Yacht made of bamboo composite material and its manufacturing process

A technology of composite materials and yachts, which is applied in shipbuilding, shipbuilding, non-magnetic metal hulls, etc., can solve the problems of high manufacturing cost, insufficient rigidity, and non-environmental protection, and achieve less production personnel, high production efficiency, and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

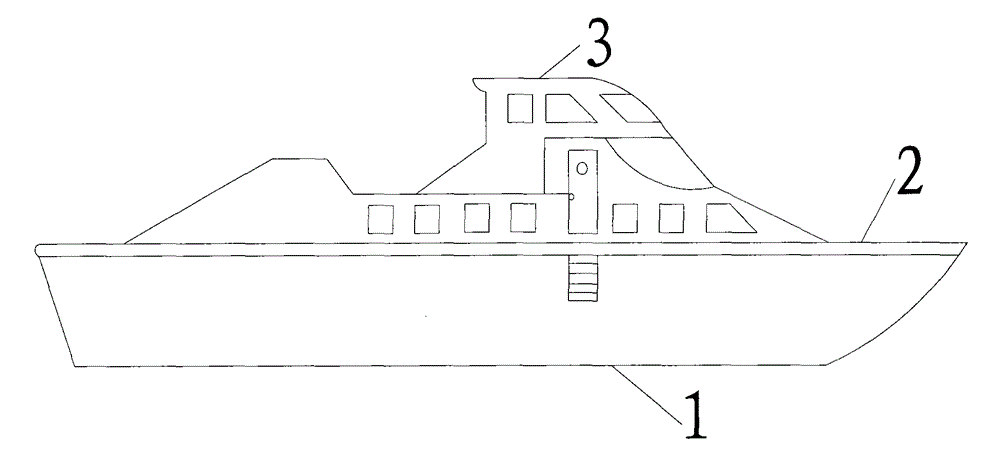

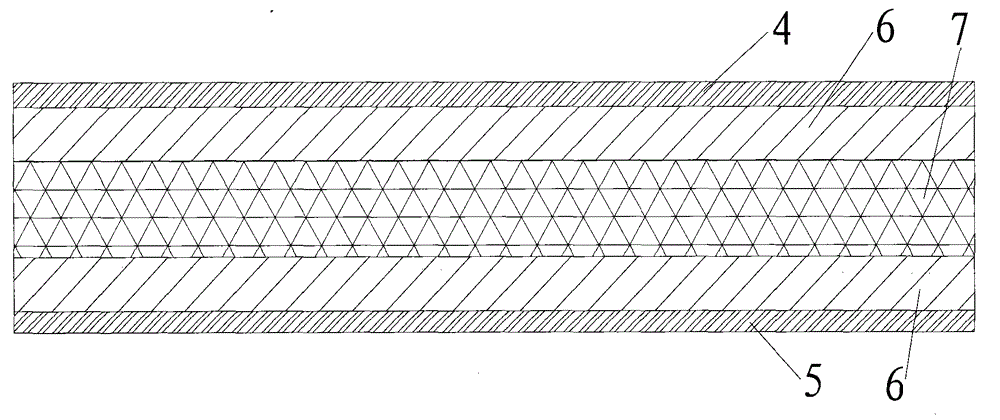

[0026] A yacht made of bamboo composite material is mainly composed of a hull. The hull includes a hull bottom plate 1, a hull deck 2 and a roof deck 3. The hull bottom plate 1, hull deck 2 and roof deck 3 are connected together by connecting pieces. The hull bottom plate, Both the hull deck and the roof deck are formed by vacuum infusion of the outer glass fiber or carbon fiber fabric layer 4, the base material layer 6, the bamboo fiber lath layer 7, the base material layer 6 and the inner glass fiber or carbon fiber fabric layer 5, and the base material layer 6 The matrix material is the mixture of epoxy resin / polyester resin and solidifying agent, is filled with matrix material in the bamboo fiber lath layer 7, and the bamboo fiber plate of bamboo fiber plate layer 7 is that bamboo is processed and disentangled into bamboo fiber bundles, and then through processing, making Become a bamboo fiber laminated board, after compaction, the strip-shaped object formed by cutting or b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com