Multifunctional plug valve

A plug valve, multi-functional technology, applied in the field of plug valves, can solve the problems of single function, reduced valve life, large medium overflow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

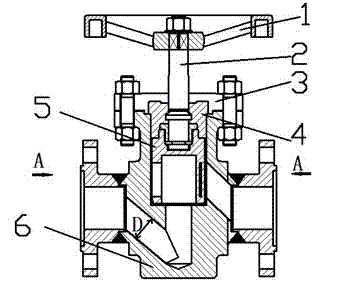

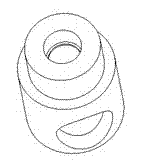

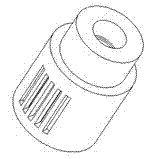

[0017] like figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a driving mechanism 1, a valve stem 2, a valve cover 3, a pressure plate 4, a valve core, and a valve body 6; the rotating shaft of the driving mechanism 1 drives the valve core to rotate through the valve stem 2. The valve core 5 is evenly distributed in the circumferential direction with two cross-distributed working surfaces and two sealing surfaces, and the valve core and the hard sealing ring surface welded on the inner outlet edge of the plug valve form a rotary sealing pair; one working surface of the valve core is There are through holes; the inner and outer circles of the other working surface of the spool are respectively provided with a group of interlaced straight grooves of the same size, and the inner straight grooves and outer straight grooves are connected through the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com