Novel capsicum fermentation technology

A pepper and process technology, applied in the field of new pepper fermentation technology, can solve the problems of food quality, color degradation, uncontrollable food safety problems, etc., and achieve the effects of reducing foreign matter and pesticide residues and solving single flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

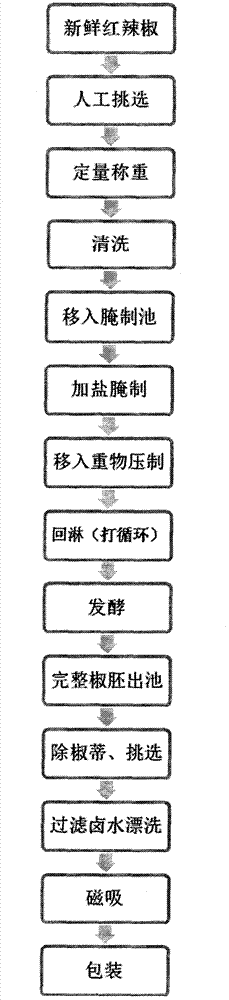

Image

Examples

Embodiment Construction

[0007] 1. Selection: Remove foreign objects such as pepper leaves, pepper stems, rubber ropes, and hair, and pick out worm peppers, rotten peppers, green peppers, diseased peppers, and exotic peppers.

[0008] 2. Cleaning: Use pepper cleaning equipment to clean sand, sand, foreign matter and other debris, and drain.

[0009] 3. Marinated:

[0010] (1) add salt by 19-20% of capsicum weight, adopt the table salt of food grade.

[0011] (2) Salt addition method: put a layer of pepper and sprinkle a thin layer of salt, pay attention to uniformity.

[0012] (3) After the pool is full, a layer of food-grade fine plastic mesh (40 mesh) is laid on the surface of the pepper, and then pressed with a weight.

[0013] (4) The standard range of pressure for pressing peppers with heavy objects: 3500-4500Pa.

[0014] 4. Back showering (circulation) fermentation:

[0015] (1) During the first week, peppers need to be drenched once a day.

[0016] (2) One week later, the frequency of rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com