Plastic composite body and manufacturing method thereof

A manufacturing method and composite technology, which are applied in chemical instruments and methods, thin material processing, synthetic resin layered products, etc., can solve the problems of broken inserts, large scour force, and increased internal stress of plastic composites, and reduce the Internal stress, the effect of reducing the scour force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

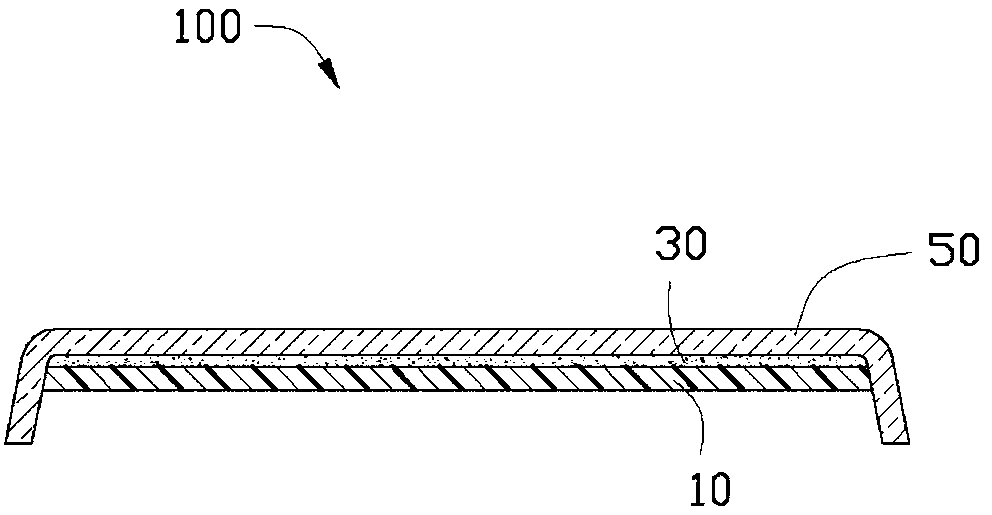

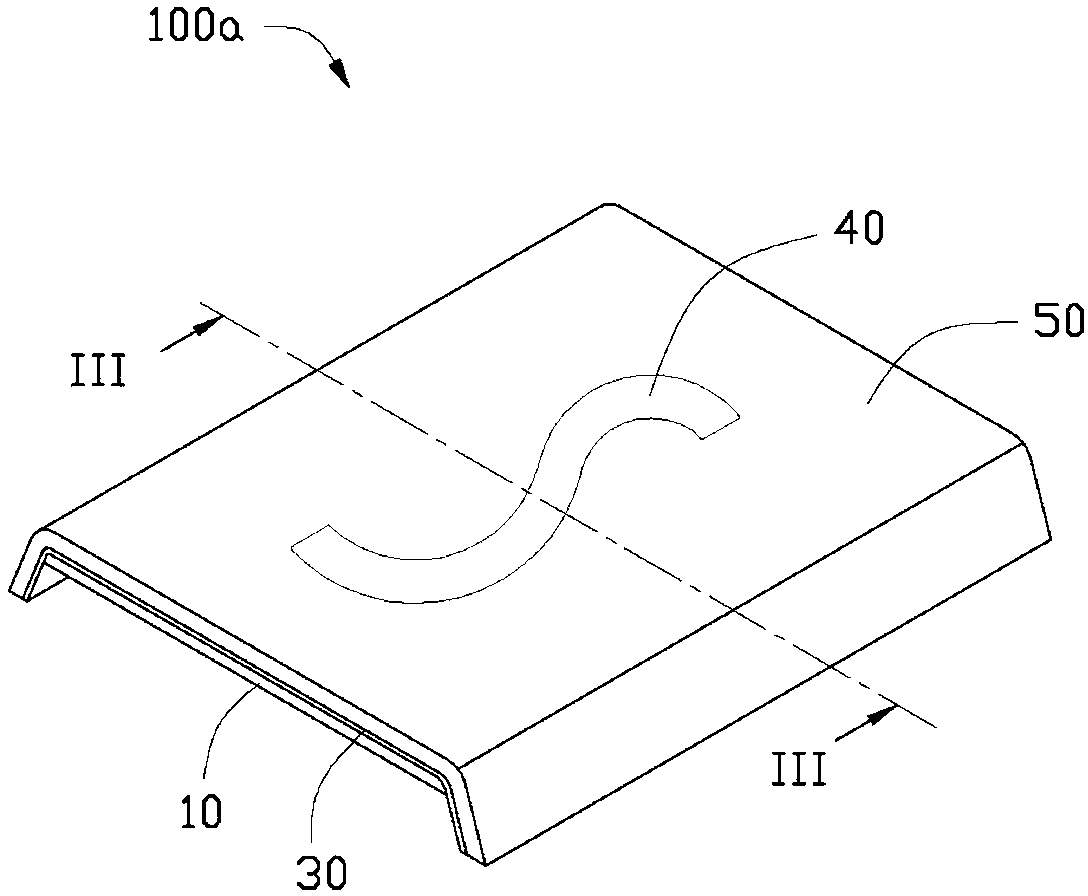

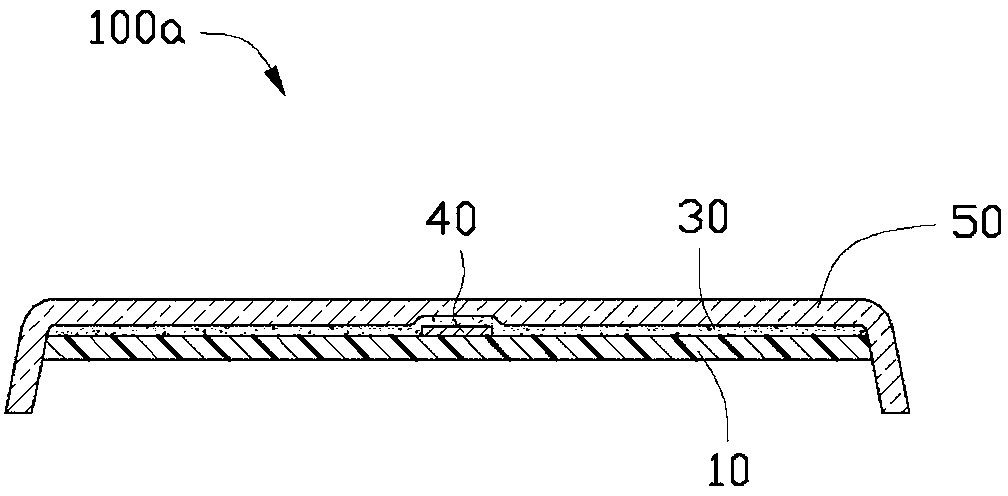

[0022] see figure 1 , The plastic composite 100 of a preferred embodiment of the present invention includes a first plastic part 10 , an adhesive layer 30 and a second plastic part 50 sequentially formed on the first plastic part 10 .

[0023] The material of the first plastic part 10 can be polycarbonate (PC), polymethyl methacrylate (PMMA), a blend of polycarbonate (PC) and polyethylene terephthalate (PET) Any of thermoplastic resins such as polyamide (PA), acrylonitrile-styrene-butadiene copolymer resin (ABS) and polyurethane (PU). Preferably, glass fibers are added to the thermoplastic resin. The thickness of the first plastic part 10 is 0.6-1mm.

[0024] The adhesive layer 30 is colorless and transparent, and is formed on the first plastic part 10 by spraying. The adhesive layer 30 is mainly composed of aminosilane coupling agent. In this example, the main component of the aminosilane coupling agent is γ-aminopropyltriethoxysilane.

[0025] The second plastic part 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com