Full-automatic filtering device of water sample of in-situ environment water body monitor

A filter device and monitor technology, applied in the direction of filtration separation, fixed filter element filter, preparation of test samples, etc., can solve the problems of sample contamination and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

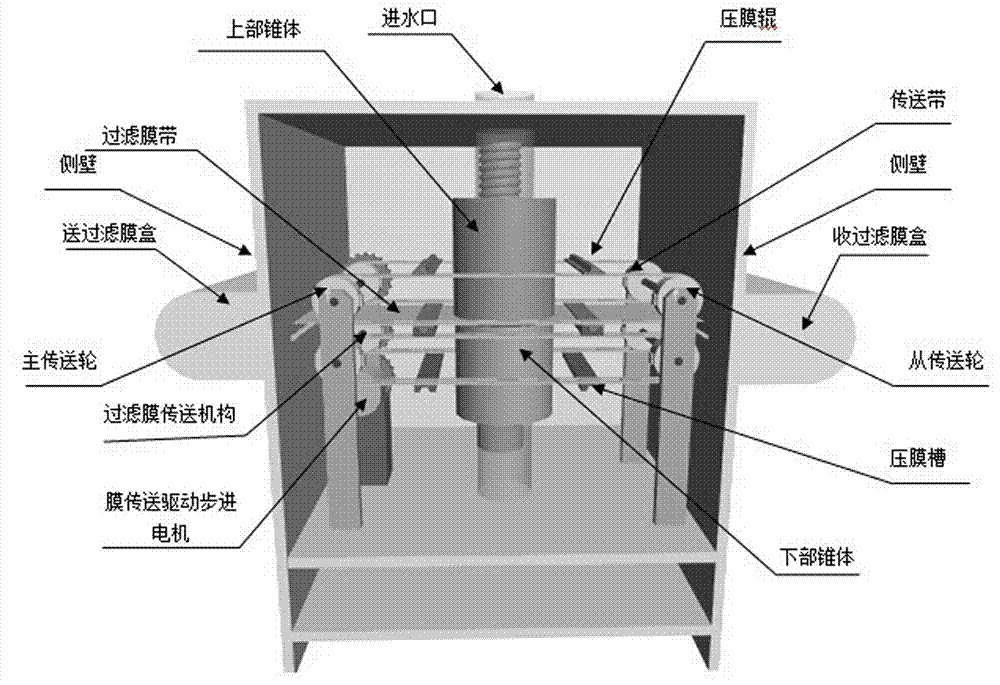

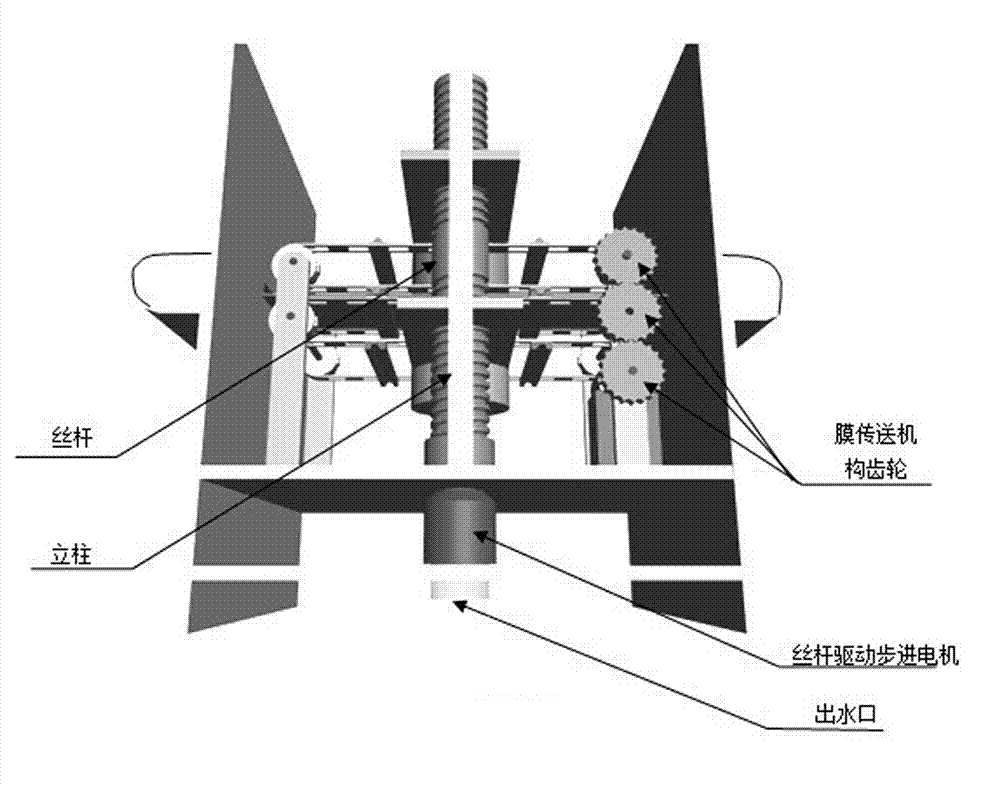

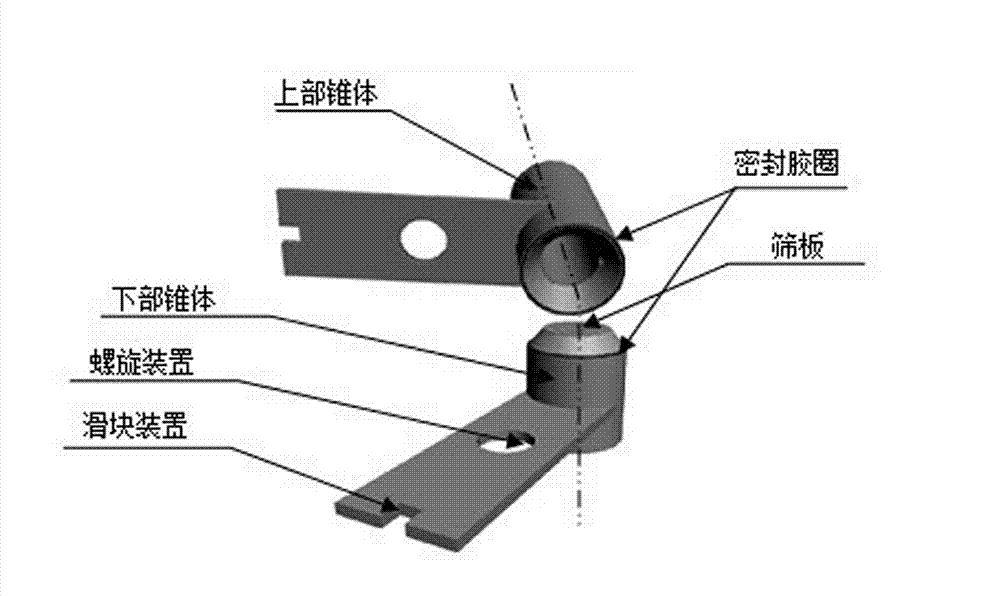

[0028] See figure 1. The automatic filtration device for water samples of the in-situ monitoring instrument for environmental water bodies of the present invention is to arrange the reel-shaped filter membrane belt in the filter membrane box outside the device shell, and the lead of the filter membrane band passes through the device and is fixed on the device shell. On the reel (not shown in the figure) connected to the film collection stepper motor (not shown in the figure) in the other outer filter film box, a filter film transmission mechanism is set in the device, and a part of the filter film belt in the device It is located between the corresponding vertebral bodies (upper vertebral body and lower vertebral body) of a pair of central holes that can be tightly joined or completely separated. figure 2 ) are connected to the central hole of the vertebral body, respectively.

[0029] Here, the filter membrane strip is passed through the device in a horizontal strip. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com