Catalyst for dephosphorizing yellow phosphorus tail gas and preparation method thereof

A yellow phosphorus tail gas, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as increasing equipment and operational complexity, chemical changes in active centers, and deactivation of active centers. , to achieve the effect of prolonging the service life, low preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

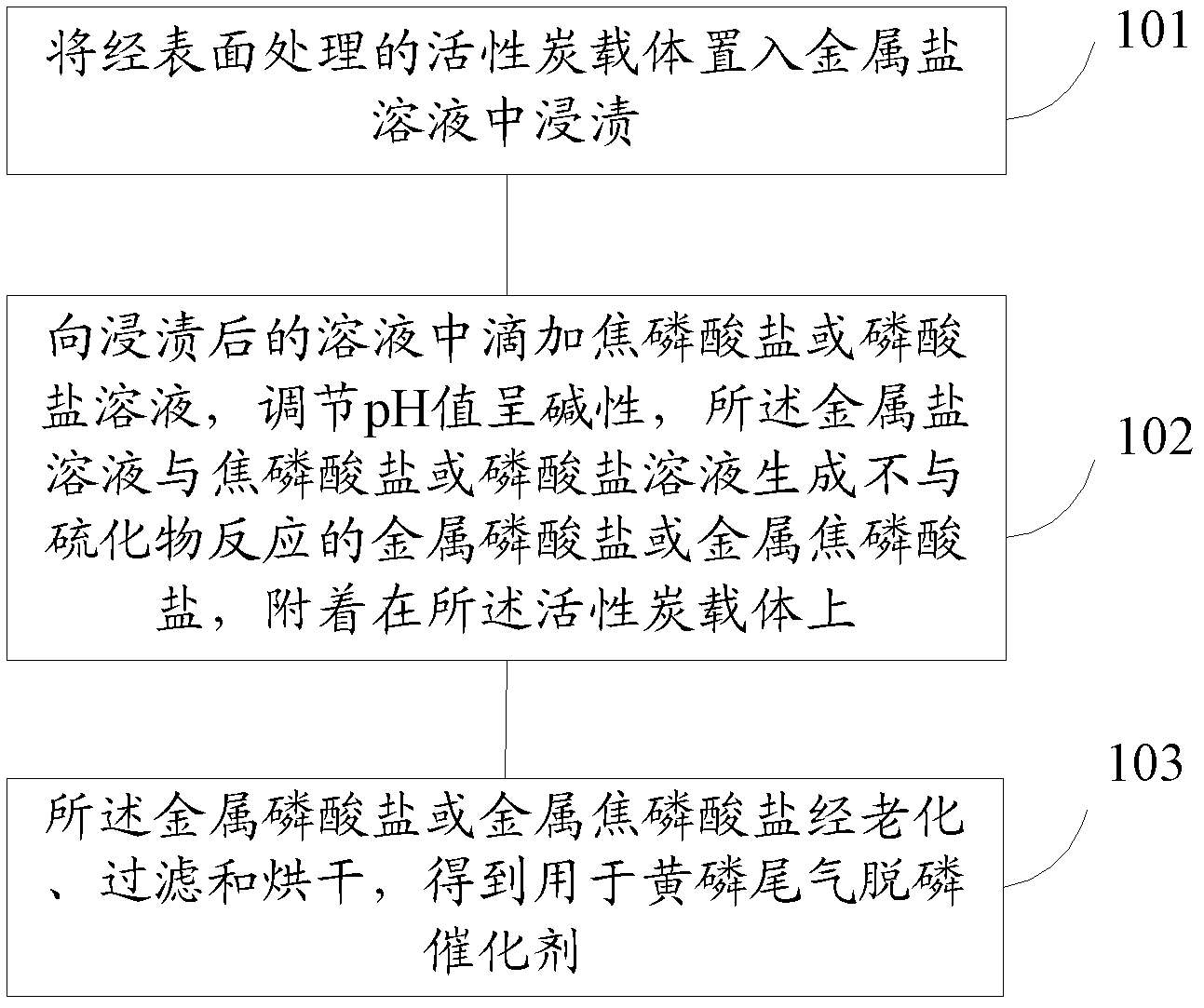

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] For the prior art, when the yellow phosphorus tail gas is dephosphorized by catalytic reaction, the catalytic product is attached to the catalyst, so that the catalyst needs to be regenerated after a period of use. Changes, resulting in catalyst deactivation, these reasons make the catalytic reaction can not continue.

[0035] In view of this, the inventors of this patent have creatively proposed one of the core ideas of the embodiments of the present invention, which is to propose a metal phosphate or metal pyrophosphate that does not react with sulfide as the catalytic active component, so that the surface treated The catalyst with active carbon as the catalyst carrier is used for the dephosphorization reaction of yellow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com