An inter-board waveguide-fiber coupling system

A fiber coupling and waveguide technology, applied in the field of optical signal propagation, can solve the problems of complex preparation process, poor transmission consistency, and low assembly efficiency, and achieve the effects of high standardization, reduced installation space, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation manner, Features and their functions are described in detail below.

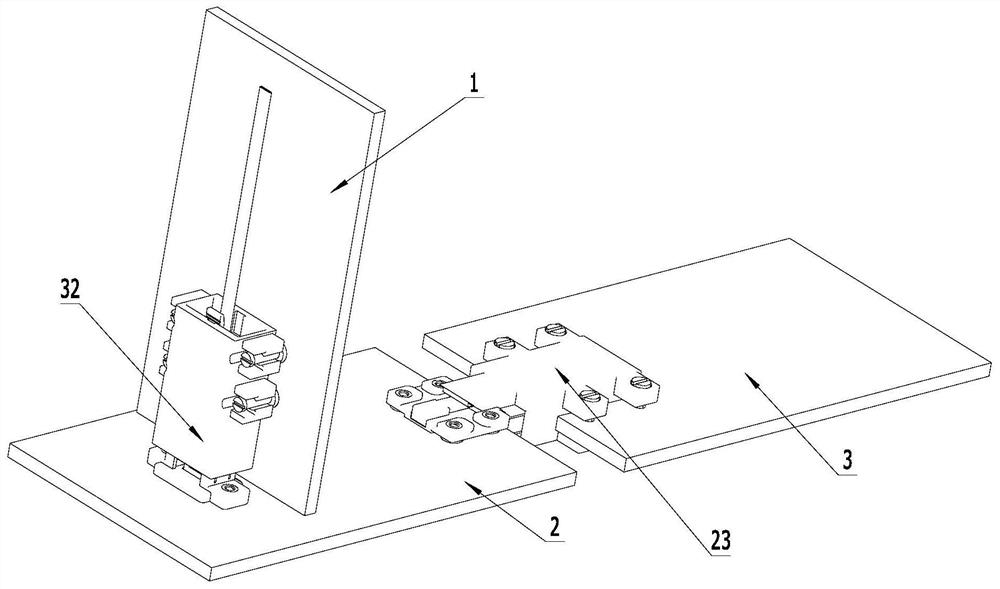

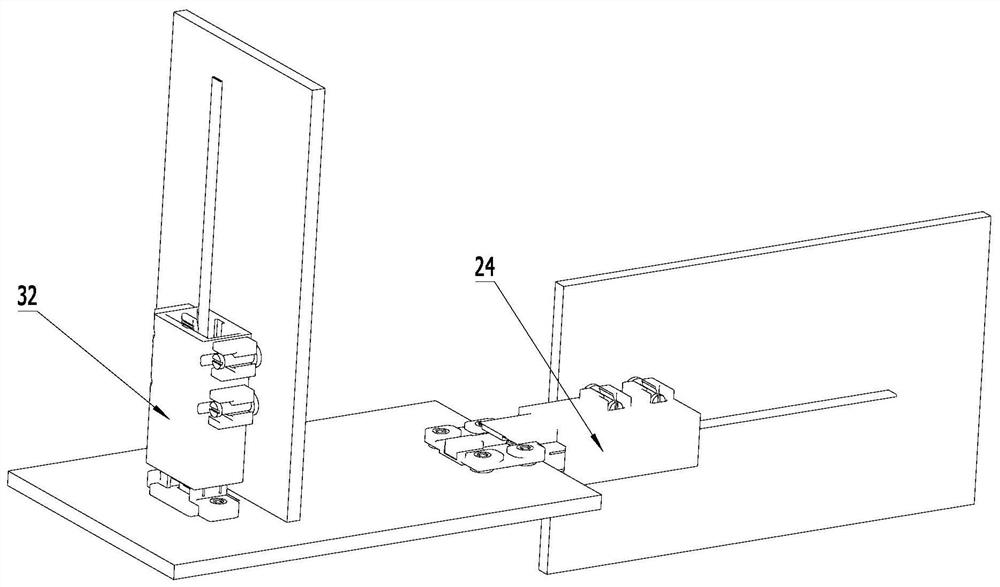

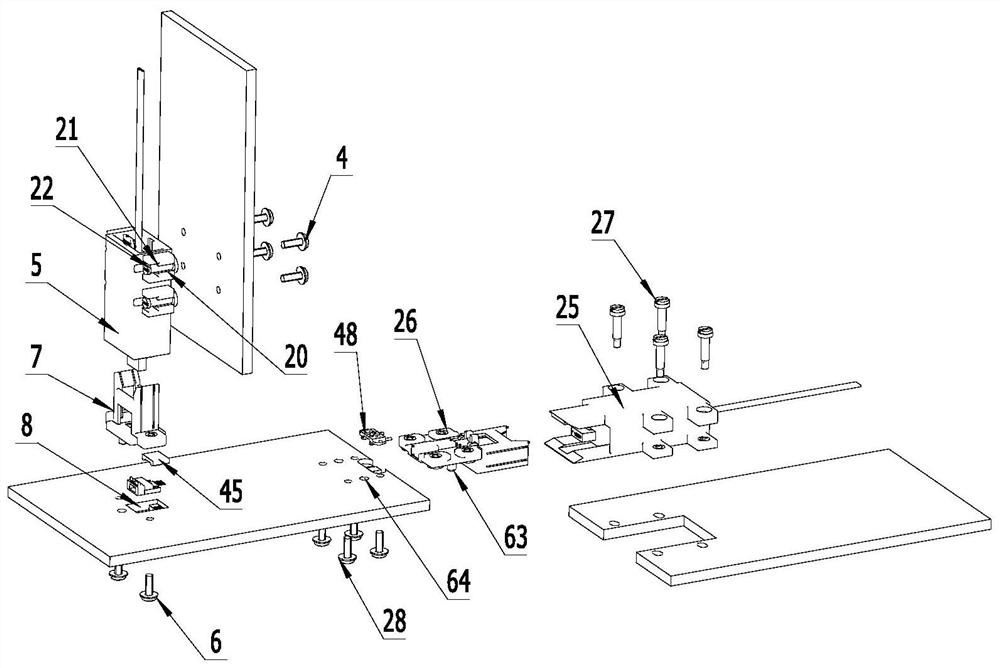

[0037] Such as figure 1 and figure 2 As shown, the present invention includes an adapter board 1, a waveguide backplane 2, and a sub-board 3. The board edge waveguide connectors are interconnected in parallel or vertically; the vertical waveguide connectors on the board include the vertical waveguide connector plug 5 fixed on the adapter board through the first screw assembly 4, and the vertical waveguide connector plug 5 fixed on the adapter board through the second screw assembly 6. On-board vertical waveguide connector sockets 7 on the waveguide backplane and vertical turning contacts fitted in the first waveguide port 8 of the waveguide backplane.

[0038] The vertical waveguide connector plug on the board includes an outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com