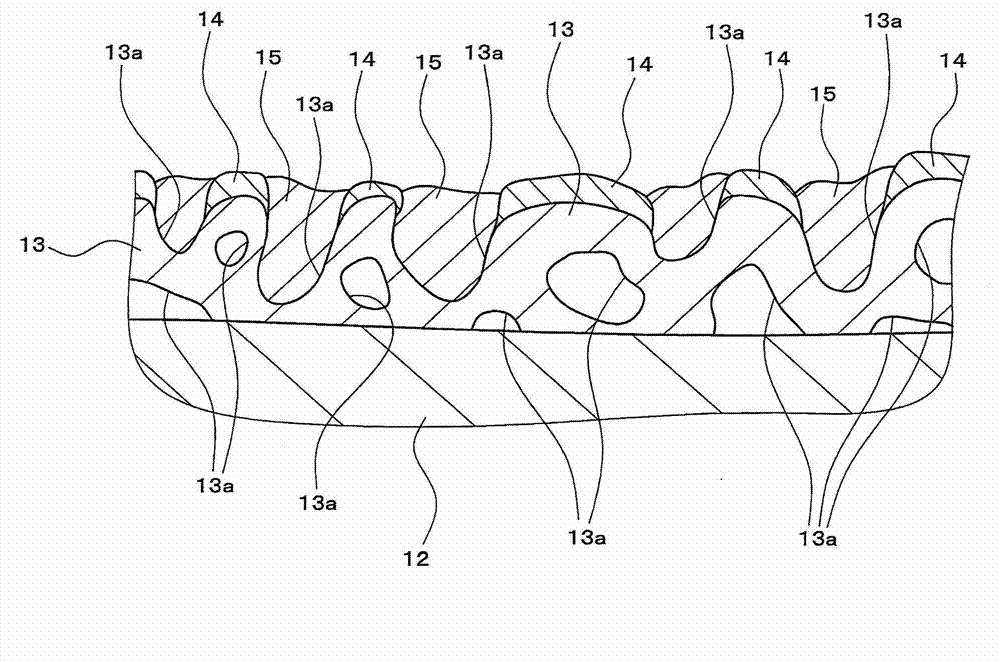

[0045] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In the description of this embodiment, the case where the present invention is applied to an electronic component constituting a terminal for a connector is taken as an example, but the present invention is not limited to this example, and the present invention can also be applied to other cases other than this example. invention. The present invention can be widely applied to components having a main body formed of a metal material and having a plated layer formed on the surface. That is, the present invention can be applied to electronic components other than terminals, and the present invention can also be applied to metal components other than electronic components.

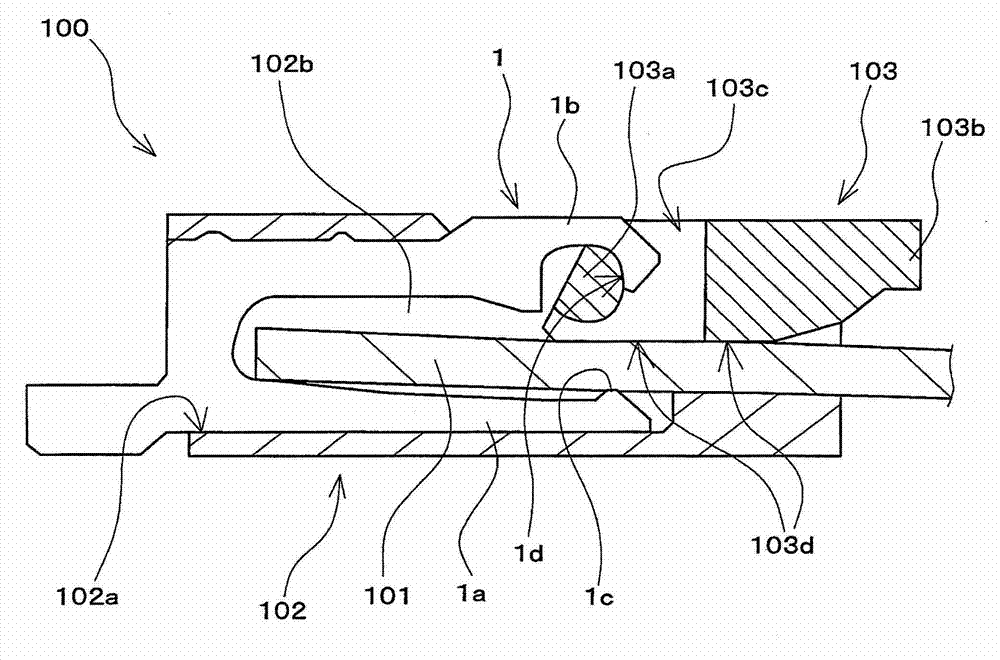

[0046] figure 1 It is a cross-sectional view showing a state where the connector terminal 1 configured as a component in the present embodiment is attached to the connector 100 . The connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com