Method for machining concave reflection surface on side surface of optical waveguide based on laser stepped etching method

A technology of side processing and step reflection, which is applied in the coupling of optical waveguide, optical waveguide light guide, light guide, etc., can solve the problems of numerical aperture mismatch and low coupling efficiency, achieve high processing accuracy, improve coupling efficiency, and benefit the optical back The effect of board space integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] join Figure 8 , this embodiment proposes a processing flow for processing a concave reflective surface on the side of an optical waveguide based on a laser step etching method.

[0027] Firstly, determine a number of continuous sub-processing areas whose axes are in a straight line on the side of the optical waveguide, and these sub-processing areas form a total processing area; then, according to the specific concave shape etched (such as parabola, double Curve, arc, free curve), determine the maximum depth of each sub-processing area, in order to determine the number of steps, step width, and step depth to be processed in each sub-processing area; then, process each sub-processing area separately, specifically When etching, each sub-processing area determines at least two or partially overlapping areas, and the etching depth of the overlapping area is twice the etching depth of the non-overlapping area of the previous etching, thus forming a regular stepped reflect...

Embodiment 2

[0029] join Figure 1-Figure 9 , the present embodiment is basically the same as Embodiment 1, and its special features are as follows:

[0030] First, when the total processing area is guaranteed to be constant, the more the number of sub-processing areas is determined, the closer the processed stepped reflective concave surface is to the designed concave surface shape, and the better the reflective focusing effect will be.

[0031] Second, when selecting processing parameters, two processing methods can be selected to process the concave shape to be designed. One method is: control the number of steps to decrease in sequence, the step width to decrease in sequence, but the step depth is the same, and the other method It is: the number of control steps is the same, the step width is the same, but the step depth decreases successively.

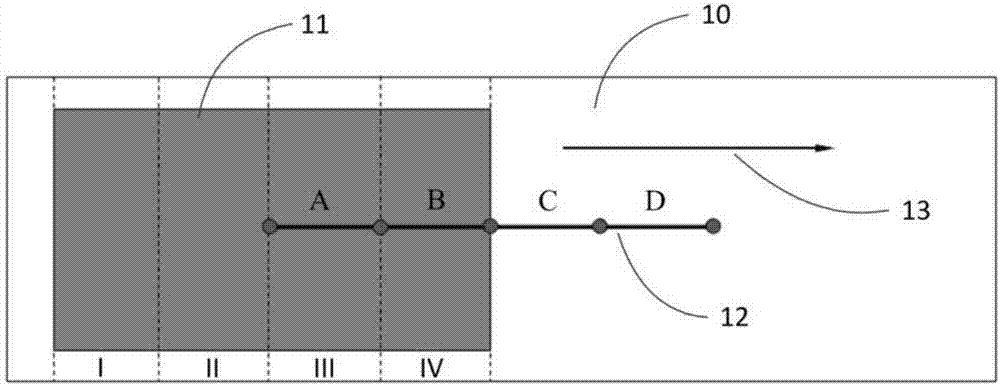

[0032] The third is to describe the specific etching process by determining 4 sub-processing areas with equal lengths. The total length of t...

Embodiment 3

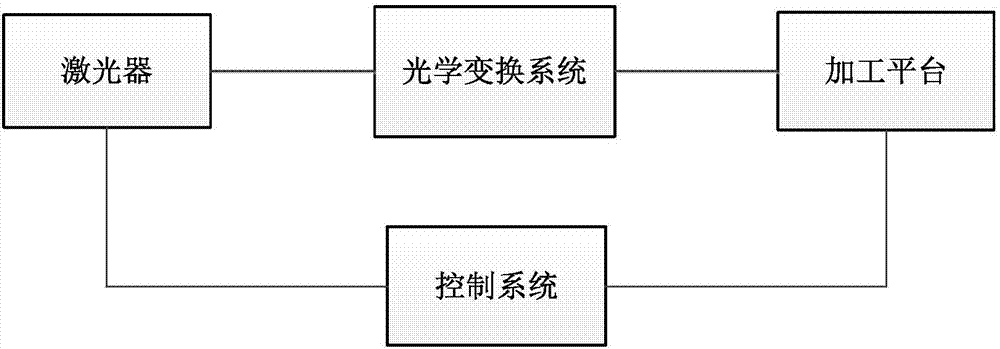

[0036] This embodiment provides a more specific method for processing a concave reflective surface on the side of an optical waveguide based on the laser step etching method. parameter optional, figure 1 A schematic diagram of the equipment system for concave machining is shown.

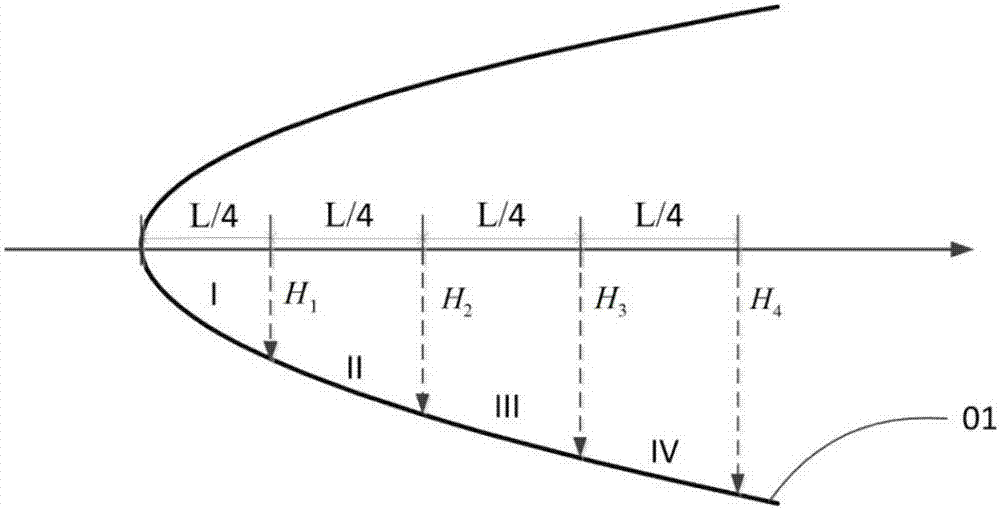

[0037] In this embodiment, a kind of similar etching is determined on the optical waveguide figure 2 As shown in the parabolic reflective surface 01, the parabolic reflective surface reflects the parallel beam parallel to the parabolic axis and converges the reflected beam to its focal point. The focal point position can be determined according to the actual requirements of the fiber-optical waveguide vertical coupling. When the focal point position After selection, the etched parabola is uniquely determined. figure 2 The example is divided into 4 equally spaced areas I, II, III, and IV on the parabola 010, and the maximum depth of each area is H 1 、H 2 、H 3 、H 4 . In the optical waveguide 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com