Modularization vibration resisting method of gas turbine waste heat boiler

A waste heat boiler, modular technology, applied in the direction of boiler support/positioning device, etc., can solve the problems of tube bundle fin damage, looseness, violent swing, etc., to reduce tube shaking and wear, to ensure normal production order, and to be reliable operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

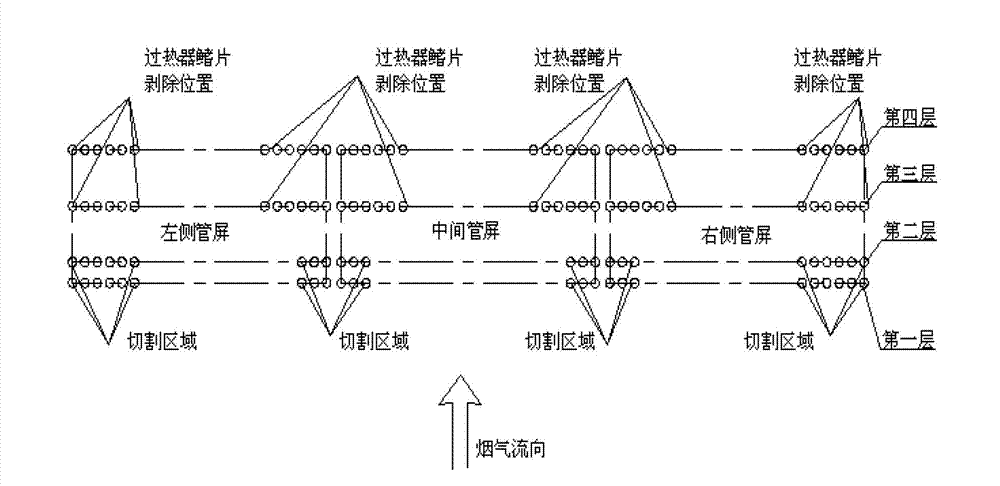

[0026] The present invention will be described in detail below by taking the 90MW gas-steam combined cycle generator set used by the applicant as an example. The model of the 90MW gas-steam combined cycle generator set used by the applicant is M701F gas turbine, and the model of waste heat boiler matched with this gas turbine is NG-M701F-R. The large area of the vibration support is loose, and the fin tube shakes irregularly and violently, rubbing against the falling support and the anti-vibration beam, the fin is worn off, and the tube is worn through. Using the modular structure of the waste heat boiler, the flue gas of the waste heat boiler is direction, the reheated surface tube panel and the superheated surface tube panel are reinforced in turn;

[0027] 1) The reinforcement treatment of the reheated surface tube screen includes the following steps:

[0028] ①Remove the 2nd to 4th anti-vibration brackets, remove the detached part of the original anti-vibration bracket ...

specific Embodiment

[0049] Further, when removing the second to fourth anti-vibration brackets in step 1), the large area of the original anti-vibration brackets of the reheated surface tube screen is loosened, the fin tubes are irregularly shaken violently, and the falling brackets and anti-vibration brackets are dislodged. The vibrating beam is rubbed, the fins are worn off, and the tube is worn through. Remove the anti-vibration brackets remaining on the reheating surface in the second to fourth anti-vibration brackets, and keep the horizontal bars and support brackets behind the reheating surface. Take off, re-weld and fix the horizontal bar and support frame; peel off the fins of about 100mm above and below the 3 standard tube bundles of the 2nd to 4th anti-vibration brackets to make them into light pipes.

[0050] Further, when the finned tubes of the reheating surface are cut off in step 1), the 6 finned tubes on both sides of each tube panel on the reheating surface and the finned tubes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com