Modified polyamide composite membrane and preparation method thereof

A composite film, polyamide technology, applied in chemical instruments and methods, flexible coverings, synthetic resin layered products, etc., can solve the problems of increasing the adhesive layer, high production cost, complex structure, etc., and achieve good appearance. , Good compatibility, good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

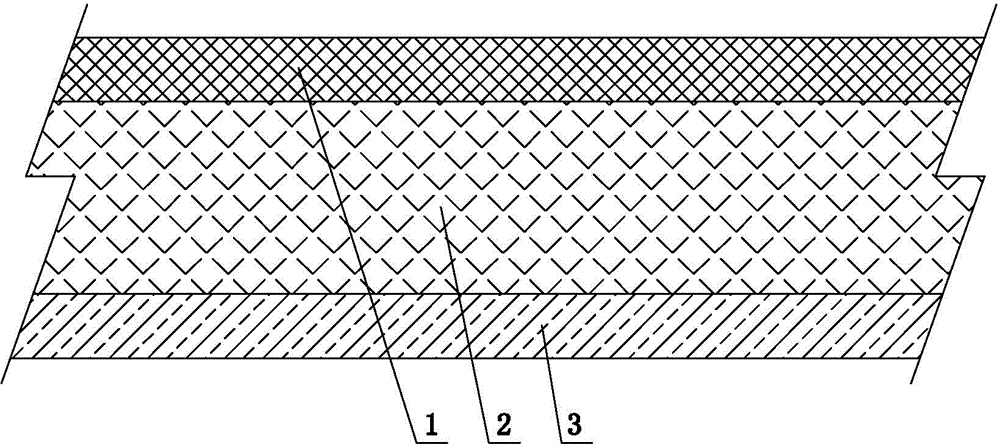

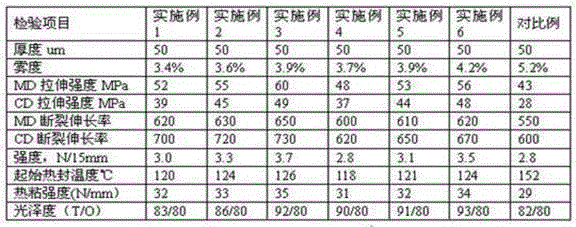

[0023] Example 1: The preparation method of the polyamide composite film: the corona layer material selects 100 parts of polypropylene homopolymer resin with a melting index of 8g / 10min; the core layer selects 100 parts of modified polyamide, 8 parts of polypropylene terpolymer, propylene- 2 parts of hexene copolymer, 0.001 part of erucamide slip agent (made by blending and granulating 95% polypropylene and 5% high-purity erucamide, the same below); the heat-sealing layer is made of terpolymer copolymer 100 parts of resin, 0.001 part of erucamide slip agent, 0.001 part of synthetic wollastonite anti-blocking agent (made by blending and granulating 10% amorphous silica and 90% polypropylene, the same below). The above three layers of materials are melted through their respective single-screw extruders, and then film-formed through a batching block connector, T-shaped die head co-extrusion, casting and cooling. The product is subsequently cooled and shaped, thickness tested, c...

Embodiment 2

[0025] Example 2:The preparation method of the polyamide composite film: the corona layer material selects 100 parts of polypropylene homopolymer resin with a melt index of 8g / 10min; the core layer selects 100 parts of modified polyamide, 24 parts of polypropylene terpolymer, propylene- 6 parts of hexene copolymer, 0.002 part of erucamide slip agent; 100 parts of ternary copolymer polypropylene resin, 0.002 part of erucamide slip agent, and 0.002 part of synthetic wollastonite anti-blocking agent. The above three layers of materials are melted through their respective single-screw extruders, and then film-formed through a batching block connector, T-shaped die head co-extrusion, casting and cooling. The product is subsequently cooled and shaped, thickness tested, corona treated, online slitting, winding and packaging, and finally the finished product is obtained.

[0026] The preparation method of the modified polyamide is as follows: 100 parts of fully dried polyamide, 30 p...

Embodiment 3

[0027] Example 3: The preparation method of the polyamide composite film: the corona layer material selects 100 parts of polypropylene homopolymer resin with a melt index of 8g / 10min; the core layer selects 100 parts of modified polyamide, 40 parts of polypropylene terpolymer, propylene- 10 parts of hexene copolymer (comonomer content greater than 20%, propylene content of 8%), 0.003 parts of erucamide slip agent; 100 parts of terpolymer copolymer resin for heat sealing layer, 0.003 parts of erucamide slip agent parts, 0.003 parts of synthetic wollastonite anti-blocking agent. The above three layers of materials are melted through their respective single-screw extruders, and then film-formed through a batching block connector, T-shaped die head co-extrusion, casting and cooling. The product is subsequently cooled and shaped, thickness tested, corona treated, online slitting, winding and packaging, and finally the finished product is obtained.

[0028] The preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com