Blended yarns of seaweed fibers, wools and polysulfonamide fibers, shell fabric and production process

A technology of seaweed fiber and production process, which is applied in the field of multi-fiber blended yarn, production technology and its fabric, blended yarn of wool and aramid fiber, and seaweed fiber, and achieves comfortable wearing, good dyeability, and excellent flame retardancy. functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Spinning

[0024] (1) Spinning specifications

[0025] Seaweed fiber / wool / aramid fiber: 30% / 0% / 70%

[0026] Yarn density ①Weaving yarn 14.8tex; ②Knitting yarn 18.5tex

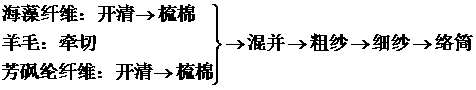

[0027] (2) Process flow

[0028] 30% of seaweed fiber + 70% of aramid fiber (first mixing fully and evenly manually) → opening and cleaning (including multi-bin blender) → carding → drawing (head, double) → roving → spinning → winding

[0029] a. Open the cotton

[0030] The fiber used in the present invention has good uniformity, only needs to remove the hard and silky fibers in the fiber, and after the seaweed fiber and the aramid fiber are fully mixed and uniformly artificially, the cotton blower adopts a lower speed and gentle opening process. The speed is controlled within 400~750r / min to reduce fiber damage.

[0031] b. Carding process

[0032] The FA231A carding machine is selected, the cylinder speed is 320r / min, the licker roller speed is 650r / min, the 5-point pitch of the cylinder cover is 0.30, 0.28, 0...

Embodiment 2

[0054] (1) Spinning

[0055] (1) Spinning specifications

[0056] Seaweed fiber / wool / aramid fiber: 25% / 15% / 60%

[0057] Yarn density 58.5tex

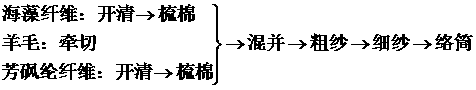

[0058] (2) Process flow

[0059]

[0060] a. Open the cotton

[0061] The seaweed fiber and aramid fiber are separately opened and cleaned into rolls, and the uniformity of the rolls is less than 0.8%. The fiber used in the present invention has good uniformity, and only needs to remove the hard yarns in the fiber. The beaters of the opener and cleaner adopt a lower speed and gentle opening process, and the speed of each beater is controlled within 400-750r / min to reduce fiber damage.

[0062] b. Carding process

[0063] The FA231A carding machine is selected, the cylinder speed is 320r / min, the licker roller speed is 650r / min, the 5-point pitch of the cylinder cover is 0.30, 0.28, 0.28, 0.28, 0.30 (mm), and the total draft ratio is 112 , Sliver quantitative 18.5g / 5m.

[0064] c. Wool draft-cutting: worsted wool tops are draft-cut, the fiber lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com