Internal mold and manufacturing method thereof, and precast box girder and manufacturing method thereof

A production method and internal mold technology, applied in bridges, molds, manufacturing tools, etc., can solve the problems of corner deformation, structural size excess, inelastic deformation, etc., to achieve strong deformation resistance, simplified installation difficulty, and low self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

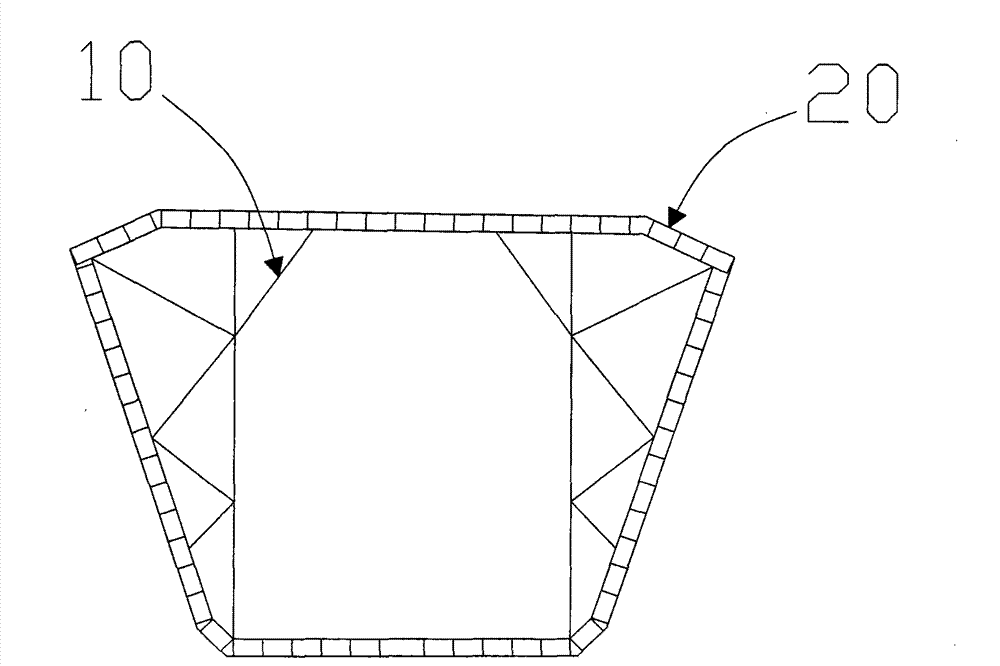

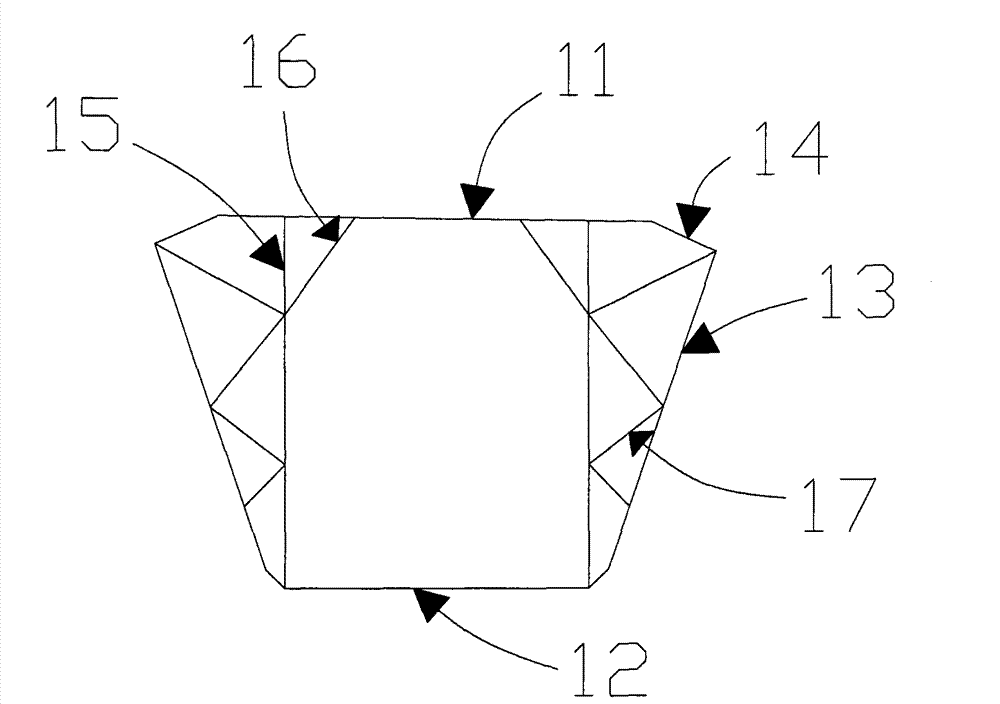

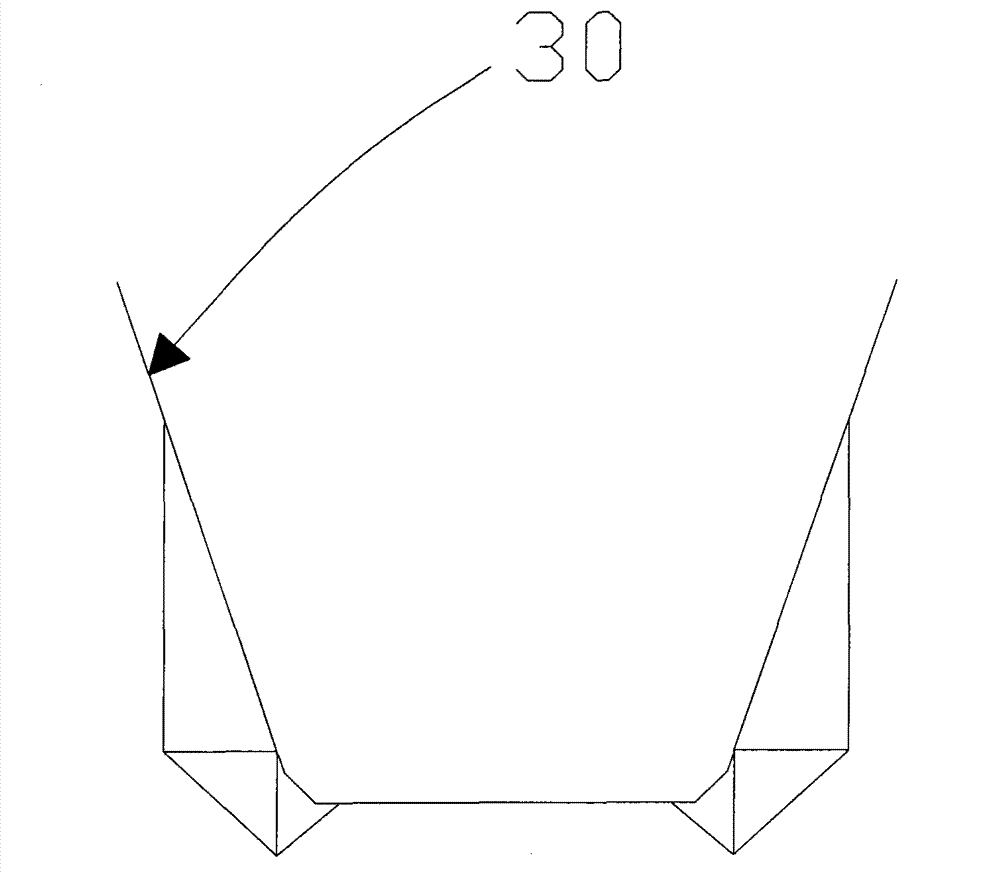

[0043] The invention discloses an inner mold of a prefabricated box girder. The inner mold includes a skeleton piece and an inner mold panel formed by splicing a plurality of long strip steel materials. The inner mold panel is fixed around the outer side of the skeleton piece.

[0044] The present invention uses skeleton sheets to build the entire internal skeleton, and the inner mold panel is formed by splicing long strips of steel, and the long strips of steel are fixed on the outside of the skeleton sheet. The steel can be fixed on the outside of the skeleton one by one. The whole process can be completed manually or with the help of small auxiliary tools. There is no need to use heavy machinery such as small gantry cranes, which simplifies the difficulty of installation; when disassembling, just remove the long strips of steel. The inner mold can be naturally disintegrated when connected with the skeleton piece, and the disassembly is convenient and time-consuming. In addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com