A method to balance mass moments of a drive unit and drive unit for performance of such a method

A transmission unit and moment of inertia technology, which is applied in the direction of inertial force compensation, machine/engine, crankshaft, etc., can solve the problem that the balance counterweight cannot be set on the same carrier, and achieve weight reduction, fuel consumption reduction, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

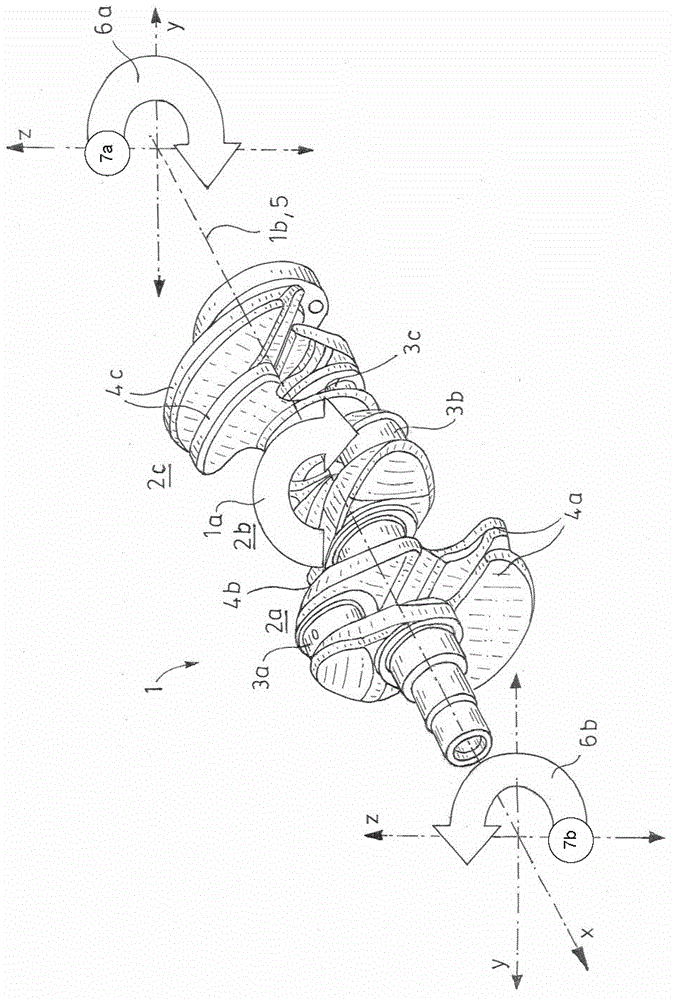

[0045] In the prior art, the sum of force pairs comprising the inertial forces of two balance weights rotating in the same direction is added, and the resultant moment is the so-called free moment, which is and remains equally large with respect to any reference point , compared with the prior art, the method according to the invention is characterized in that, due to the counterweight rotation in the opposite direction, the free resultant force is maintained, and the magnitude of the combined moment is such that the first-order velocity caused by the rotation of the rigid body around the transmission unit The rotational motion caused by the first-order resultant moment of inertia of the polar center is balanced.

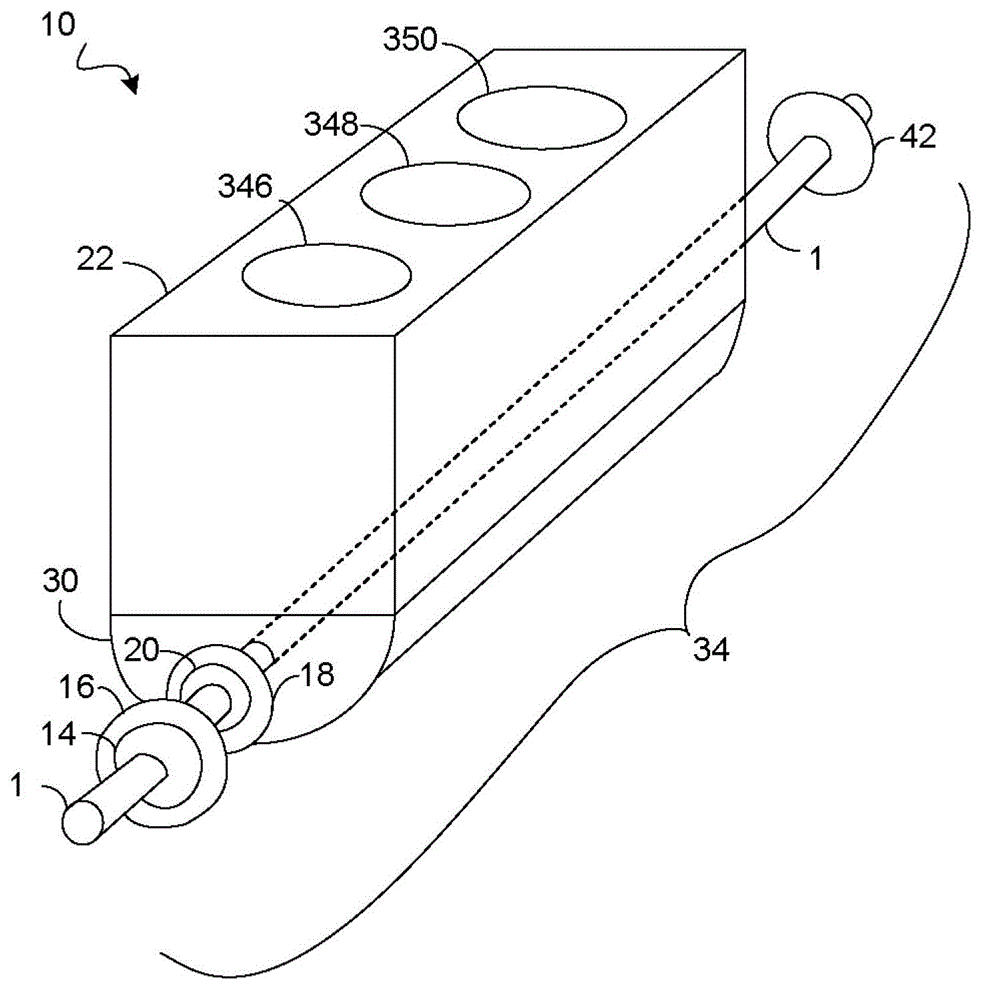

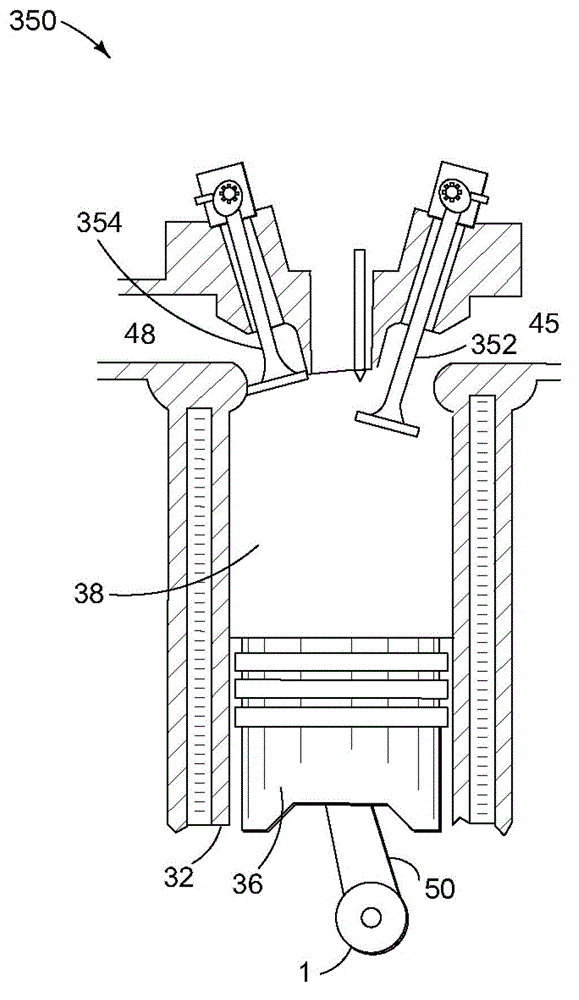

[0046] The present invention provides a system and method of at least partially balancing a crank drive that requires less space and is lighter than prior systems. This method utilizes two balance weights that may be placed on the crank drive member. The two balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com