An Electrowetting Piston Optical Switch

A technology of electrowetting piston and optical switch, which is applied in the field of optical communication to achieve the effects of rich control means, improved yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

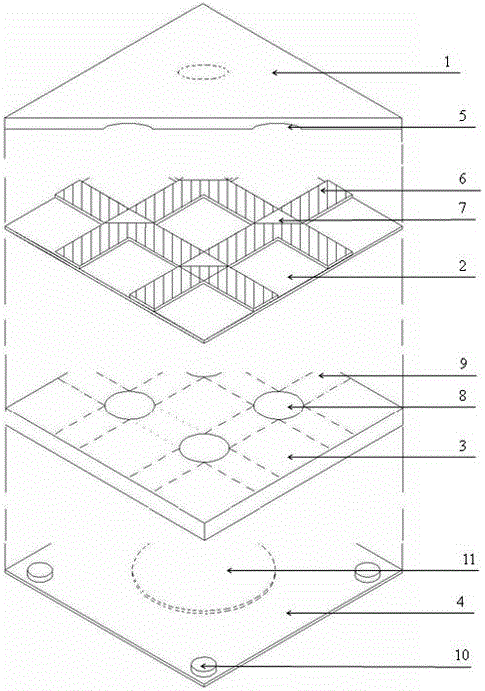

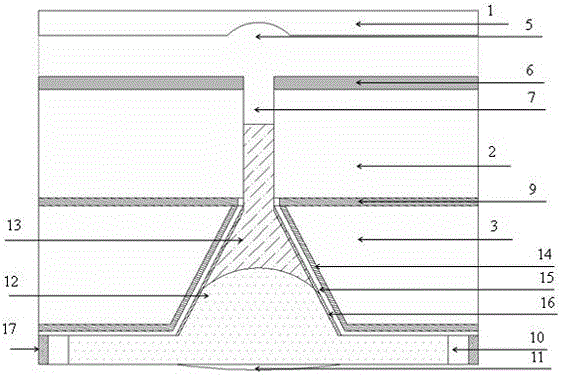

Embodiment 1

[0028] The upper cover plate is made of materials that are easy to make holes, have a small coefficient of thermal expansion, and can be mass-produced, and are preferably heat-insulating hard plastics, which can be formed by injection molding. The waveguide plate is made of a material that is easy to make smooth triangular through holes, preferably the same material as the upper cover plate and is formed by injection molding. The mesh waveguide structure is made of ultraviolet photoresist. The main body of the inner core of the electro-wetting piston can be molded with ABS plastic, and the surface is completely formed by electroplating a metal conductive layer inside the electro-wetting drive through hole, and then the control electrode and circuit are prepared on the upper surface by corrosion method; all the conductive layers are wrapped with a layer of insulation The layer is preferably parylene with a thickness of 3 microns produced by a vacuum coating method; the hydrophob...

Embodiment 2

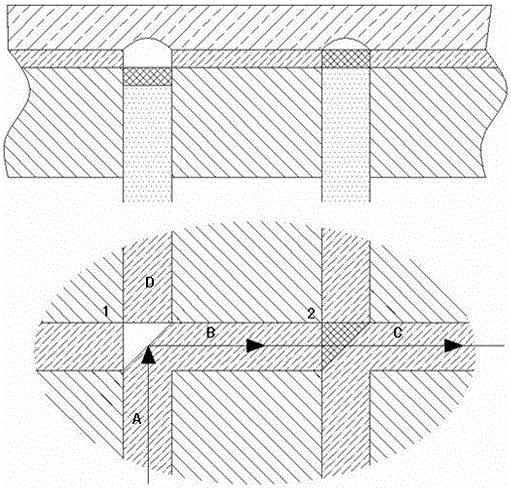

[0032] Since the micro-fluid cavity of the waveguide node is very small, it is difficult for the injected liquid to reach the designated position. The air cavity of the upper cover plate can be made into a small hole with an elastic film, and a pressure adjustment device is added outside the elastic film of the upper and lower cover plates. Pressurization makes the liquid column in the micropore stop at the designated position, and it can also be used as an auxiliary device for zero adjustment when the temperature changes too much. In special cases, the waveguide substrate and the mesh waveguide array on it can be integrally produced by injection molding, and the matching liquid can be omitted at the same time.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap