Vertical coupling grating coupler bonded by metal and manufacturing method thereof

A grating coupler and vertical coupling technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of increasing the difficulty of device packaging and reducing the coupling efficiency in the vertical direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

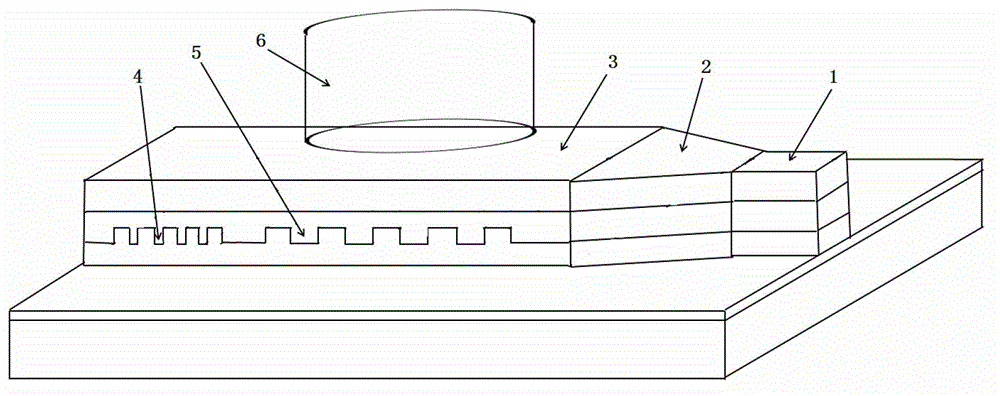

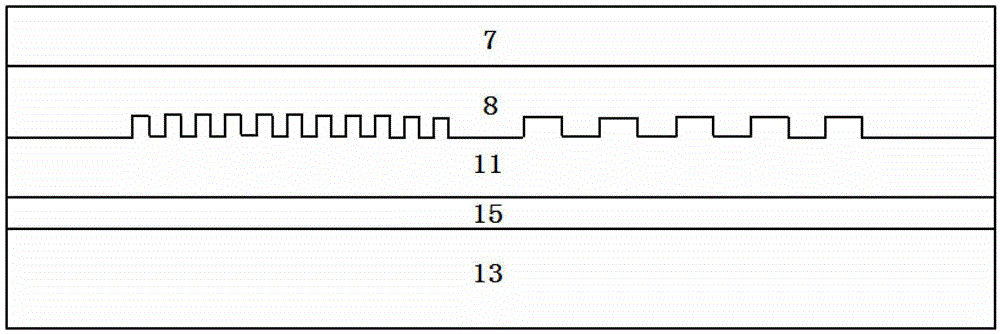

[0054] The structure and features of the present invention will be further described in detail below in conjunction with the drawings and embodiments. Such as figure 1 , figure 2 As shown, a metal-bonded vertical coupling grating coupler, including:

[0055] A carrier sheet 13, which is a silicon sheet or a glass sheet;

[0056] A reflective mirror layer 15 doubles as a bonding layer, and the reflective mirror layer is made of gold material; the thickness of the reflector is not less than 50nm; it can highly reflect the vertically downward diffracted light of the coupling grating, so as to improve the distance between the silicon waveguide core layer 8 and the optical fiber 6. Coupling efficiency between;

[0057] A lower confinement layer 11, the lower confinement layer 11 is a DVS-BCB material;

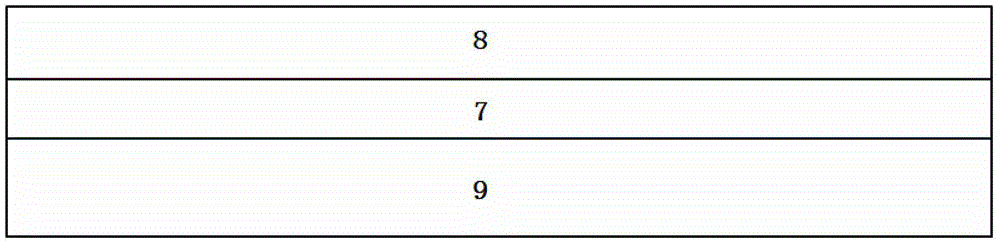

[0058] A silicon waveguide core layer 8, the waveguide core layer 8 is fabricated under the upper confinement layer 7; the thickness of the waveguide core layer 8 is not greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com