Waterproof flame-retardant coating for wood lampshade and preparation method thereof

A technology for flame-retardant coatings and lampshades, applied in the field of coatings, can solve the problems of poor waterproof, flame-retardant and wear-resistant effects, and achieve the effects of remarkable friction resistance, excellent waterproof and flame-retardant functions, and good protection and decoration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

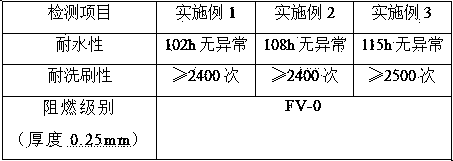

Embodiment 1

[0009] This embodiment provides a waterproof and flame-retardant coating for wooden lampshades, which contains the following components in parts by mass: 10 parts of pentaerythritol, 8 parts of melamine, 15 parts of talcum powder, and 6 parts of tris(2,3-dichloropropyl) phosphate , 1 part of borate, 5.8 parts of dioctyl phthalate, 15 parts of water, 12 parts of urea, 0.06 part of simethicone, 0.2 part of dichromium trioxide, 0.05 part of alkylphenol polyoxyethylene ether, poly Acrylamide emulsion 90 parts, pigment 0.5 part.

[0010] The preparation steps of a kind of waterproof flame-retardant coating for wooden lampshade are as follows: add pentaerythritol, melamine, talcum powder, tris (2,3-dichloropropyl) phosphate, borate, dioctyl phthalate and water In the mixer, stir and mix for 0.5h, then add the pigment and mix evenly, then carry out ball milling, discharge the material after ball milling for 12h, then mix evenly with urea, dimethyl silicone oil, alkylphenol polyoxyeth...

Embodiment 2

[0012] This embodiment provides a waterproof and flame-retardant coating for wooden lampshades, which contains the following components in parts by mass: 22 parts of pentaerythritol, 20 parts of melamine, 25 parts of talcum powder, and 14 parts of tris(2,3-dichloropropyl) phosphate , 2.2 parts of borate ester, 13.2 parts of dioctyl phthalate, 25 parts of water, 20 parts of urea, 0.14 part of simethicone, 0.5 part of dichromium trioxide, 0.15 part of alkylphenol polyoxyethylene ether, poly Acrylamide emulsion 105 parts, pigment 1.3 parts.

[0013] The preparation steps of a kind of waterproof flame-retardant coating for wooden lampshade are as follows: add pentaerythritol, melamine, talcum powder, tris (2,3-dichloropropyl) phosphate, borate, dioctyl phthalate and water In the mixer, stir and mix for 0.5h, then add the pigment and mix evenly, then carry out ball milling, discharge the material after ball milling for 12h, then mix evenly with urea, dimethyl silicone oil, alkylphe...

Embodiment 3

[0015] This embodiment provides a waterproof and flame-retardant coating for wooden lampshades, which contains the following components in parts by mass: 16 parts of pentaerythritol, 14 parts of melamine, 20 parts of talcum powder, and 10 parts of tris(2,3-dichloropropyl) phosphate , 1.6 parts of borate ester, 9.5 parts of dioctyl phthalate, 20 parts of water, 16 parts of urea, 0.1 part of dimethyl silicone oil, 0.35 parts of dichromium trioxide, 0.1 part of alkylphenol polyoxyethylene ether, polyoxyethylene ether Acrylamide emulsion 98 parts, pigment 0.9 part.

[0016] The preparation steps of a kind of waterproof flame-retardant coating for wooden lampshade are as follows: add pentaerythritol, melamine, talcum powder, tris (2,3-dichloropropyl) phosphate, borate, dioctyl phthalate and water In the mixer, stir and mix for 0.5h, then add the pigment and mix evenly, then carry out ball milling, discharge the material after ball milling for 12h, then mix evenly with urea, dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com