Vacuum processing apparatus

A vacuum processing device and vacuum processing chamber technology, applied in vacuum evaporation plating, ion implantation plating, coating, etc., can solve problems such as unfavorable production efficiency and cost increase, and achieve improved maintainability, easy installation, and reduced effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

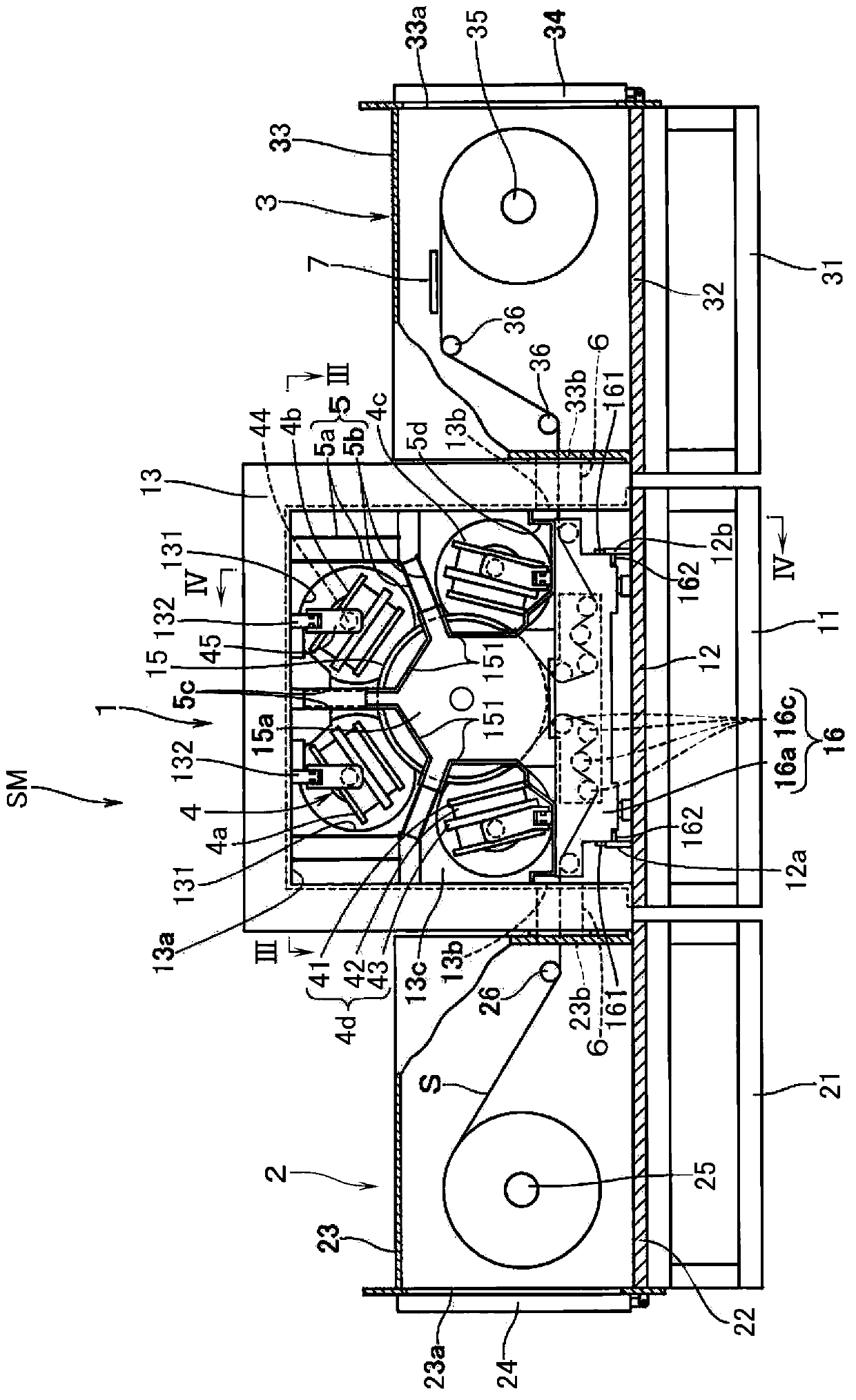

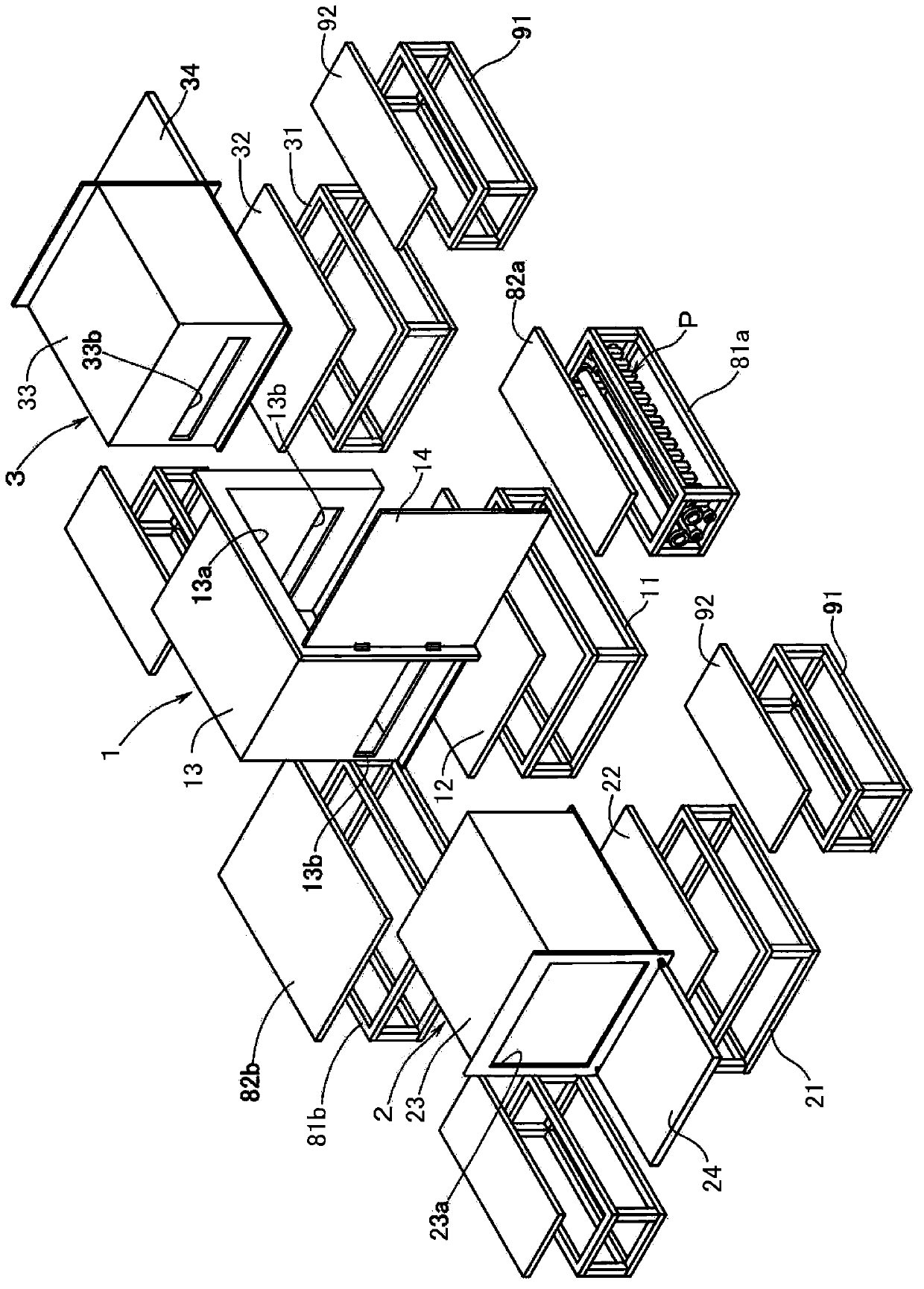

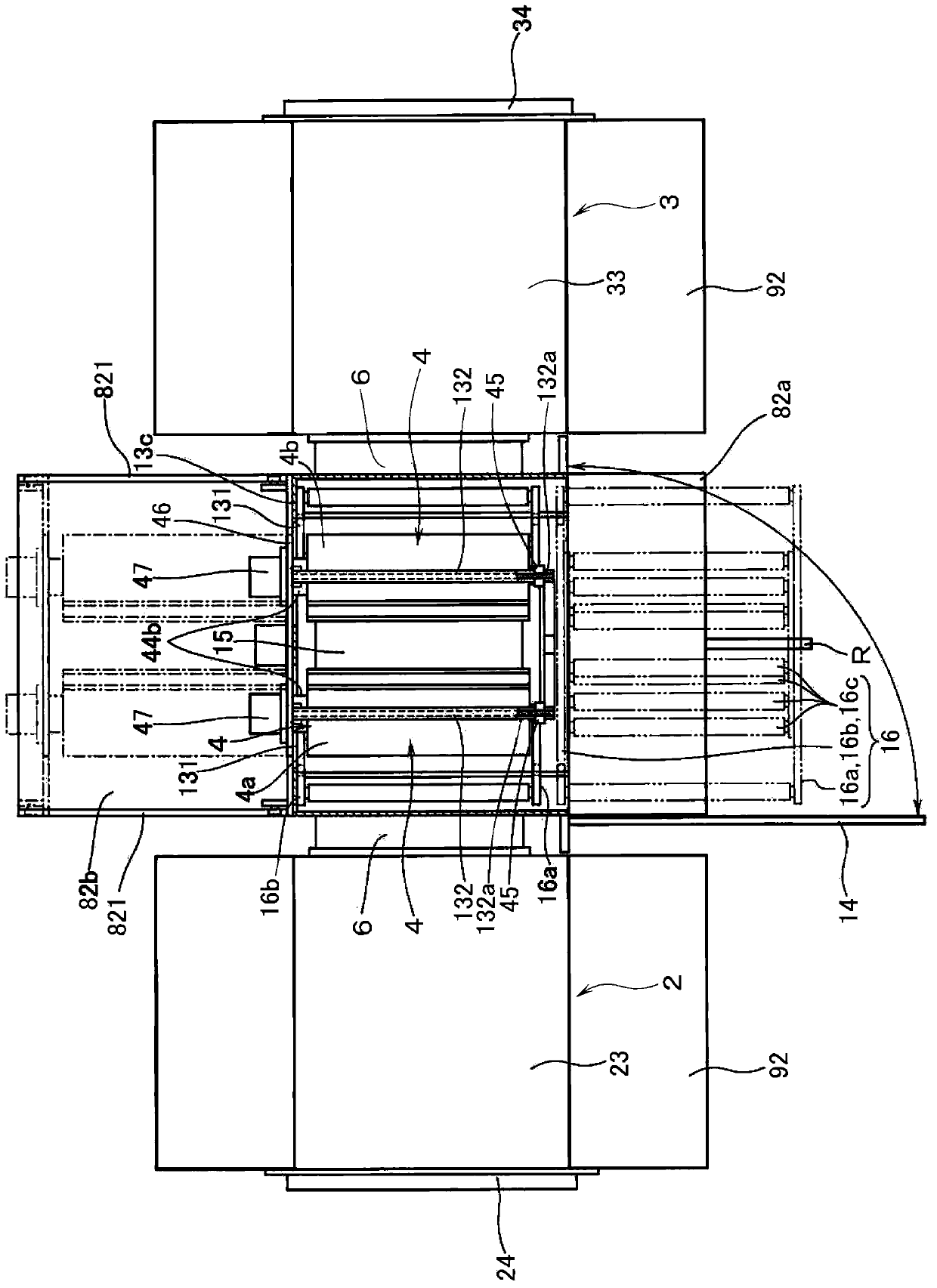

[0025] Hereinafter, referring to the drawings, the vacuum processing apparatus of this embodiment will be described by taking a case where a multilayer film is formed on one surface of a sheet-shaped substrate S using a cathode unit for sputtering film formation as a processing unit as an example. As the sheet-shaped base material S, a resin material or the like that differs depending on the application can be used.

[0026] refer to Figure 1 to Figure 4 , SM is the vacuum processing device of this embodiment. The vacuum processing apparatus SM has, for example, a central vacuum processing chamber 1 evacuated by a vacuum pump (not shown) such as a cryopump, and the upstream side of the vacuum processing chamber 1 ( figure 1 The vacuum auxiliary chamber 2 that is connected to the left side of the figure) and evacuated by a vacuum pump not shown, and the downstream side of the vacuum processing chamber 1 ( figure 1 Another vacuum auxiliary chamber 3 connected to each other an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com