Construction method of one-time excavation for large-section vertical well

A construction method and large-section technology, which is applied in vertical shaft equipment, earthwork drilling, reverse sinking, etc., can solve the problems of operator injury, increased construction cost, high construction cost, etc., and achieve low construction cost and guaranteed construction safety , the effect of fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

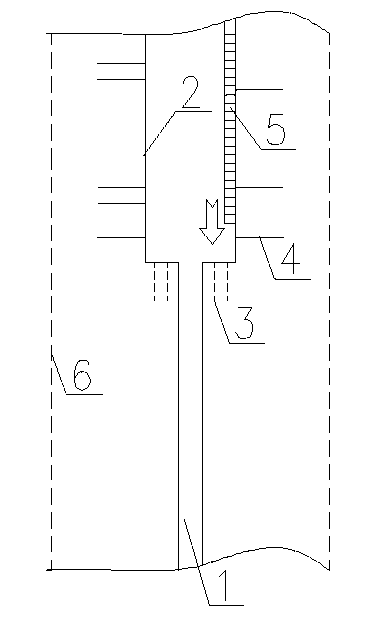

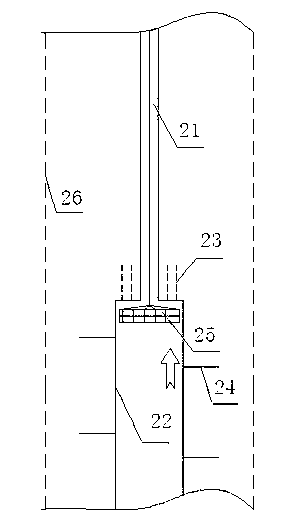

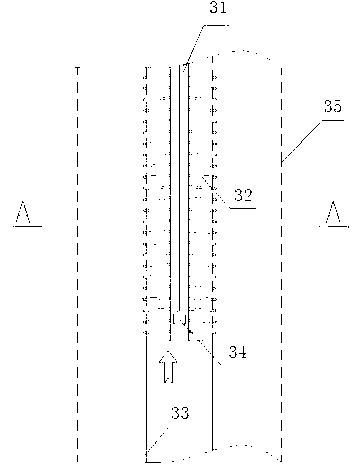

[0014] like image 3 As shown, the present invention uses a raise drilling rig to complete the construction of a 1.4m pilot well, and installs a vertical lifting system at the wellhead, and transports personnel from the wellhead to the pilot well through a hanging cage, and uses the hanging cage as an operating platform, because the working space in the pilot well is small , on the operating platform, a short air-leg hand drill is used to construct approximately horizontal circumferential radiation holes, and the drilling is completed from bottom to top. Finally, a hanging cage is used to cooperate with bottom-up segmental charge and segmental blasting. After blasting The slag material falls to the bottom under the action of gravity, and then the slag is discharged, and the excavation of the guide shaft is completed in sections from bottom to top. Using this method, the 1.4m guide shaft is enlarged into a 3.5m slag well, which can be used in a relatively small area. In a short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com