Single-sided velvet and preparation method thereof

A single-face and single-face technology, which is applied in the direction of cutting pile loops, vibration processing, and textile material processing, can solve functional limitations and other problems, and achieve excellent antibacterial and meet-demand effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

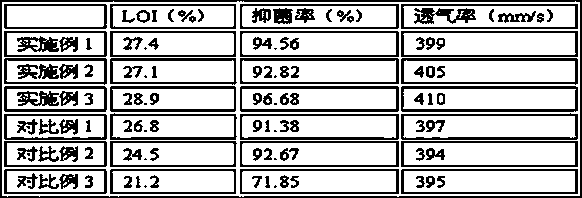

Examples

Embodiment 1

[0024] A kind of single face cashmere and preparation method thereof, concrete steps are as follows:

[0025] (1) In the weaving step, 100D48F low-elasticity polyester yarn and 150D72F low-elasticity polyester yarn are woven into loop gray fabric through single-sided weft-knitted terry weave through large circular knitting machine;

[0026] (2) Napping and raising step, using a napping machine to process 150D72F low-elastic polyester yarn through napping processing to obtain a loop structure, and then use dense steel needles to break the loops to form fluff with a certain velvet feel, and prepare single-faced velvet;

[0027] (3) Soaking step, immerse the single-face cashmere to be treated in the thinner (deionized water) diluted

[0028] In ultraviolet (UV) light-curing coatings, the ratio of coatings to deionized water is calculated as 3~5:1 by weight, and the immersion time is 3~5h. The air permeability of the functional coating formed after coating, the bubbles are genera...

Embodiment 2

[0040] Example 2: The difference from Example 1 is that the composition content of ultraviolet (UV) photocurable coatings is different, and the coatings are calculated in parts by weight, including: 35 parts of epoxy acrylate resin, 10 parts of epoxy resin, and 5 parts of acrylic emulsion , 7 parts of glycerol, 20 parts of K550 silane coupling agent, 1 part of organic phosphorus flame retardant, 1 part of nano magnesium hydroxide, nano SiO 2 1 part, 5 parts of irgacure 2959 photoinitiator, 1 part of defoamer, 1 part of terpene rosin resin and 5 parts of reactive diluent.

Embodiment 3

[0041] Example 3: The difference from Example 1 and Example 2 is that the composition content of ultraviolet (UV) photocurable coatings is different, and the coatings are calculated in parts by weight, including: 40 parts of epoxy acrylate resin, 15 parts of epoxy resin, 7 parts of acrylic emulsion, 8 parts of glycerin, 25 parts of K550 silane coupling agent, 5 parts of organic phosphorus flame retardant, 3 parts of nano magnesium hydroxide, nano SiO 2 5 parts, 7 parts of irgacure 2959 photoinitiator, 3 parts of defoamer, 3 parts of terpene rosin resin and 7 parts of reactive diluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com