Method and special device for generating atmospheric pressure DC glow discharge

A DC glow discharge, atmospheric pressure technology, applied in electrical components, plasma and other directions, can solve problems such as small discharge gaps, achieve stable performance, stable operating costs, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

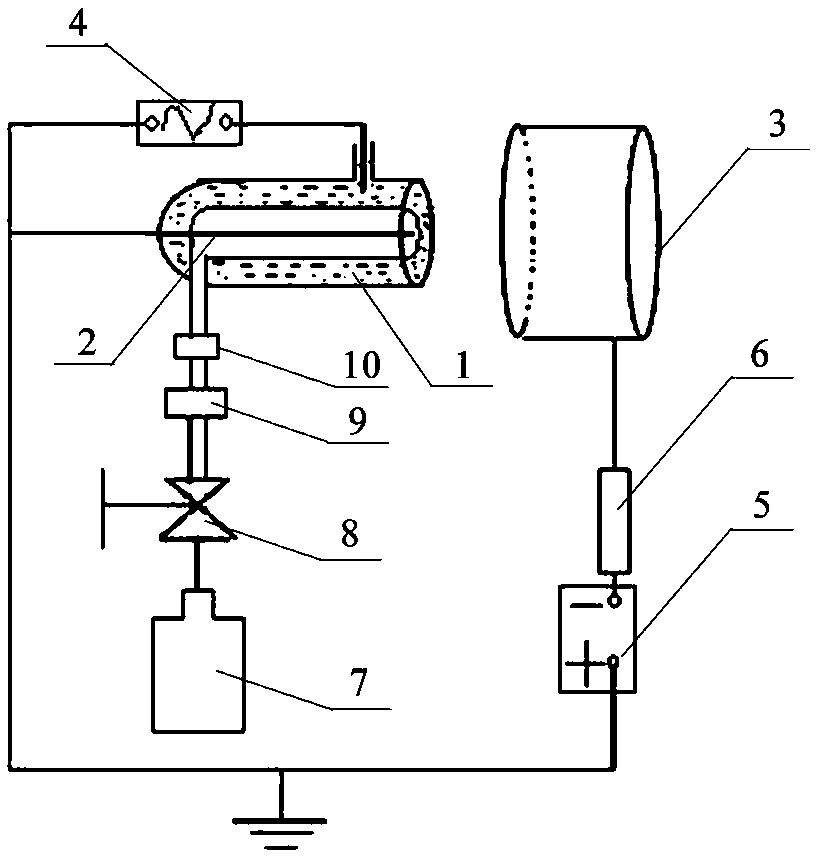

[0025] Such as figure 1 As shown, the DC glow discharge device of the present invention includes a coaxial dielectric tube 1, a metal rod electrode 2, a flat plate electrode 3, a gas supply system and a high voltage power supply. Among them, the dielectric barrier discharge system is composed of the coaxial dielectric tube 1 and the metal rod electrode 2, and the glow discharge system is composed of the flat plate electrode 3 and the metal rod electrode 2.

[0026] Wherein, the coaxial medium pipe 1 is a double-layer tubular airtight container body with an axial central cavity and a U-shaped cross-section. The airtight container body is filled with a conductive liquid (the conductive liquid may be water), and the airtight container body There is an air inlet leading to the central cavity on the side wall, which is used for filling the gas supply system with working gas. The inner diameter of the coaxial medium pipe 1 can be set according to the flow rate of the gas to be intr...

Embodiment 2

[0034] The method for generating atmospheric pressure DC glow discharge in the present invention is as follows: a coaxial dielectric tube 1 with a double-layer tubular airtight container body with an axial center cavity and a U-shaped cross-section is provided, and the airtight container body is filled with conductive liquid. An air inlet leading to the central inner chamber is opened on the side wall of the container body.

[0035] A metal rod electrode 2 is set, and the metal rod electrode 2 is inserted into the central cavity of the coaxial dielectric tube 1 from the sealing end of the coaxial dielectric tube 1, and the rear end of the metal rod electrode 2 is grounded, and the front end is set on the coaxial dielectric tube 1. The open end of the central lumen of tube 1.

[0036] A plate electrode 3 is arranged outside the open end of the coaxial dielectric tube 1 .

[0037] Connect the air supply system to the air inlet.

[0038] Connect one end electrode of the AC high v...

Embodiment 3

[0041] The DC glow discharge device of the present invention can also be completed in another way: one end of the metal rod electrode is grounded, and a plate electrode electrically connected to the DC high-voltage power supply is arranged on the outside of the other end of the metal rod electrode; The upper part is wrapped with an insulating medium such as a ceramic plate, and an aluminum sheet or other conductive medium connected to an AC high-voltage power supply is arranged on the outside of the insulating medium. In this way, an AC high-voltage dielectric barrier discharge system is composed of aluminum sheets, ceramic plates and metal rod electrodes, and a DC high-voltage glow discharge system is formed through the flat plate electrodes and the above-mentioned metal rod electrodes to realize the generation of The active particles and ultraviolet photoionization ignite the DC discharge channel between the metal rod electrode and the plate electrode, thereby producing a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com