Debris flow diversion dam capable of automatically distributing drainage quantity and silt stopping quantity and design method of debris flow diversion dam

An automatic distribution and diversion dam technology, which is applied in the direction of dams, river improvement, sea area engineering, etc., to achieve the effects of saving investment, preventing secondary disasters, and reducing the height of the dam body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

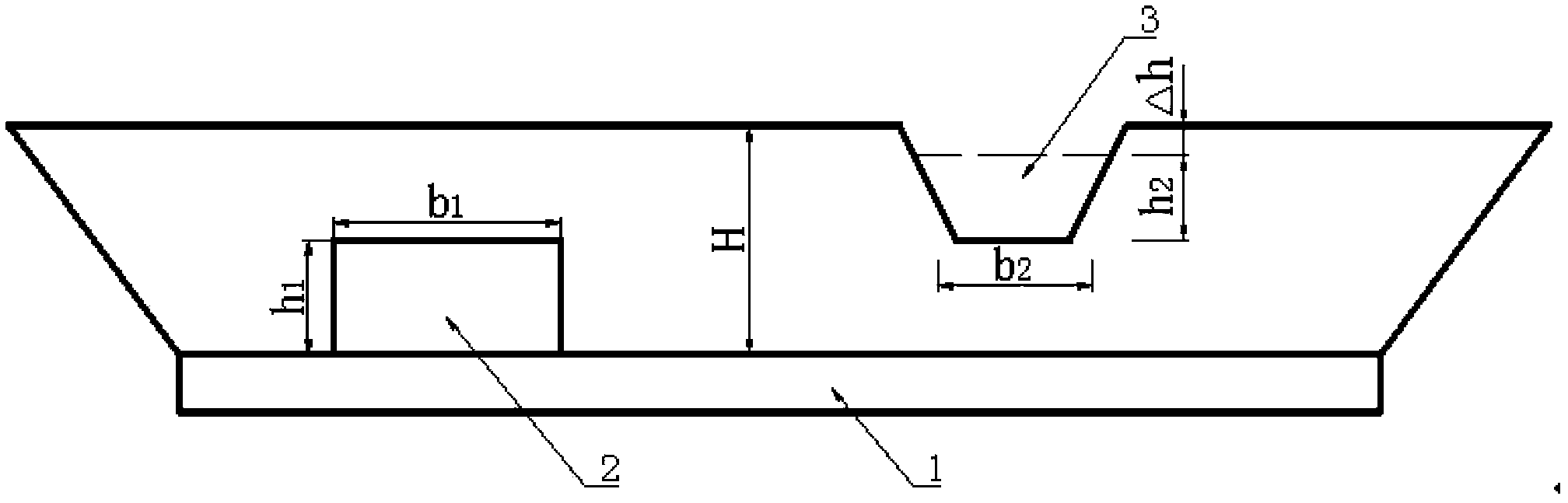

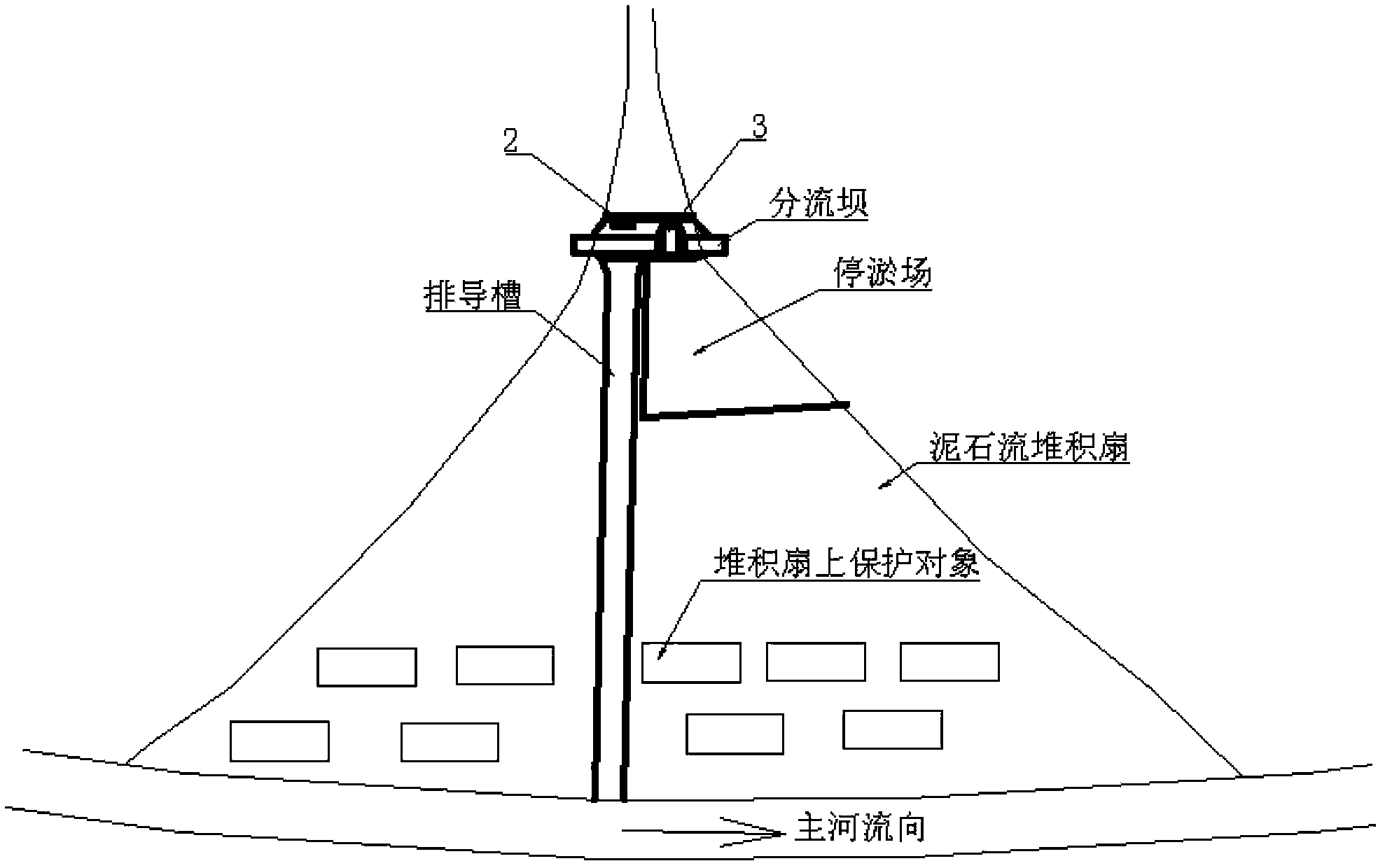

[0027] Such as figure 1 , figure 2 shown. The drainage area of a debris flow ditch is 5.6km 2 , in order to control debris flow disasters, the prevention and control plan of building sand-blocking dams in the ditch, building a silt stop with accumulation fans, and a 4.0m bottom width row channel is adopted. For the 40m wide channel at the top of the accumulation fan, it is proposed to plan a diversion dam to distribute The amount of drainage and silting, the layout of the plane position is as follows: figure 2shown. The debris flow diversion dam that automatically distributes the amount of drainage and silting includes a dam body foundation 1 and a dam body body located on the dam body foundation 1; the bottom of the dam body body is provided with a diversion hole 2 connecting the row guide groove, The top of the main body of the dam body is provided with a diversion weir 3 connected to the silt stop; The cross-sectional size is determined according to the design flow...

Embodiment 2

[0033] Such as figure 1 , figure 2 shown. The same places as in Embodiment 1 will not be repeated, the difference is that the drainage area of a certain debris flow ditch is 16.8km 2 , using the prevention and control plan of building a sand trap group in the ditch, building a silt stop with accumulation fans, and a 6.0m-bottom width row channel. The design flow rate Q of the guide groove drainage 84.0m 3 / s, the design flow Q of the parking lot deposit 62.0m 3 / s. The main body of the dam body is made of masonry material.

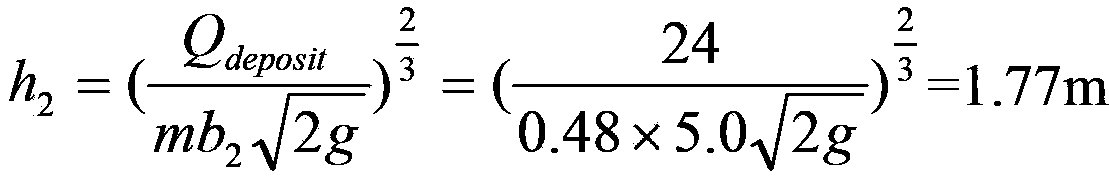

[0034] In the first step, the average width of the diversion weir 3 is preliminarily set b 2 is 5.0m, and the discharge coefficient m is taken as 0.46 according to the main material of the dam body, according to the formula h 2 = ( Q deposit m b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com