Dam foundation reinforcement frame structure and dam foundation reinforcement method

A frame structure and dam foundation technology, which is applied in basic structure engineering, construction, etc., can solve the problems of low strength, dam foundation settlement control, insufficient anti-slip stability of dam slope, small pile diameter, etc., so as to improve stability and improve dam foundation settlement control. and dam slope anti-sliding stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

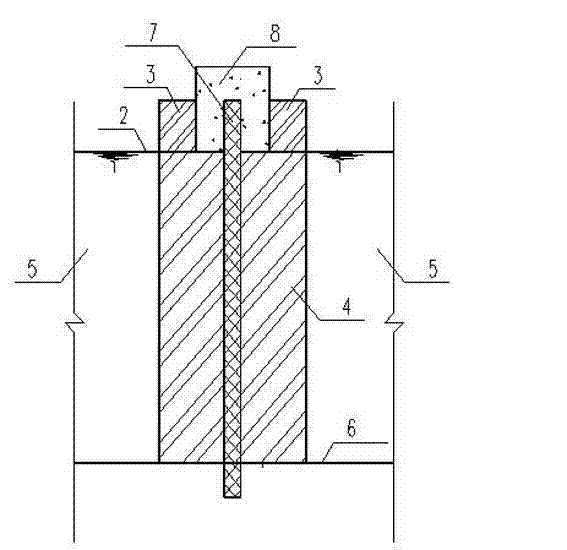

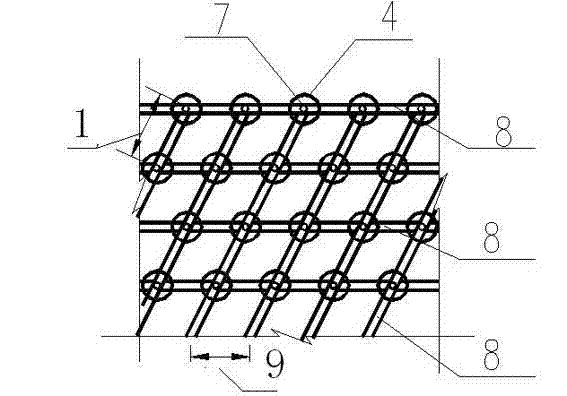

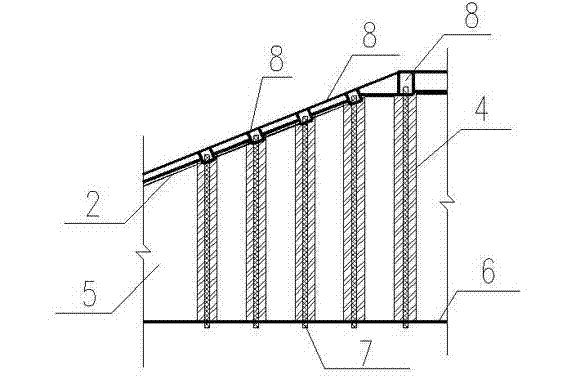

[0029] A dam foundation reinforcement frame structure, comprising a plurality of pile bodies 4 whose main body is arranged in the soft foundation 5 of the dam foundation, the bottom ends of the pile bodies 4 reach the boundary line 6 of the rock foundation, and the top ends exceed the ground line 2, and the pile bodies exceed the ground The part outside the line is the laitance section 3 that can be chiseled out; at least one reinforcement 7 is provided in the pile body, and the bottom section of the reinforcement exceeds the rock foundation boundary line 6, and the top exceeds the ground line 2; the laitance section can be chiseled through 3 and the reinforcing piece 7 fixedly connect the concrete grid beam 8 .

[0030] Both the tops of the pile body 4 and the reinforcement 7 exceed the ground line by more than 0.3m; the bottom of the reinforcement 7 exceeds the boundary line of the rock foundation by more than 0.2m. The pile body 4 is a high-pressure rotary spraying pile bod...

Embodiment 2

[0032] A dam foundation reinforcement method, the specific construction method is as follows:

[0033] (1) Use a high-jet grouting machine to spray cement slurry into piles. The top elevation of the high-pressure rotary jet grouting should be 0.3m higher than the ground, so that the laitance of the pile head can be cut off later, and the weak parts of the pile body can be removed. The bottom elevation of high-pressure jet grouting to the bedrock boundary.

[0034] (2) Before the initial setting of the cement slurry, start the vibration mode of the high-jet grouting machine, and quickly lower the steel pipe into the high-pressure jet grouting pile.

[0035] (3) When reaching the bedrock boundary, due to the high resistance of the bedrock, the vibrating frequency can be increased according to the actual situation. Generally, the vibrating frequency is controlled at 20HZ~40HZ.

[0036] (4) Drive the steel pipe into the bedrock 0.2m, so as to improve the stability of the pile by...

Embodiment 3

[0039] Example 3: Application

[0040] The dam foundation reinforcement frame structure of the present invention has been used in a pumped storage power station. The homogeneous earth dam crest elevation of the reservoir under the power station is 24.4m, the reservoir bottom elevation is -2.0m, the normal storage level elevation is 19.0m, and the stagnant water level elevation is 0m.

[0041] The geological conditions of the lower reservoir are extremely complex, the upper silty clay is 2.0-5.0m thick, the silty clay is 0-8.0m thick, and the sandy gravel layer is 2.20-5.50m thick. The silty soil is distributed at an elevation of 7.0-15.0m, located below the water level of the reservoir, and the silty clay is thicker in the area around 350m long on the north side of the homogeneous earth dam, which is 3-8m. The silty clay is soft and plastic, a small amount is even liquid plastic, contains a small amount of crushed stone or gravel, and has extremely poor stability.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com