Combination machining method of front half body of riding type motorcycle frame and auxiliary device thereof

A riding motorcycle and combined processing technology, which is applied in the direction of auxiliary equipment, motorcycles, auxiliary welding equipment, etc., can solve the installation position error of the engine installation hole position and shock absorber, affect the installation quality, and the installation accuracy of the engine and shock absorber Reduce and other problems, achieve the effect of improving installation quality, ensuring installation accuracy, and improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

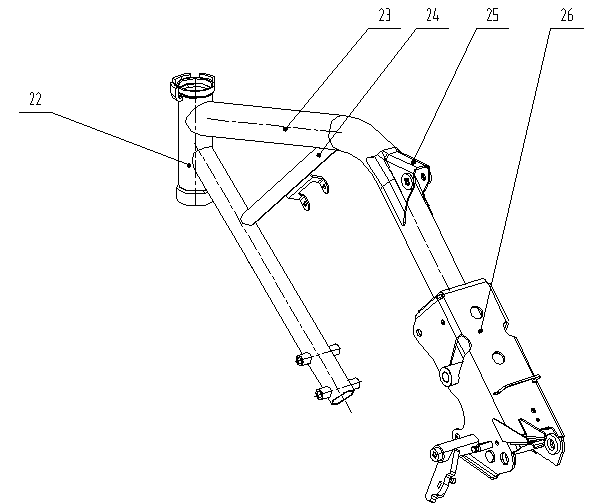

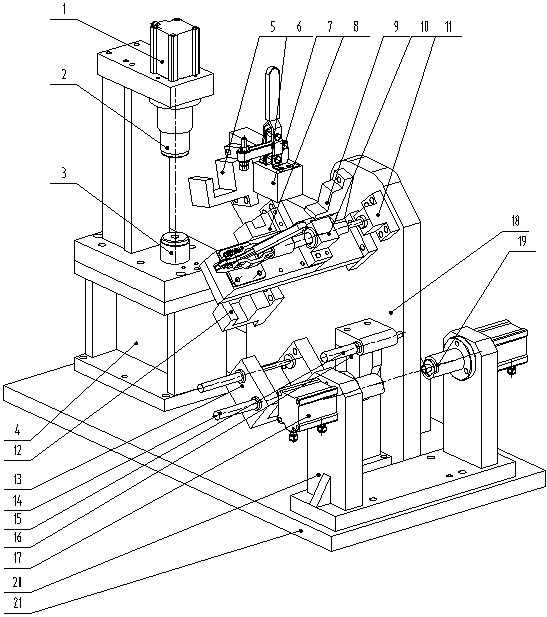

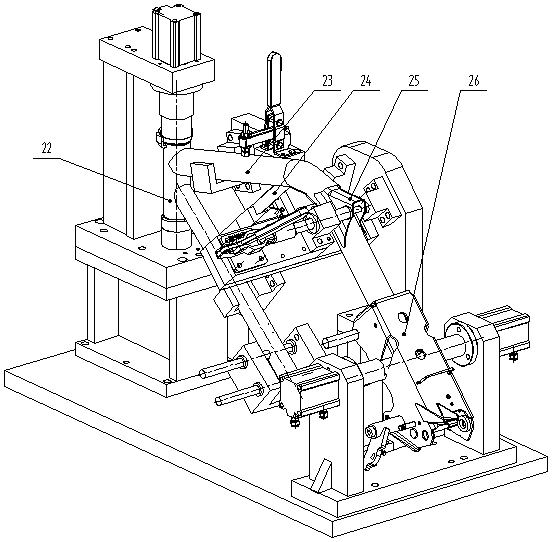

[0031] Such as Figure 2-3 As shown, the auxiliary device disclosed in this specific embodiment is a combined processing auxiliary device for the front half of the motorcycle frame, including a base plate 21, a combined positioning mechanism for the head tube assembly and a main positioning mechanism arranged on the base plate 21. , connecting pipe positioning mechanism, shock absorbing box positioning mechanism and engine main suspension combined positioning mechanism; the head tube assembly combined positioning mechanism, supervisory positioning mechanism, connecting pipe positioning mechanism, shock absorbing box positioning mechanism and engine main suspension combined positioning mechanism Used to realize the fixing of the head tube assembly 22, the main pipe 23, the connecting pipe 24, the shock absorber 25 and the engine main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com