Air filtering material with sterilization and disinfection functions

An air filter material, sterilization and disinfection technology, applied in the direction of disinfection, disinfectant, biocide, etc., can solve the problems of human injury, large investment and high use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: A closed laboratory (similar to an ordinary room)

[0013] Select a certain air purifier as the test prototype. The original air filter of the air purifier has an overall size of 135×115×15 (mm). Based on this, the frame of the air filter and the non-woven material for the air filter are made first. Then put about 130 grams of the prepared air filter material into a non-woven bag and sew it up, and finally put the bag containing the air filter material into the frame of the air filter. So far, the air filter with sterilization function Finished. .

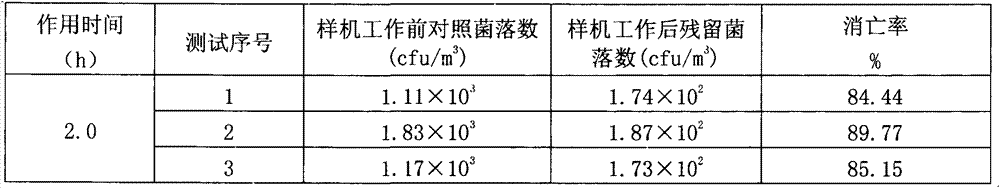

[0014] The actual sterilizing and disinfecting effect test data of the air purifier equipped with a sterilizing and disinfecting filter is as follows:

[0015] 1. Testing equipment and place

[0016] 1. Prototype: an air purifier equipped with a sterilizing filter, the production date is 2010.10.15

[0017] 2. Microbial sampler: FA-1 six-stage sieve air impact sampler.

[0018] 3. Medium: nutrient agar.

...

Embodiment 2

[0034] Embodiment 2: A closed laboratory (simulated elevator car)

[0035] A certain type of elevator fan was selected as the test prototype. The elevator fan was originally an ordinary fan that only ventilated the elevator car. Now, an air filter with sterilization and disinfection functions is installed in the middle of the air inlet. The specific specification of the air filter is 150 × 100 × 15 (mm), about 120 grams of sterilizing and disinfecting functional materials are housed in the filter, and the preparation method of the air filter is the same as above. In this way, the elevator fan becomes an elevator fan with sterilization and disinfection functions, and it can not only make the elevator car ventilate , It can also sterilize and disinfect the air in the elevator car, which is very suitable for elevators used in some public places (such as elevators in hospitals).

[0036] The actual sterilizing and disinfecting effect test data of the elevator fan equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com