Scouring-resistant special high-pressure ceramic valve

A high-pressure ceramic and erosion-resistant technology, which is applied in the field of high-pressure ceramic valves, can solve problems such as prolonging the construction period, leakage of internal substances, and damage to the inner core of ceramic valves, and achieves the effects of weakening the erosion force, reducing wear, and making it easy to rotate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

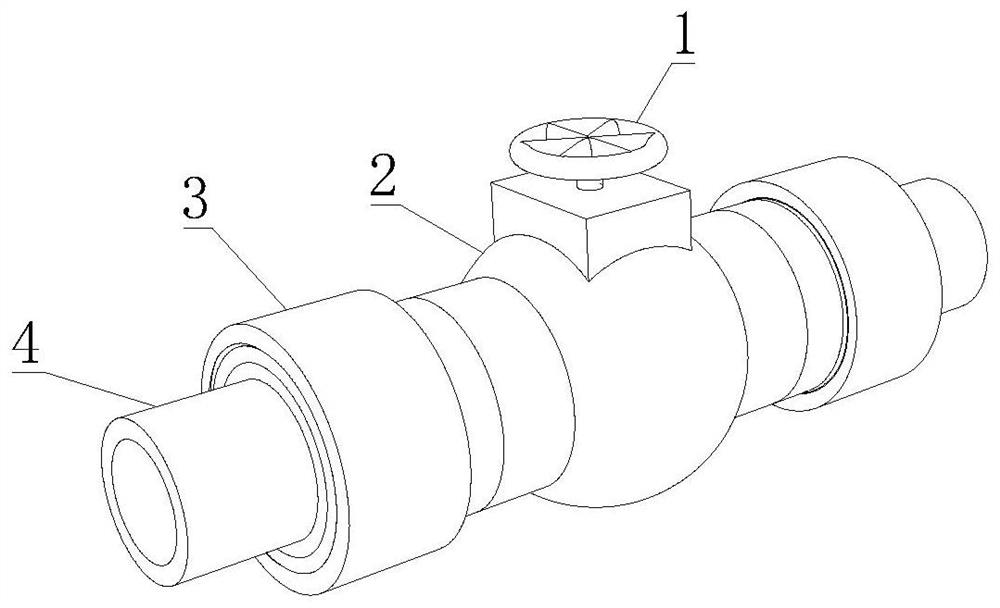

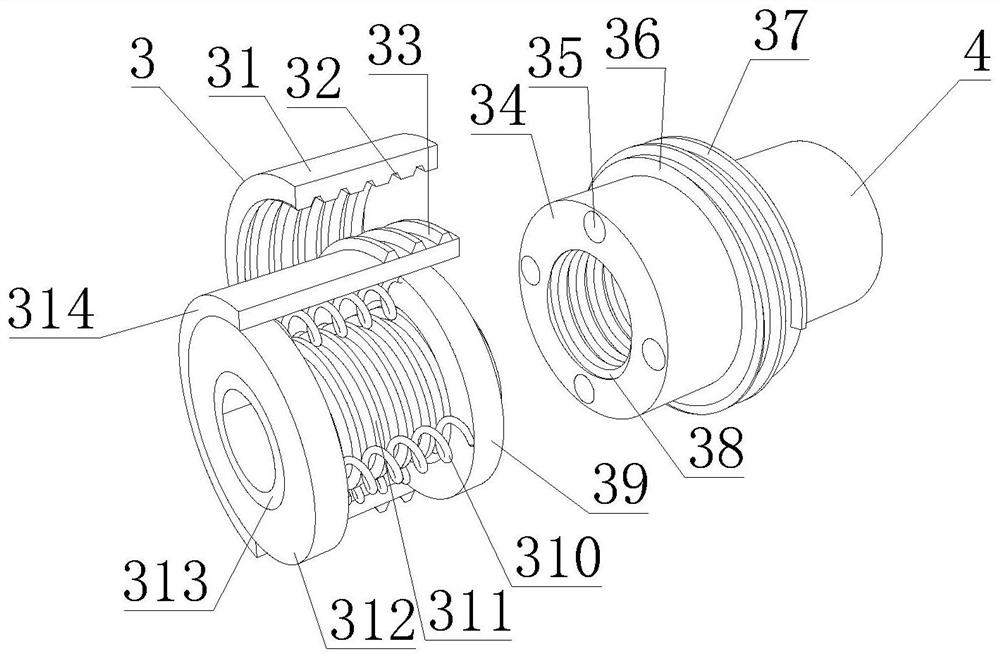

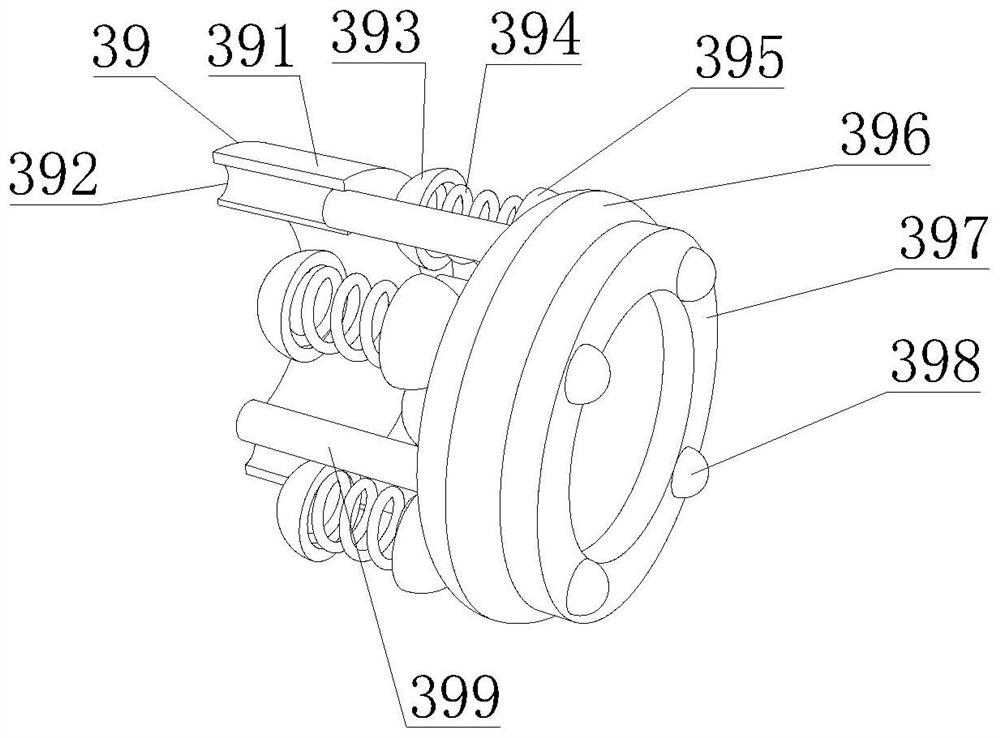

[0035] like Figure 1-6 As shown, the present invention provides a special high-pressure ceramic valve that is resistant to scouring, including a turntable 1, the lower end of the turntable 1 is fixedly connected with a scouring-resistant mechanism 2, and the scouring-resistant mechanism 2 includes a gradient ring 23 and a scouring wheel mechanism 26. The scouring wheel The mechanism 26 includes a wheel mechanism 261, and the wheel mechanism 261 includes a copper plate 2611. The outer side of the copper plate 2611 is provided with a guide groove 2613. One side of the erosion-resistant mechanism 2 is fixedly connected with a connecting mechanism 3, and the connecting mechanism 3 includes a sealing ring. The mechanism 39 and the inner tube 313. The sealing ring mechanism 39 includes a hard rubber ring 391. A circular hole 392 is opened inside the hard rubber ring 391. The outer surface of the inner tube 313 is fixedly connected with a threaded ring 311. An outer tube 4 is fixedl...

Embodiment 2

[0038] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer side of the copper sheet 2611 is fixedly connected with a flow pipe 2612, the inner side of the copper sheet 2611 is fixedly connected with a hexagonal ring 2614, and the copper sheet 2611 is fixedly connected to the inner side. The inner side of the plate 2611 is fixedly connected with an elliptical ring 2615, the outer surface of the elliptical ring 2615 is fixedly connected with the outer surface of the hexagonal ring 2614, one side of the wheel mechanism 261 is fixedly connected with a connecting shaft sleeve 262, and the shaft of the connecting shaft sleeve 262 is fixedly connected. A rotating shaft 263 is fixedly connected to the center of the heart, and reinforcing particles 28 are rotatably connected to both ends of the rotating shaft 263 .

[0039] In this embodiment, through the internal high-speed and high-pressure material impac...

Embodiment 3

[0041] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer side of the scouring wheel mechanism 26 is overlapped with a circular valve core 25, and the inner wall of the circular valve core 25 and the outer side of the reinforcing particles 28 are overlapped. Fixed connection, the inner wall of the circular valve core 25 is fixedly connected with a reinforcing rod 27, the outer side of the circular valve core 25 is rotatably connected with a valve casing 24, the side of the valve casing 24 is fixedly connected with a connecting pipe 21, and the inner wall of the connecting pipe 21 is fixedly connected There is a gradient plate 22, the other end of the gradient plate 22 is fixedly connected with a gradient ring 23, the upper side of the valve shell 24 is fixedly connected with a sealing seat 29, the upper side of the circular valve core 25 is fixedly connected with a connecting column 210, The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com