Asphalt polymer cement waterproof coating

A waterproof coating and polymer technology, applied in the field of asphalt-based waterproof coatings, can solve the problems of affecting the waterproof function of polymer waterproof coatings, the inability to use waterproof roofs, and short service life, etc., achieving low price, good waterproof performance, and excellent construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

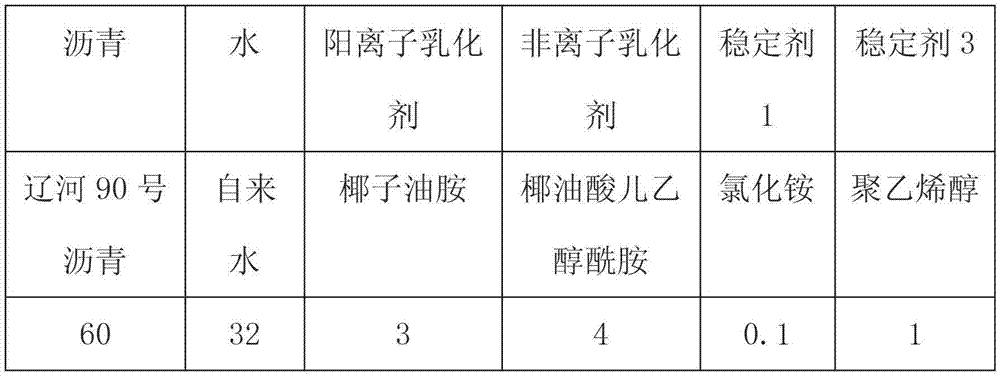

[0040] The emulsified asphalt raw materials in the invented product are proportioned according to the following (Table 1) (weight ratio, the same below):

[0041] Table 1 Formula table of emulsified asphalt (100 parts of emulsified asphalt)

[0042]

[0043] The manufacturing process of emulsified asphalt is as follows:

[0044] (1) Dehydrate the asphalt at 110°C-130°C for 1 hour to 2 hours, then heat it gently to 130°C-160°C, and measure it for later use;

[0045] (2) Heat the tap water to 45°C-65°C and measure it for later use;

[0046] (3) Add the emulsifier and stabilizer to the standby hot water, stir evenly to make an emulsified aqueous solution, control the temperature at 45°C-65°C, and set aside;

[0047] (4) Turn on the emulsifier system, pour the emulsified aqueous solution that meets the temperature requirements into the emulsification, and immediately pour in the hot asphalt that meets the temperature requirements, and the emulsified asphalt that meets the req...

Embodiment 2

[0059] Proportion the emulsified asphalt raw materials according to the following (Table 4) (weight ratio, the same below):

[0060] Table 4 Formula of emulsified asphalt (100 parts of emulsified asphalt)

[0061]

[0062]

[0063] The emulsified asphalt manufacturing process of embodiment 2 is as embodiment 1

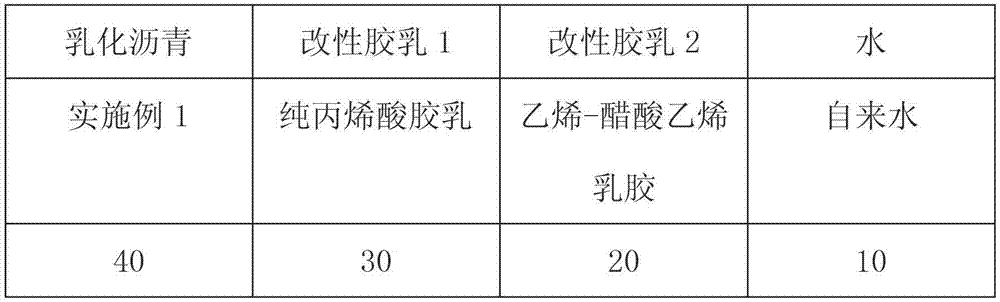

[0064] Then the raw materials in the invention product are proportioned (weight ratio, the same below) as follows (Table 5):

[0065] Table 5 A component of asphalt polymer cement waterproof coating (100 coatings)

[0066] emulsified asphalt Modified Latex 1 Modified latex 2 water Example 1 Pure acrylic latex Styrene Acrylic Latex tap water 40 30 15 15

[0067] Table 6 B component of asphalt polymer cement waterproof coating (100 parts of coating)

[0068] cement filler 1 filler 2 Auxiliary White cement calcium carbonate wollastonite Superplasticizer 50 30 18 2

[0069] The manufacturing...

Embodiment 3

[0071] Proportion the emulsified asphalt raw materials according to the following (Table 7) (weight ratio, the same below):

[0072] Table 7 Emulsified asphalt formula table (100 parts emulsified asphalt)

[0073]

[0074]

[0075] The emulsified asphalt manufacturing process of embodiment 3 is as embodiment 1

[0076] Then the raw materials in the invented product are proportioned according to the following (Table 8) (weight ratio, the same below):

[0077] Table 8 A component of asphalt polymer cement waterproof coating (100 coatings)

[0078]

[0079] Table 9 B component of asphalt polymer cement waterproof coating (100 coatings)

[0080] cement filler 1 filler 2 Auxiliary White cement calcium carbonate talcum powder Superplasticizer 50 33 15 2

[0081] The manufacturing process of the asphalt polymer cement waterproof coating of embodiment 3 is as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com